Automatic inclination correcting method and device

An automatic deviation correction and deviation correction technology, which is applied in the field of automatic deviation correction, can solve the problems that the working track of the deviation correction precision milling tool holder is not easy to maintain on the construction center line, the work efficiency is low, and the quality of the grooves is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

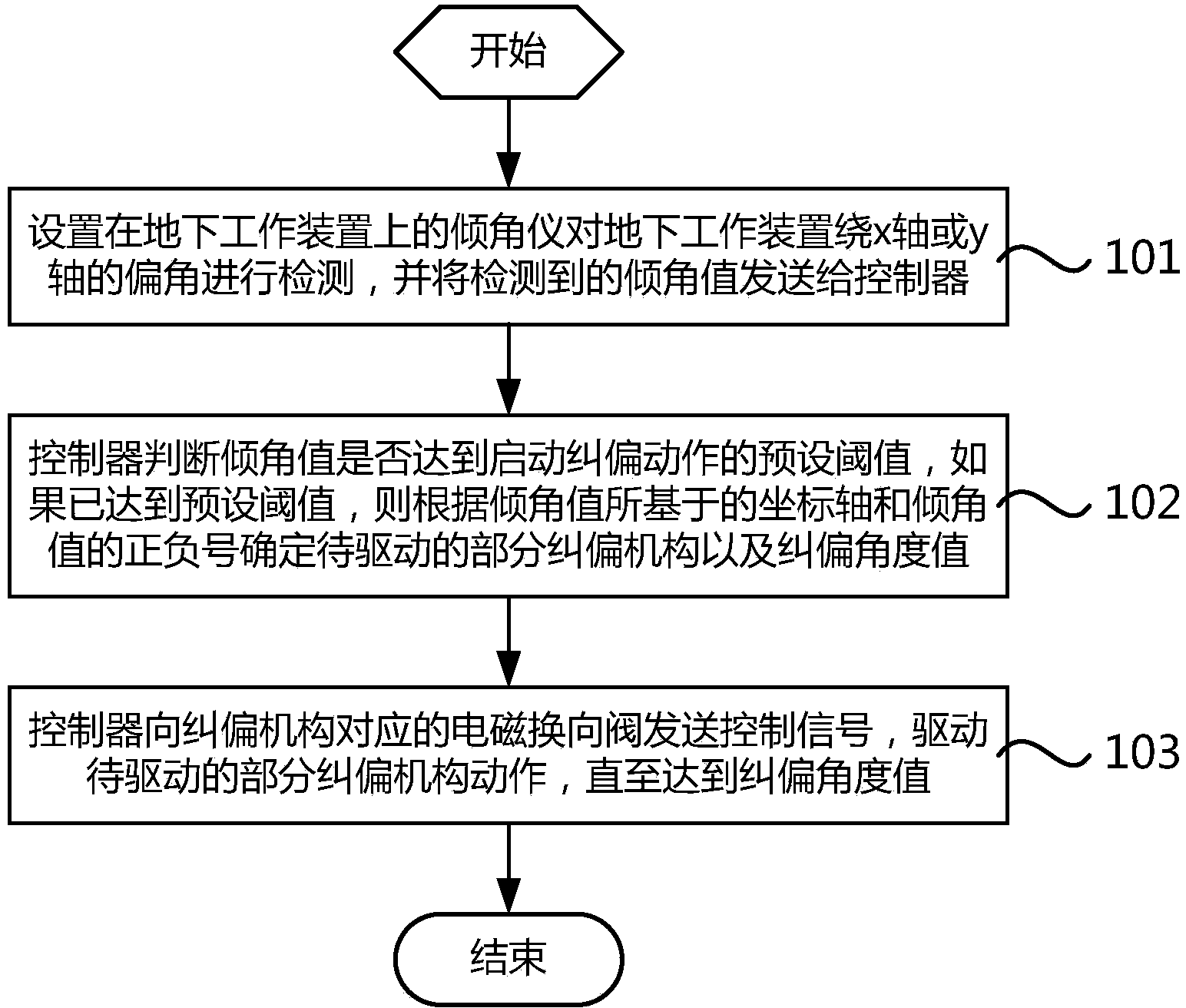

[0043] like image 3 As shown, it is a schematic flow chart of an embodiment of the automatic deviation correction method of the present invention. In this embodiment, the automatic deviation correction method includes a deviation correction process of the deflection angle of the underground working device around the x-axis or y-axis, specifically including:

[0044] Step 101. The inclinometer installed on the underground working device detects the deflection angle of the underground working device around the x-axis or y-axis, and sends the detected inclination value to the controller;

[0045] Step 102, the controller judges whether the inclination value has reached the preset threshold value for starting the deviation correction action, and if it has reached the preset threshold value, then determine according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com