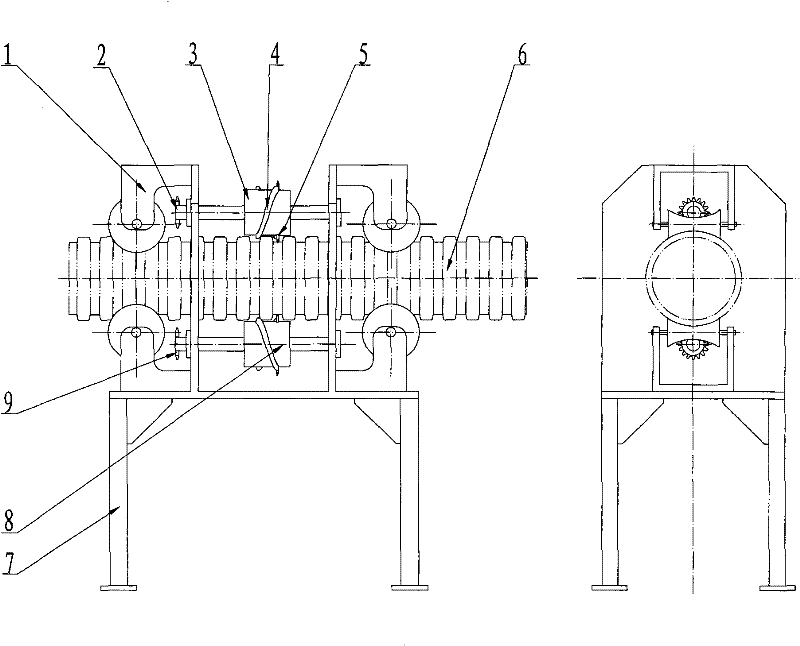

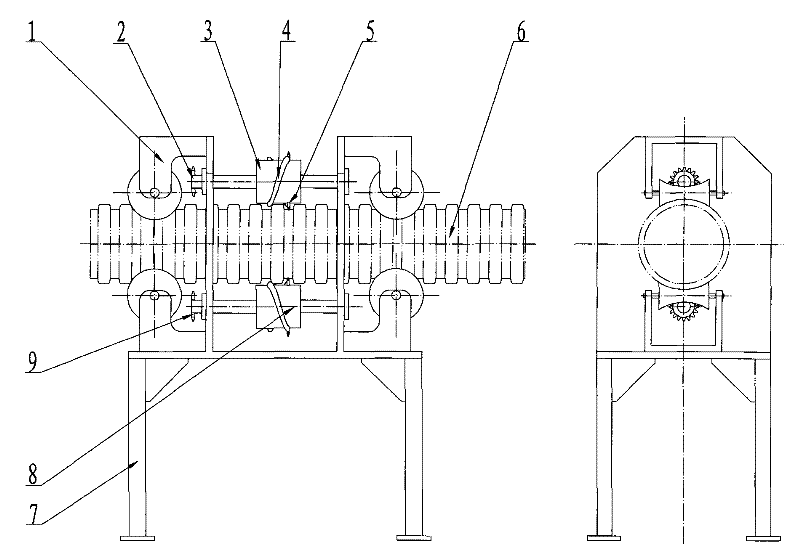

Worm-type plastic corrugated pipe grooving machine

A corrugated pipe and slotting machine technology, applied in metal processing, etc., can solve the problems of reducing scrap rate and slotting efficiency, volume and cost reduction, etc., to achieve increased production efficiency, reduced product scrap rate, and high slotting quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The plastic corrugated pipe (6) is clamped by two sets of guide wheels (1) for center positioning, and can move axially forward and backward. The upper knife bar (3) and the lower knife bar (8) are respectively fixed with forward and reverse rotation Worm screw curve (4), the end of worm screw curve (4) is respectively equipped with a piece of alloy cutter head (5), the crest of worm screw curve (4) and plastic corrugated pipe (6) engages, upper cutter bar (3) and lower cutter bar ( The two ends of 8) are supported on the front and rear wall panels on the frame (7) through bearings, and the upper drive sprocket (3) and the lower drive sprocket (3) are respectively installed on the front of the upper knife bar (3) and the lower knife bar (8). Sprocket wheel (9), input a direction of rotation opposite to upper transmission sprocket wheel (3) and lower transmission sprocket wheel (9) respectively, the same power of rotating speed, positive on the upper cutter bar (3) and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com