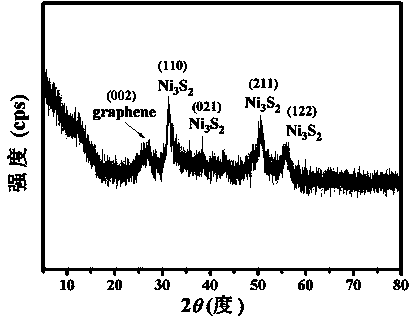

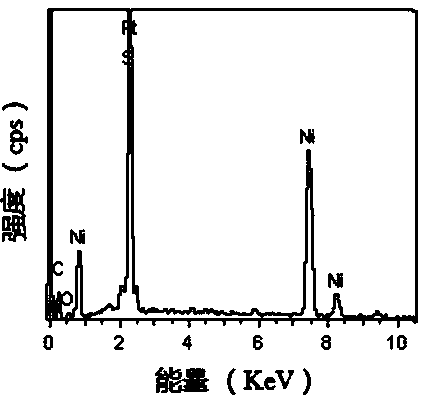

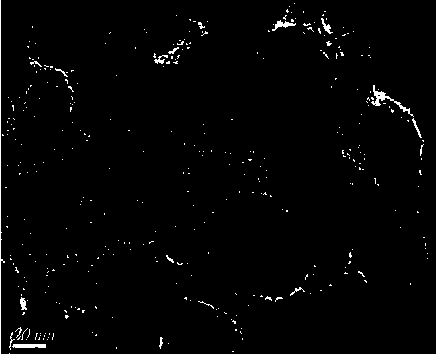

Method for preparing carbon-coated Ni3S2/graphene composite material for supercapacitor electrode

A graphene composite and supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of small specific capacitance and small specific capacitance of the composite, and increase the contact area between the electrode material and the solution, and achieve excellent capacitance performance, The effect of improving conductivity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: 20 mg of graphite oxide and 180 mg of glucose are dispersed in 20 mL of water and ethanol mixed solvent ( V 水 / V 乙醇 = 1 / 9), ultrasound forms a uniform dispersion. Then add 1.50 mmol NiCl 2 . 6H 2 O and 1.00 mmol thiourea, stirred thoroughly, and then added 2 mL of ammonia water with a concentration of 15 mol / L; o C was reacted for 12 h, and the obtained black product was separated by centrifugation, washed three times with water and ethanol respectively, and finally at 45 o C under vacuum.

Embodiment 2

[0024] Embodiment 2: 20 mg graphite oxide and 180 mg glucose are dispersed in 20 mL of water and ethanol mixed solvent ( V 水 / V 乙醇 = 1 / 9), ultrasound forms a uniform dispersion. Then add 1.00 mmol NiCl 2 . 6H 2 O and 0.667 mmol thiourea, stirred thoroughly, and then added 2 mL of ammonia water with a concentration of 15 mol / L; transferred the mixed solution to a 30 mL reaction kettle, and o C was reacted for 12 h, and the obtained black product was separated by centrifugation, washed three times with water and ethanol respectively, and finally at 45 o C under vacuum.

Embodiment 3

[0025] Embodiment 3: 20 mg graphite oxide and 180 mg glucose are dispersed in 20 mL of water and ethanol mixed solvent ( V 水 / V 乙醇 = 1 / 9), sonicate to form a uniform dispersion, and then add 2.00 mmol NiCl 2 . 6H 2 O and 1.33 mmol thiourea, stirred thoroughly, and then added 2 mL of ammonia water with a concentration of 15 mol / L; o C was reacted for 12 h, and the obtained black product was separated by centrifugation, washed three times with water and ethanol respectively, and finally at 45 o C under vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com