Ballastless track deviation rectifying system and pushing device

A ballastless track and jacking device technology, applied in tracks, track laying, track maintenance, etc., can solve the problems of poor unilateral monitoring accuracy, high labor costs, and difficulty in controlling the deviation correction and pushing force, and achieve stable operation and layout. Reasonable and high accuracy of deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

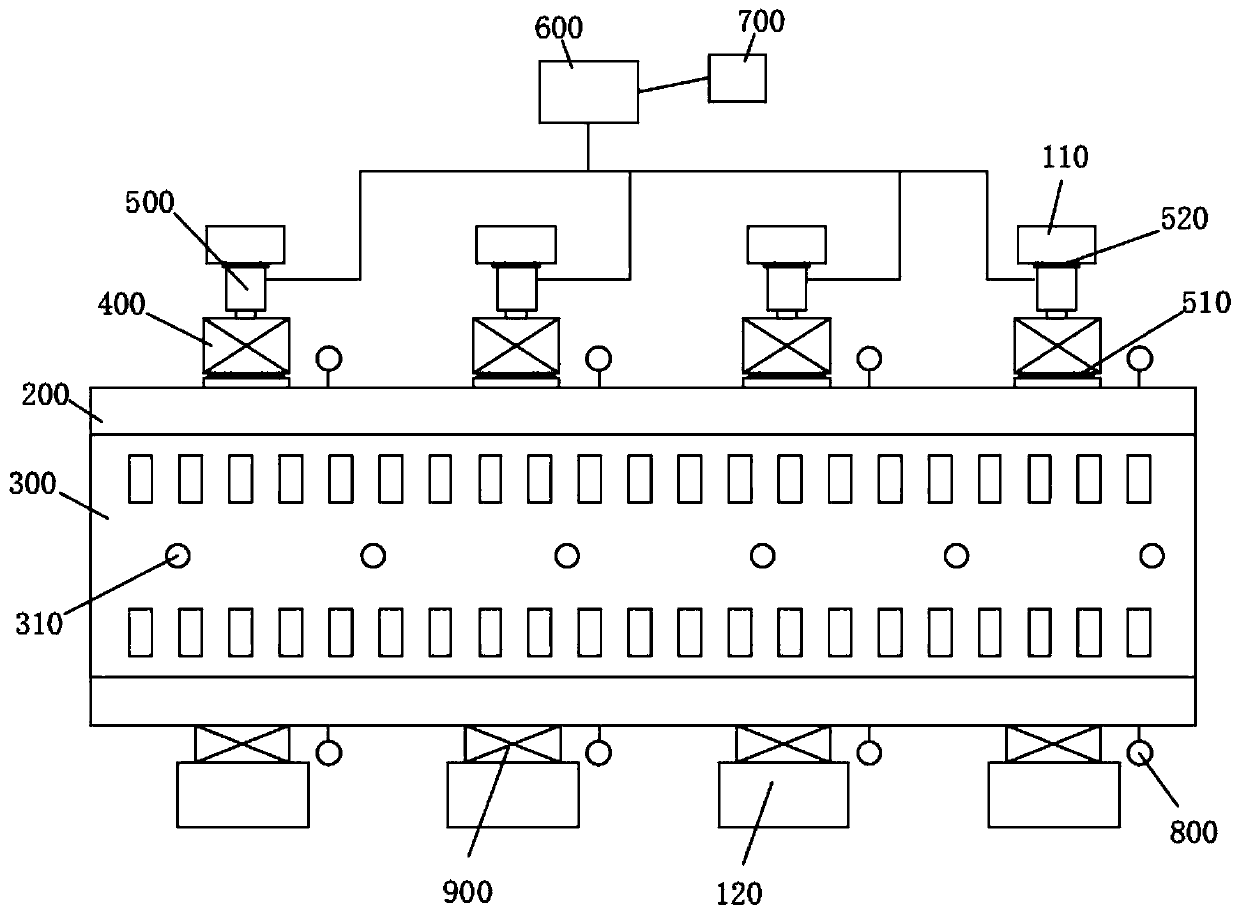

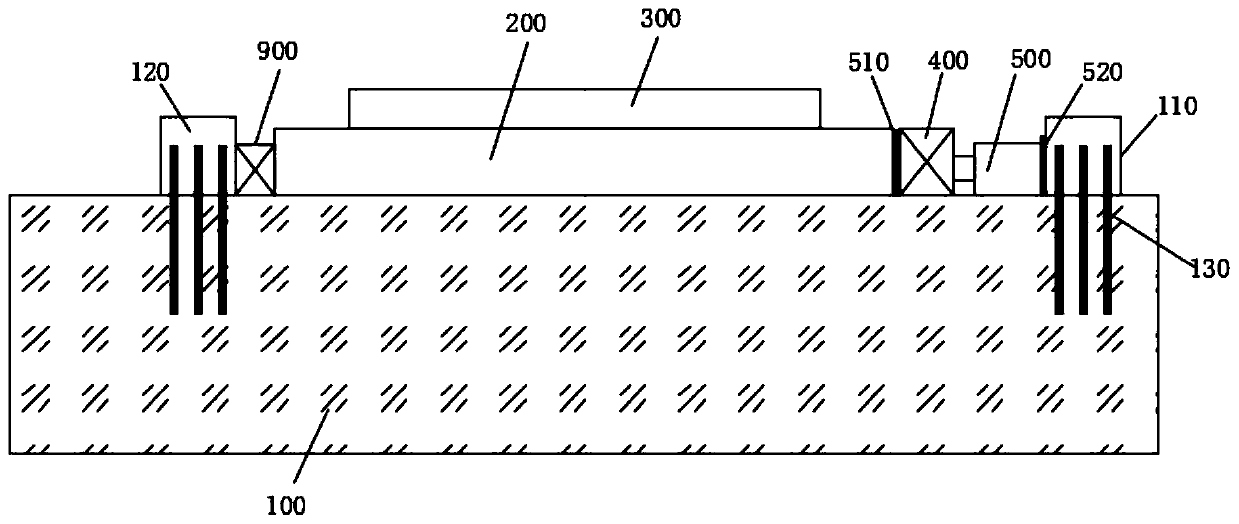

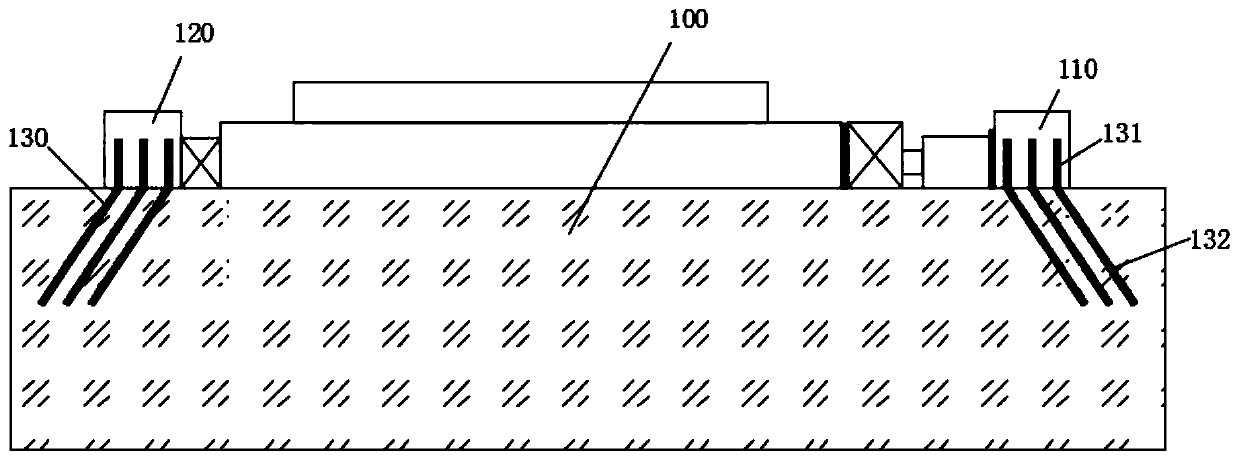

[0023] refer to Figure 1-3 In this embodiment, a ballastless track correction system is proposed. The ballastless track includes a support layer 200 and a ballastless track slab 300. The ballastless track slab 300 is laid on the support layer 200, and the support layer 200 is laid on the roadbed 100. , the correction system includes a pushing device 500, the pushing device 500 is arranged on one side of the supporting layer 200, the pushing direction of the pushing device 500 is consistent with the width direction of the supporting layer 200, the supporting layer 200 is equipped with a displacement sensor 800, and the pushing device 500 and the displacement sensor 800 are connected to the controller 700.

[0024] The pushing devices 500 are arranged at intervals along the length direction of the support layer 200 .

[0025] The displacement sensors 800 are arranged on both sides of the support layer 200 , and the displacement sensors 800 on the same side are distributed at i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com