Grooving equipment for processing stainless steel and grooving technology thereof

A technology of stainless steel and stainless steel plate, which is applied in metal processing equipment, planing machines, metal processing machinery parts, etc. It can solve the problems of affecting the service life of the planer, difficulty in centering the planer bottom, and poor chip removal effect. Good groove effect, good fixing effect, and the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

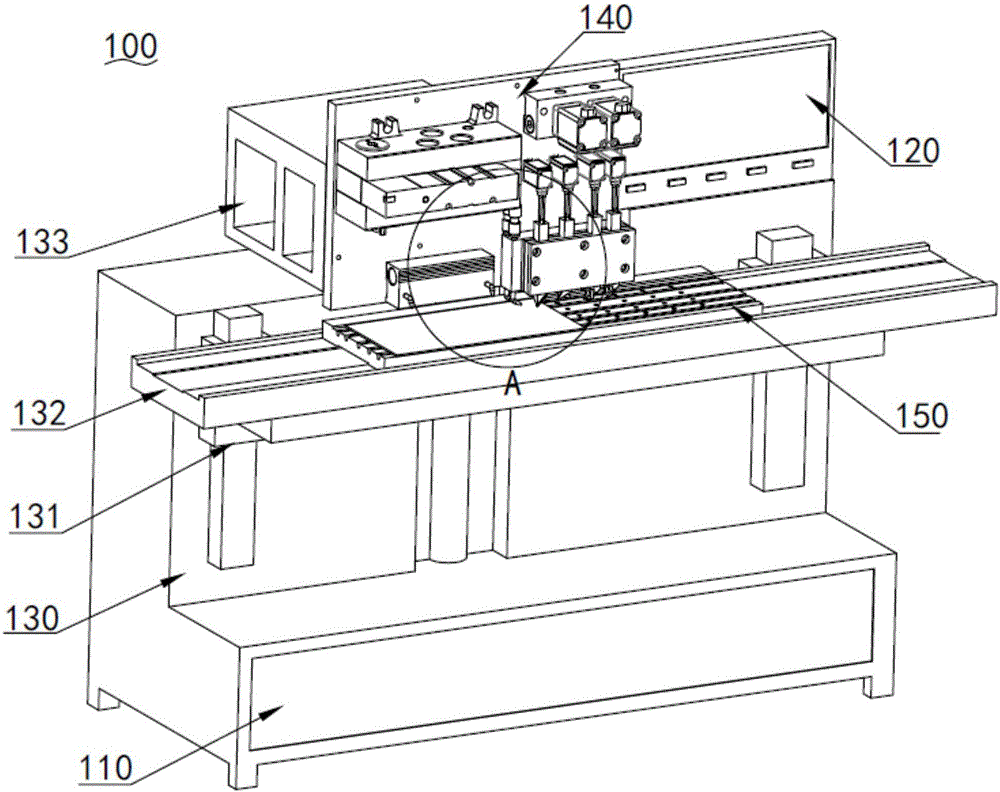

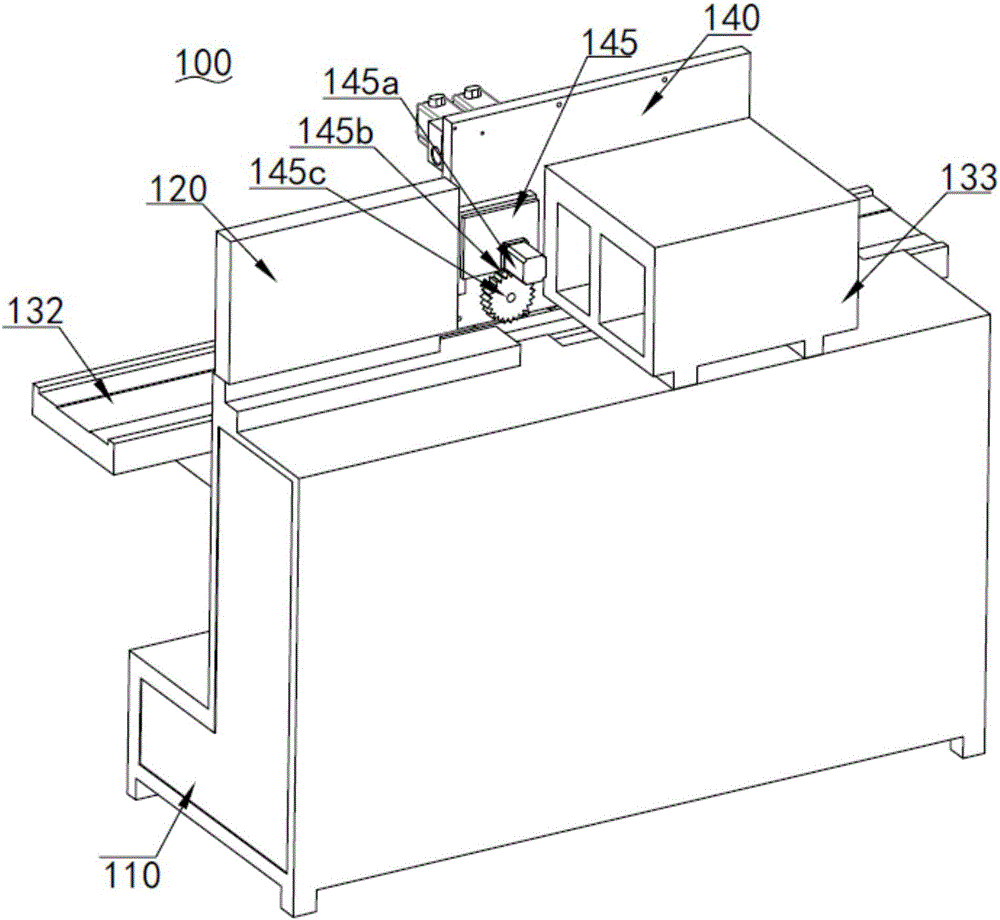

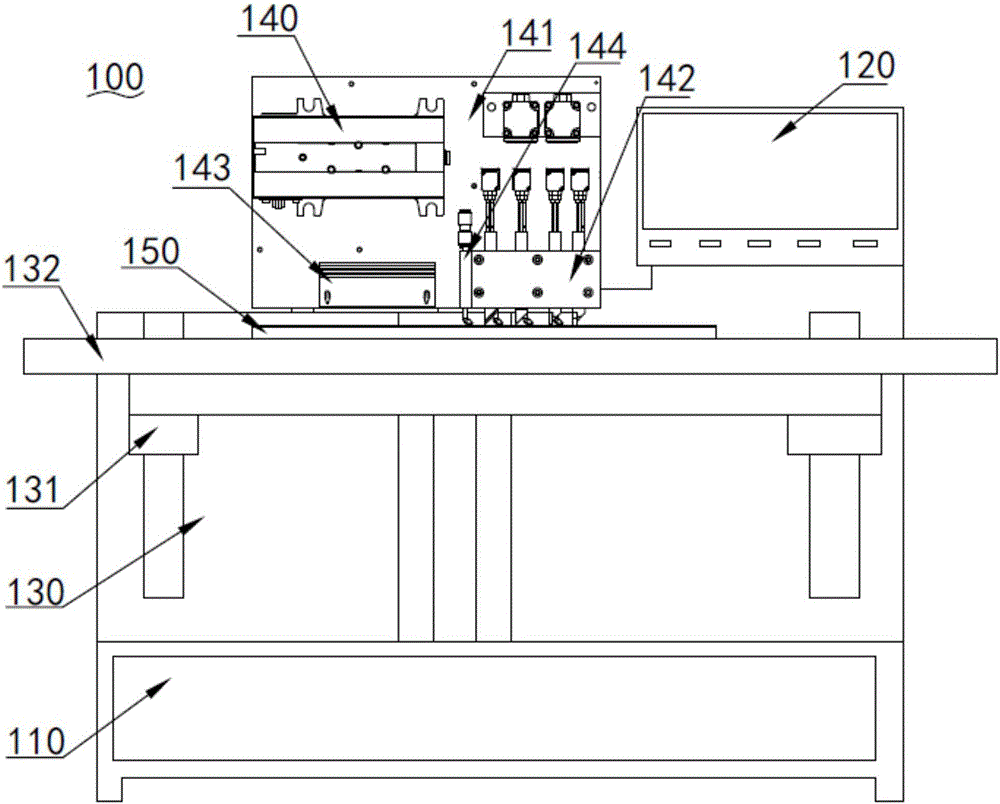

[0040] like Figure 1~4 Shown are respectively the perspective view, the front view and the enlarged view of different viewing angles of the present invention.

[0041] A grooving equipment 100 for stainless steel processing, which is provided with a frame 110, a control assembly 120, a power assembly 130 and a grooving assembly 140, the control assembly 120 and the power assembly 130 are installed on the frame 110, and the power assembly 130 It includes a lifting module 131, a conveying module 132 and a propulsion module 133, the planing module 140 is installed on the propulsion module 133, the conveying module 132 is equipped with a placement table 150, and the conveying module 132 is installed on the lifting module 133. Module 131, the planing assembly 140 is located above the placement table 150, the planing assembly 140 includes a mounting plate 141, a planing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com