Nickel-filled nitrogen-doped carbon nanotubes as well as preparation method and application thereof

A technology of nanotubes and nitrogen-carbon, applied in the field of nickel-filled nitrogen-doped carbon nanotubes and its preparation, can solve the problems of restricting the industrial application of nickel-filled carbon nanotubes, harsh reaction conditions, cumbersome preparation process, etc., and achieve excellent oxygen reduction electricity The effect of catalytic performance, low equipment requirements and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this example, melamine is used as a carbon and nitrogen source to prepare nickel-filled nitrogen-doped carbon nanotubes, and the following operations are performed in sequence:

[0035] (1) Disperse 2.0 g of nickel chloride and 4.0 g of melamine in 20 mL of absolute ethanol, stir and then sonicate for 15 min, put it in a drying oven at 100 ° C for 5 h to obtain a solid mixture, and grind to obtain a mixed powder.

[0036] (2) Put the mixed powder into a porcelain boat and place it in a high-temperature tube furnace. Nitrogen was introduced at a rate of 150 mL / min, the temperature was raised to 800 °C at a rate of 6 °C / min, calcined for 1 hour, and naturally cooled to room temperature to obtain a black powder.

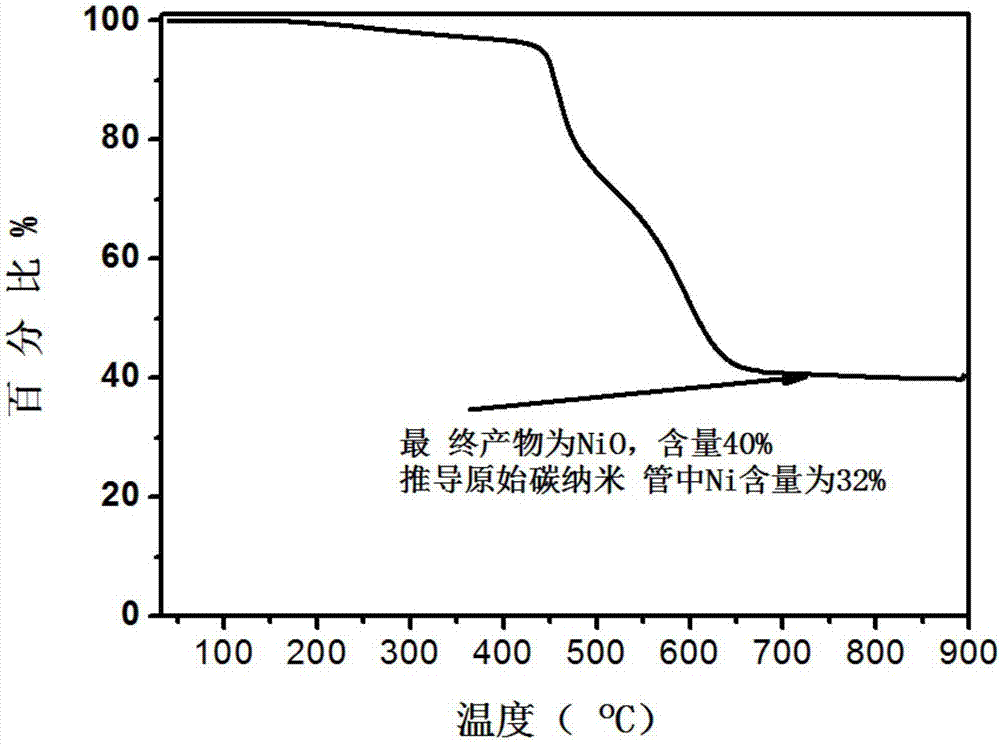

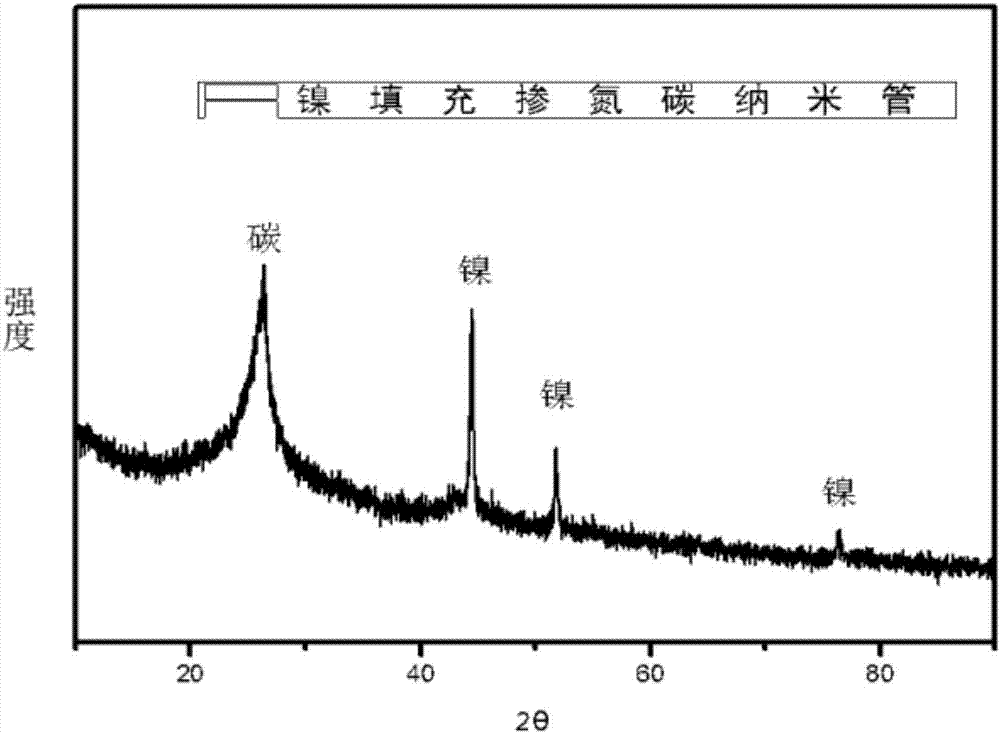

[0037] (3) Put the black powder into 10 mL of hydrochloric acid with a substance concentration of 1 mol / L, stir for one and a half hours, let stand for 1 to 2 days, and filter and dry to obtain nickel-filled nitrogen-doped carbon nanotubes, the final product ...

Embodiment 2

[0040] In this example, melamine is used as a carbon and nitrogen source to prepare nickel-filled nitrogen-doped carbon nanotubes, and the following operations are performed in sequence:

[0041] (1) Disperse 2.0 g of nickel chloride and 6.0 g of melamine in 20 mL of absolute ethanol, stir, then sonicate for 20 min, dry in an oven at 90°C for 6 h to obtain a solid mixture, and grind to obtain a mixed powder.

[0042] (2) Put the mixed powder into a porcelain boat and place it in a high-temperature tube furnace. Nitrogen was introduced at a rate of 150 mL / min, the temperature was raised to 900 °C at a rate of 8 °C / min, calcined for 2 hours, and naturally cooled to room temperature to obtain a black powder.

[0043] (3) Put the black powder into 10 mL of hydrochloric acid with a substance concentration of 0.5 mol / L, stir for one and a half hours, let stand for 1 to 2 days, filter and dry with suction to obtain nickel-filled nitrogen-doped carbon nanotubes.

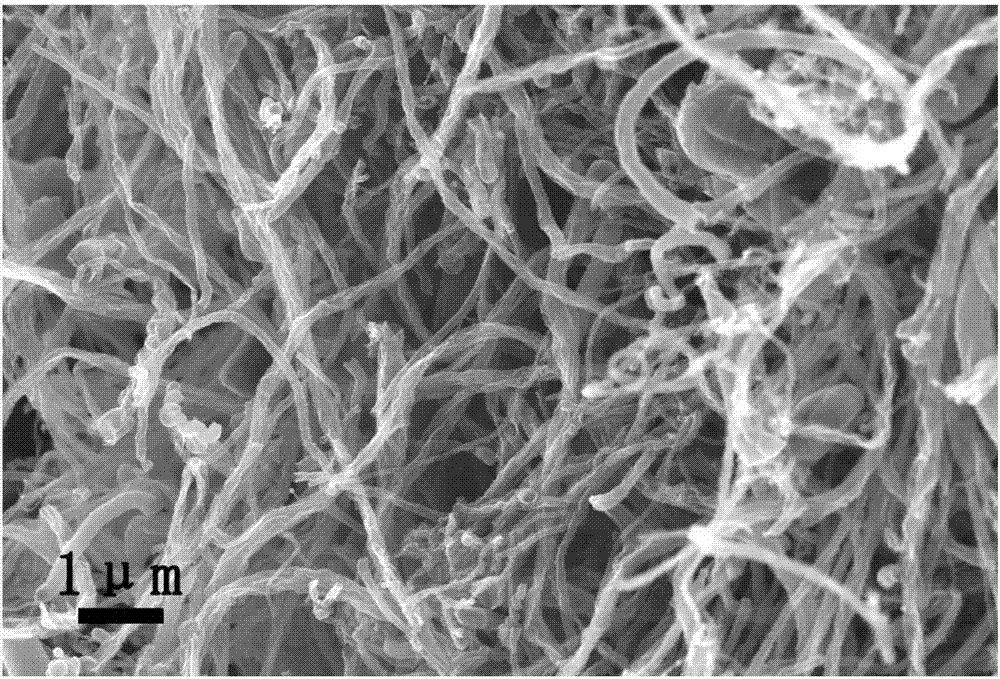

[0044] The SEM of t...

Embodiment 3

[0048] In this embodiment, dicyandiamide is used as a carbon and nitrogen source to prepare nickel-filled nitrogen-doped carbon nanotubes, and the following operations are performed in sequence:

[0049] (1) Disperse 2.0g of nickel chloride and 2.0g of dicyandiamide in 20mL of absolute ethanol, stir and then ultrasonic for 30min, put it in a drying oven at 110°C for 8h to obtain a solid mixture, and grind to obtain a mixed powder .

[0050] (2) Put the mixed powder into a porcelain boat and place it in a high-temperature furnace. Nitrogen was introduced at a rate of 150 mL / min, the temperature was raised to 700 °C at a rate of 10 °C / min, calcined for 2 hours, and naturally cooled to room temperature to obtain a black powder.

[0051] (3) Put the black powder into 10 mL of hydrochloric acid with a substance concentration of 1 mol / L, stir for one and a half hours, let stand for 1 to 2 days, filter and dry with suction to obtain nickel-filled nitrogen-doped carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com