Method for preparing nano nickel powder

A technology of nano-nickel powder and nickel powder, applied in the field of nano-nickel powder, can solve the problems of difficult to realize industrialized production, high cost, easy oxidation of particles, etc., achieve uniform and stable growth environment, less environmental pollution, and improve power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

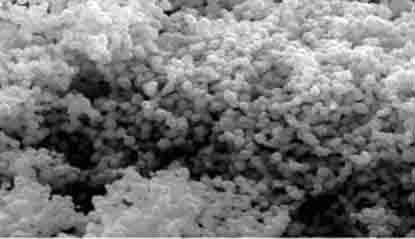

[0023] The present invention will be further described below in conjunction with all accompanying drawings, and preferred embodiment of the present invention is: at first take nickel sulfate, sodium hydroxide as raw material to prepare nickel hydroxide colloid; Then take hydrazine hydrate as reducing agent, by nickel hydroxide reduction reaction Production of nano nickel powder. During the reduction reaction process, by adding reduction promoters and catalysts, the reduction reaction of nickel hydroxide can be accelerated, the side reaction of hydrazine hydrate can be suppressed, and the hydrazine-nickel ratio can be reduced; at the same time, the fluidized reactor can be used to control the reaction residence time of nickel hydroxide to The purpose of controlling the particle size of the nano-nickel powder is to control the crystal morphology of the nickel hydroxide precursor by adding a crystal shape control agent, thereby controlling the morphology of the nickel powder.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com