Groove pressing structure of plate bending machine

A bending machine and grooving technology, which is applied in the field of grooving structure of a plate bending machine, can solve the problems of low processing accuracy, poor dimensional and quality of grooving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

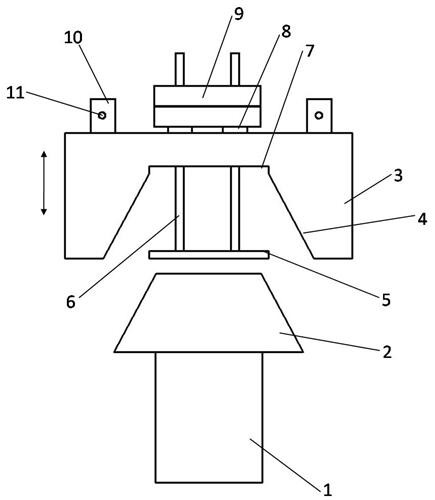

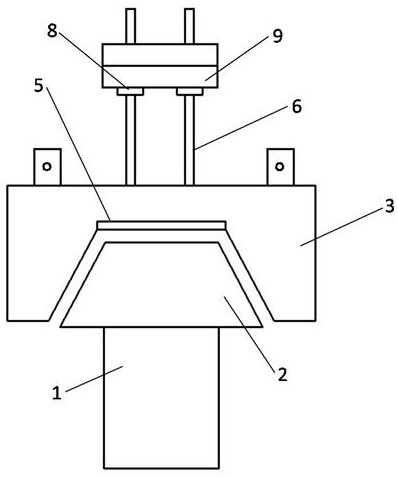

[0022] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

[0023] Such as Figure 1~2 As shown, a pressure groove structure of a plate bending machine includes a constant pressure table 1 on the workbench of the plate bender and a dynamic pressure head 3 moving toward or away from the constant pressure table 1. The upper end of the constant pressure table 1 is provided with a fixed Indenter 2, in the dynamic indenter 3 is formed a matching groove 4 that matches the fixed indenter 2, and four through holes are formed in the bottom of the indenter 4, and a slidable connecting rod is arranged in the through holes 6. The lower end of the connecting rod 6 is connected to the vertical pressure plate 5, and the upper part of the connecting rod 6 forms a collar 8, and the collar 8 limits the connecting rod 6 axially.

[0024] The constant pressure head 2 is strip-shaped, and the cross section of the constant pressure head 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com