Construction method of underground diaphragm wall in water-rich silty-fine sand layer

A water-rich powder fine sand layer and underground continuous wall technology, which can be used in excavation, sheet pile walls, foundation structure engineering, etc., and can solve the problems of increased construction costs and poor treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention.

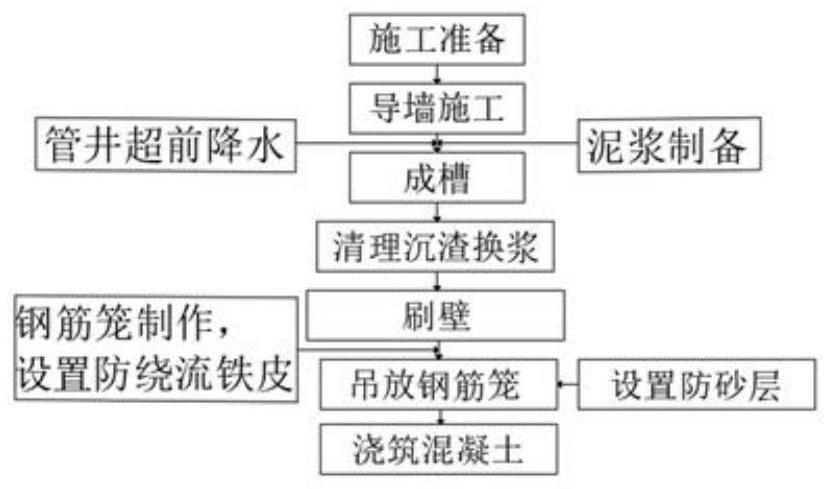

[0030] Such as figure 1 As shown, the construction method of a kind of water-rich powder fine sand layer underground continuous wall disclosed by the present invention comprises the following steps:

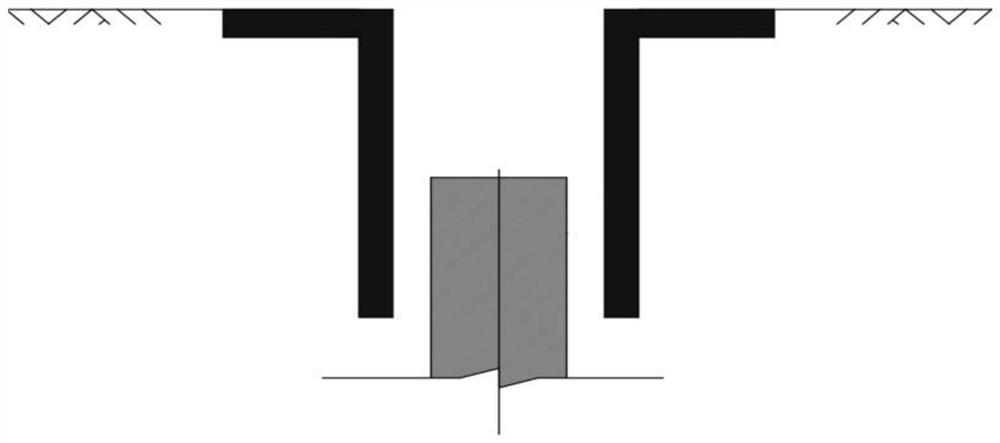

[0031] a. Guide wall construction, the sequence is: measurement and positioning, excavation, binding steel bars, formwork support, pouring, and formwork removal.

[0032] Technical points and construction points of guide wall:

[0033] The guide wall is the reference object of the underground diaphragm wall on the ground surface. During the construction period, the guide wall must bear the static and dynamic loads of the steel cage, the conduit for pouring concrete, and the drilling rig, and at the same time ensure the accuracy of the construction position of the underground diaphragm wall. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com