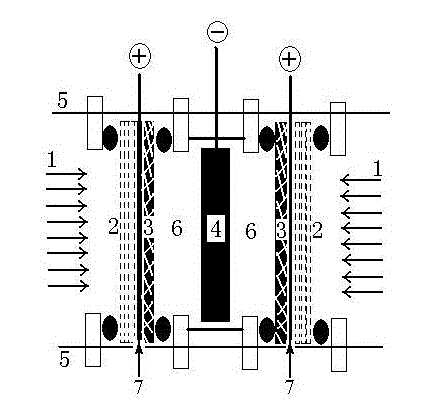

Maskless direct alcohol fuel cell and preparation method thereof

A fuel cell and manufacturing method technology, which can be used in fuel cells, solid electrolyte fuel cells, battery electrodes, etc., and can solve the problem of high cost of ion membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

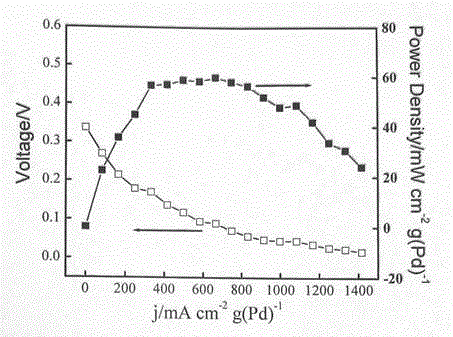

Embodiment 1

[0042] (1) Mix 0.1 g of multi-walled carbon nanotubes (MWCNTs) with 3 mmol L -1 PdCl 2 Solution 120 mL and 4 mmol·L -1 NiCl 2 After 20 mL of the solution was mixed, 50 mL of water was added to it, ultrasonicated for 30 min, and then stirred for 1 h. Then, under stirring, use 1mol·L -1 Adjust the pH value of the suspension to 8 with NaOH, and slowly add 3 mL of NaBH 4 (Percentage 50%) solution, continue stirring for 1 h after ultrasonication for 20 min. Washing with water twice and drying at 60 °C to obtain MWCNT-supported PdNi nano-catalyst particles (PdNi / MWCNT);

[0043] (2) 0.25 mmol silver nitrate and 0.3 mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of absolute ethanol, 77mg of treated carbon nanotubes were added, ultrasonicated for half an hour, and named as solution A. At the same time, weigh 2g of NaOH and dissolve it in 50ml of absolute ethanol, this is solution B. Slowly pour liquid B into liquid A under stirring, and it is found that flocculent subst...

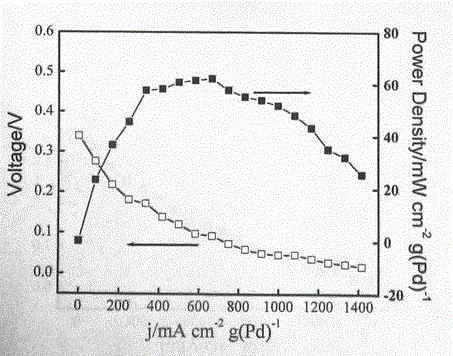

Embodiment 2

[0054] (1) Mix 0.15 g of multi-walled carbon nanotubes (MWCNTs) with 6 mmol L -1 PdCl 2 Solution 120mL and 10 mmol·L -1 NiCl 2 After 20 mL of the solution was mixed, 50 mL of water was added to it, ultrasonicated for 30 min and then stirred for 3 h. Then, under stirring, use 2mol·L -1 Adjust the pH value of the suspension to 8 with NaOH, slowly drop 5mLNaBH 4 (Percentage 50%) solution, continue stirring for 1 h after ultrasonication for 20 min. Washing with water twice and drying at 60 °C to obtain MWCNT-supported PdNi nano-catalyst particles (PdNi / MWCNT);

[0055] (2) 0.45 mmol silver nitrate and 0.5 mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of absolute ethanol, 77mg of treated carbon nanotubes were added, ultrasonicated for half an hour, and named as solution A. At the same time, weigh 2g of NaOH and dissolve it in 50ml of absolute ethanol, this is solution B. Slowly pour liquid B into liquid A under stirring, and it is found that flocculent substances are...

Embodiment 3

[0066] (1) Mix 0.30 g of multi-walled carbon nanotubes (MWCNTs) with 10 mmol L -1 PdCl 2 Solution 120mL and 15 mmol·L -1 NiCl 2 After 20 mL of the solution was mixed, 50 mL of water was added to it, ultrasonicated for 30 min, and then stirred for 5 h. Then, under stirring, use 3mol·L -1 Adjust the pH value of the suspension to 8 with NaOH, and slowly add 7 mL of NaBH 4 (Percentage 50%) solution, continue stirring for 1 h after ultrasonication for 20 min. Washing with water twice and drying at 60 °C to obtain MWCNT-supported PdNi nano-catalyst particles (PdNi / MWCNT);

[0067] (2) 0.65 mmol silver nitrate and 0.7 mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of absolute ethanol, 77mg of treated carbon nanotubes were added, ultrasonicated for half an hour, and named as solution A. At the same time, weigh 2g of NaOH and dissolve it in 50ml of absolute ethanol, this is solution B. Slowly pour liquid B into liquid A under stirring, and it is found that flocculent subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com