Wind generating set adopting hydraulic buffer braking and locking

A technology of wind power generating set and hydraulic buffer, which is applied in the direction of wind power motor combination, wind power engine, wind power engine control, etc. It can solve problems such as brake disc wear, chassis vibration, and braking effect decline, so as to improve protection, avoid vibration, and ensure The effect of the braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

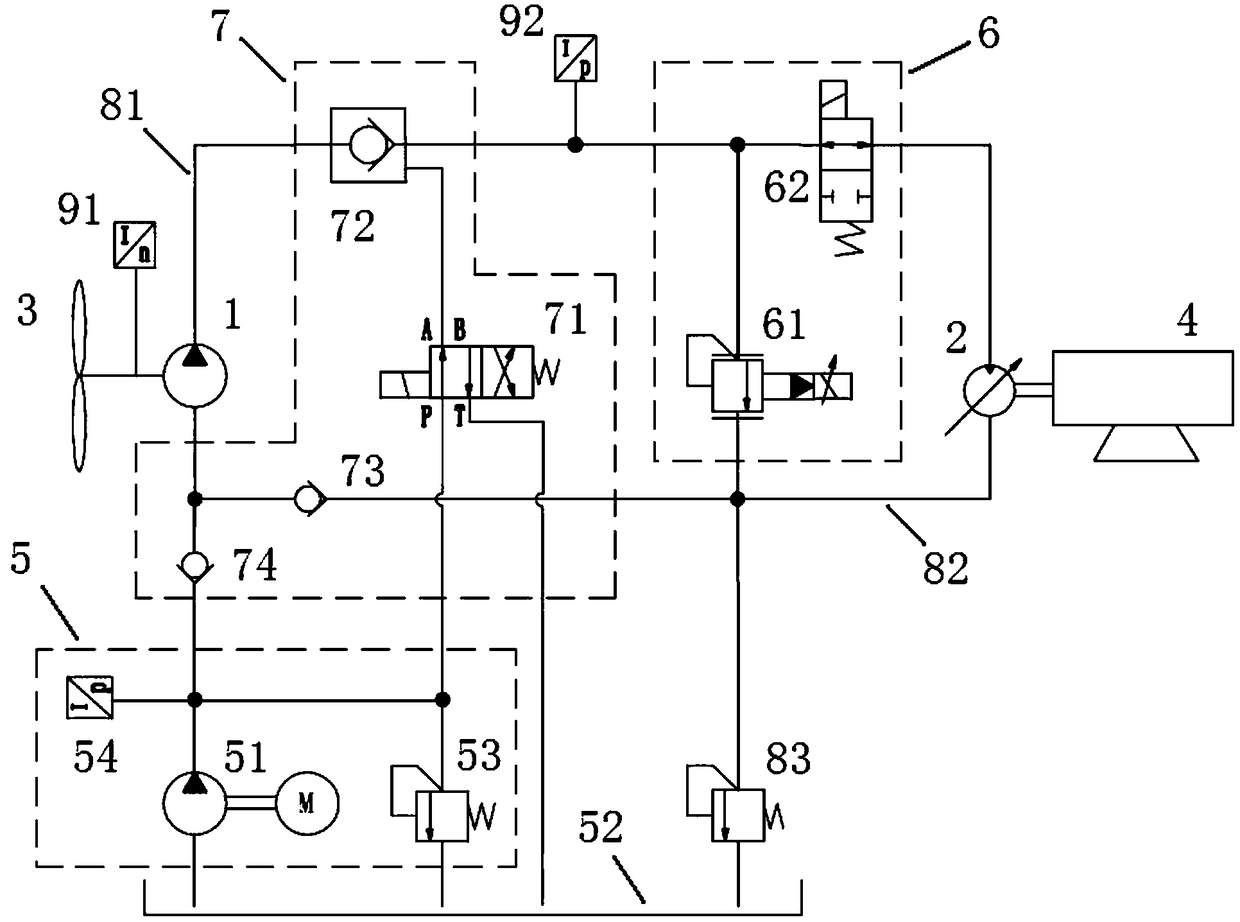

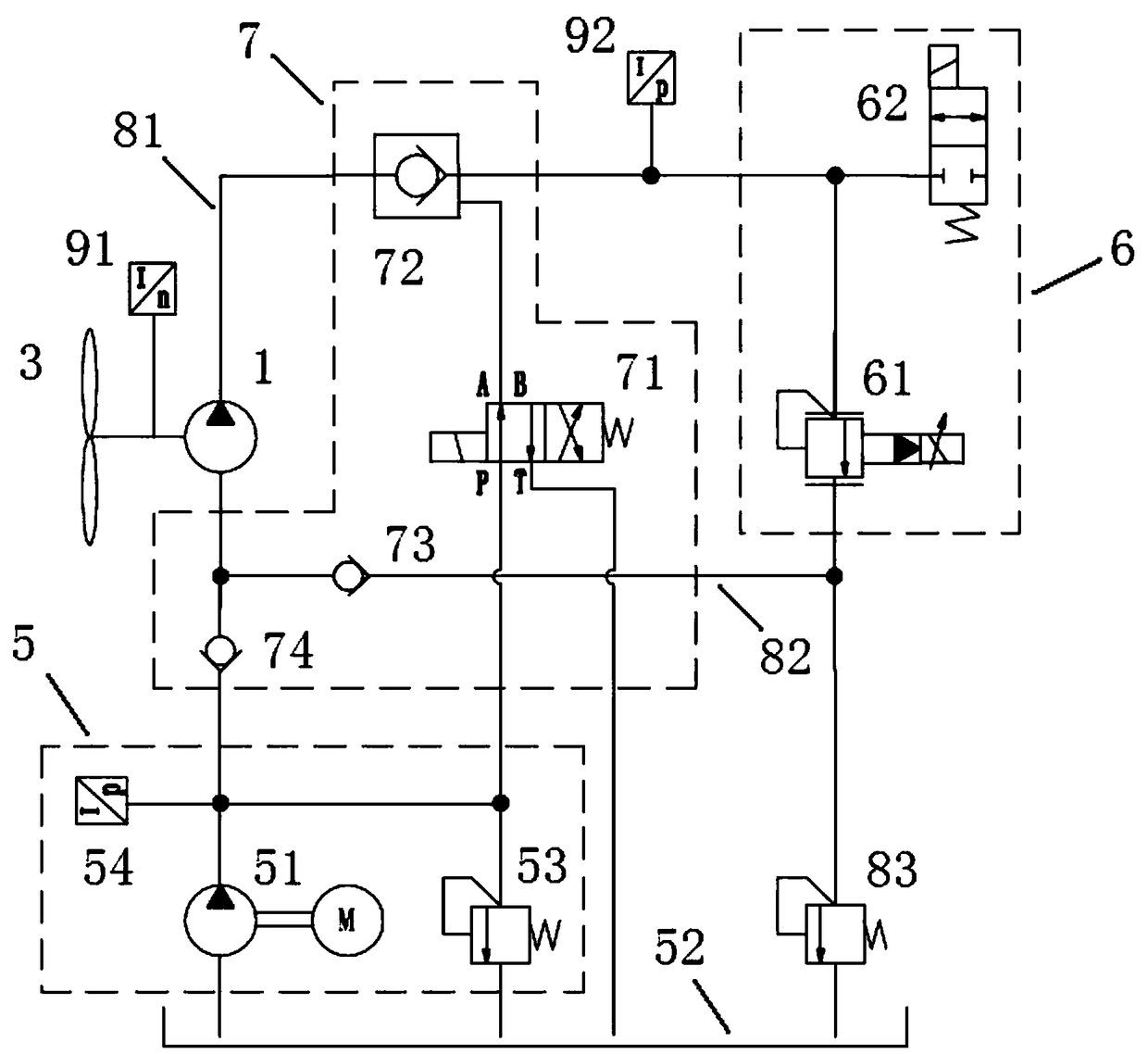

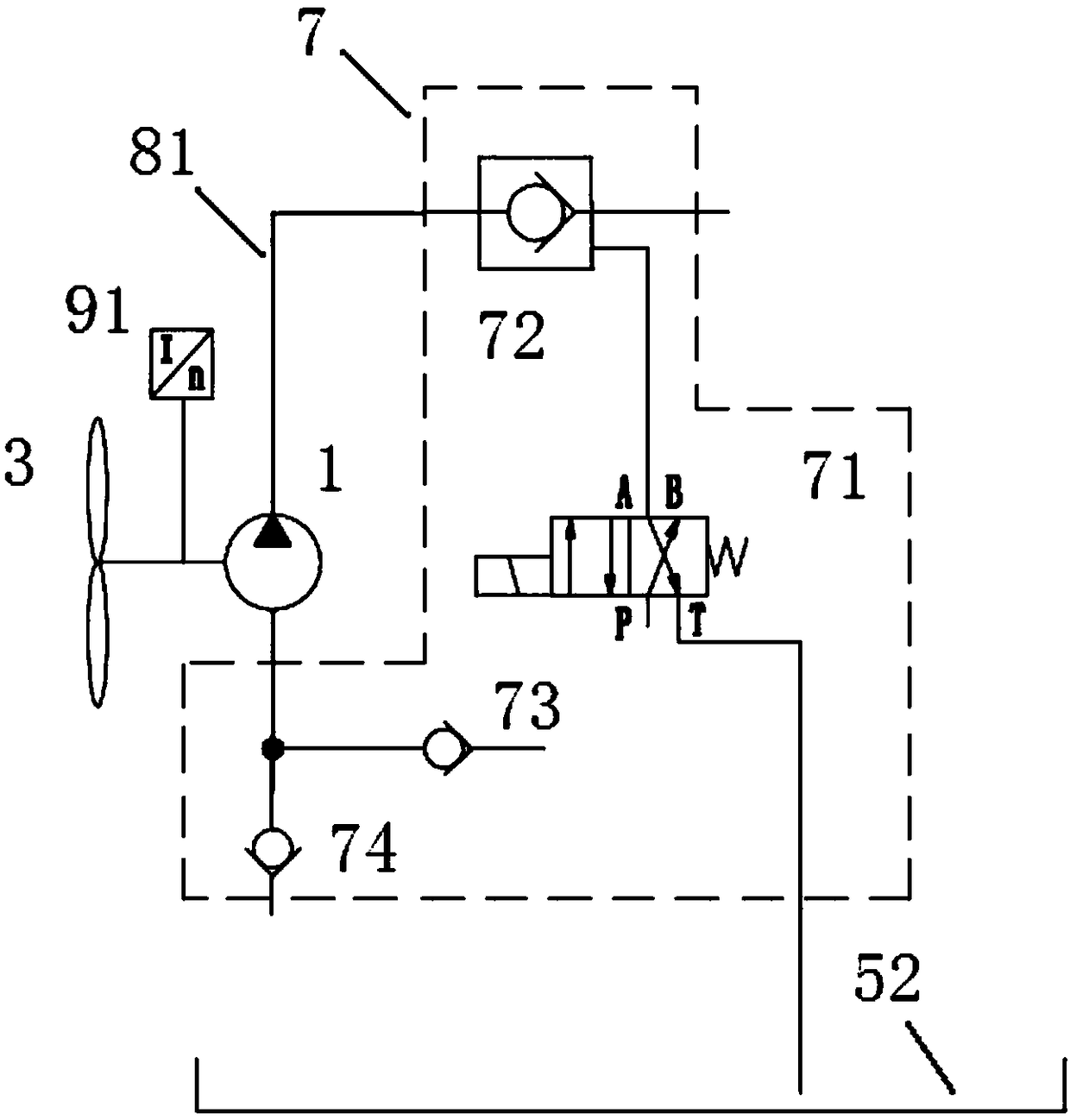

[0024] combine figure 1 As shown, the wind power generating set of the present invention includes a hydraulic pump 1 , a hydraulic motor 2 , a wind wheel 3 , a generator 4 , an oil supply unit 5 , a hydraulic buffer unit 6 and a hydraulic locking unit 7 .

[0025] The oil outlet of the hydraulic pump 1 is connected to the oil inlet of the hydraulic motor 2 through a high-pressure oil passage 81, and the oil outlet of the hydraulic motor 2 is connected to the oil inlet of the hydraulic pump 1 through a low-pressure oil passage 82, thereby Form a closed-loop main circulation system. The wind wheel 3 is connected with the input shaft of the hydraulic pump 1 , and the generator 4 is connected with the output shaft of the hydraulic motor 2 . At this time, the wind wheel 3 rotates under the drive of the external wind, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com