Assembly block for artificially cultivating diamond

A technology of artificial cultivation and assembly of blocks, applied in the process of applying ultra-high pressure, methods of chemically changing substances using atmospheric pressure, chemical instruments and methods, etc. Problems such as poor stability and low percentage of finished products can achieve the effect of reducing mutual interference, good thermal insulation effect and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

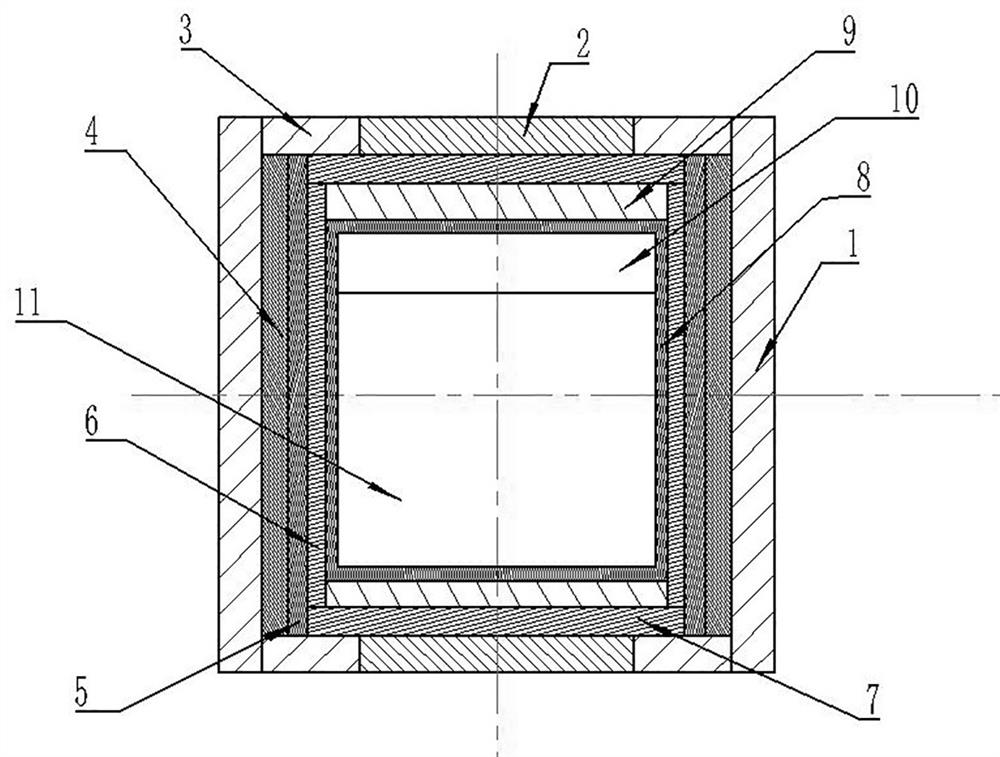

[0029] Such as figure 1 As shown, the artificially cultivated diamond assembly block provided by the present application can be divided into four layers of wrapping structures from inside to outside; wherein, the magnesium oxide layer 8 containing the raw material column in the center of the assembly block is used as the core first layer;

[0030] The raw material column is composed of a carbon source layer 10 placed on the upper layer and a graphite core column 11 placed on the lower layer;

[0031] The second layer is composed of: an insulating layer 9 designed on the upper and lower parts of the magnesium oxide layer 8, and a graphite tube 6 designed oppositely in the longitudinal direction;

[0032] The third layer is made up of: the NaCl tube 5 designed in the exterior design of the graphite tube 6 in the longitudinal direction, and the graphite sheet 7 designed in the transverse direction; meanwhile, the outer lining layer 4 is arranged outside the longitudinal NaCl tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com