Double-winch synchronous control system

A synchronous control, double hoisting technology, applied in the direction of fluid pressure actuating device, servo motor, mechanical equipment, etc., can solve the problems of affecting the quality of the trough, affecting the verticality of the grab, and low quality of the trough, and achieve synchronous speed regulation. The performance is stable and reliable, the pipeline connection is simple, and the effect of improving the quality of the groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

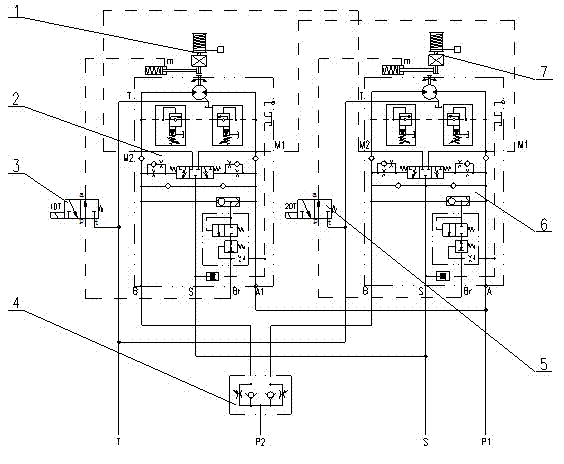

[0012] Such as figure 1 It is a schematic diagram of the structure of the present invention, a double winch synchronous control system, including front winch 1, rear winch 7, front balance valve 2, rear balance valve 6, front two-position three-way solenoid valve 3, and rear two-position three-way solenoid valve Through solenoid valve 5 and one-way speed control valve group 4, front hoist 1 and rear hoist 7 are equipped with balance valve 2 respectively, and one-way speed control valve group 4 is connected to the lifting of front hoist 1 and rear hoist 7 On the oil circuit, the front two-position three-way solenoid valve 3 is connected between the Br port of the front winch 1 motor and the brake port m of the reducer, and the rear two-position three-way solenoid valve 5 is connected to the Br port of the rear winch motor and the deceleration mechanism. Between the moving opening m, the two M2 ports of the front hoist 1 and the rear hoist 2 are connected, and the two M1 ports of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com