Extraction purification method of cobalt nickel hydroxide hydrochloric acid leaching solution

A technology of nickel-cobalt hydroxide hydrochloric acid and nickel-cobalt hydroxide is applied in the field of impurity removal of nickel-cobalt hydroxide hydrochloric acid leaching solution by extraction method, which can solve the problems of poor removal effect of metal ions and inability to meet electroplating-grade nickel chloride, etc. The effect of high impurity removal efficiency and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for extracting and removing impurities of nickel hydroxide cobalt hydrochloric acid leachate, it comprises the following steps:

[0028] Step 1: Pre-extract preparation. [H of industrial hydrochloric acid used + ] Concentration is 7.8mol / L, the pH value of hydrochloric acid leaching solution is 3.5, and the composition of used nickel hydroxide cobalt hydrochloric acid leaching solution is as shown in Table 3.

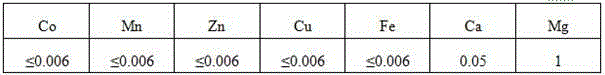

[0029] Table 3 Unit: g / L

[0030]

[0031] Step Two: Sodium Soap. Use P 507 As the extractant, the preparation ratio of the extracted organic phase is: 25%P 507 +75% solvent oil (volume ratio), prepared organic phase [H + ] Concentration is 0.68mol / L, adopts 30% liquid caustic soda to carry out saponification to organic, organic [H + ] The concentration is 0.15mol / L, and the organic phase formed is a sodium soap organic phase.

[0032] Step Three: Nickel Soap. The concentration of qualified nickel chloride solution used for nickel soap is cont...

Embodiment 2

[0039] A method for extracting and removing impurities of nickel hydroxide cobalt hydrochloric acid leachate, it comprises the following steps:

[0040] The first step: the [H of industrial hydrochloric acid used + ] Concentration is 8.1mol / L, the pH value of hydrochloric acid leaching solution is 4.0, and the composition of used nickel hydroxide cobalt hydrochloric acid leaching solution is as shown in table 5.

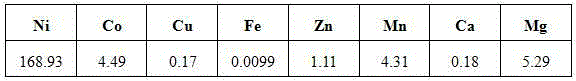

[0041] Table 5 Unit: g / L

[0042]

[0043] Step Two: Sodium Soap. Use P 507 As the extractant, the preparation ratio of the extracted organic phase is: 25%P 507 +75% solvent oil (volume ratio), prepared organic phase [H + ] Concentration is 0.70mol / L, adopts 30% liquid caustic soda to carry out saponification to organic, organic [H +] The concentration is 0.2mol / L, and the organic phase formed is a sodium soap organic phase.

[0044] Step Three: Nickel Soap. The concentration of qualified nickel chloride solution used for nickel soap is controlled at 88g / L,...

Embodiment 3

[0051] A method for extracting and removing impurities of nickel hydroxide cobalt hydrochloric acid leachate, it comprises the following steps:

[0052] Step 1: Pre-extract preparation. [H of industrial hydrochloric acid used + ] The concentration is 8.5mol / L, the pH value of the hydrochloric acid leaching solution is 3.5, and the components of the nickel hydroxide cobalt hydrochloric acid leaching solution used are as shown in Table 7.

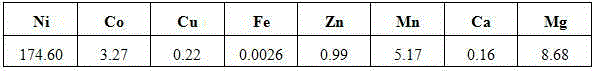

[0053] Table 7 Unit: g / L

[0054]

[0055] Step Two: Sodium Soap. Use P 507 As the extractant, the preparation ratio of the extracted organic phase is: 30%P 507 +70% solvent oil (volume ratio), prepared organic phase [H + ] Concentration is 0.75mol / L, adopts 30% liquid caustic soda to carry out saponification to organic, organic [H + ] The concentration is 0.22mol / L, and the organic phase formed is a sodium soap organic phase.

[0056] Step Three: Nickel Soap. The concentration of qualified nickel chloride solution used for nickel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com