Flow augmenting method of saturated and superheated steam

A technology of superheated steam and steam flow, applied in the field of saturated and superheated steam flow correction, can solve the problems of no unified standard for saturated and superheated steam flow calculation, no application of industrial steam flow correction, cumbersome calculation process, etc., to reduce data Store volume, scale up or down, apply simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

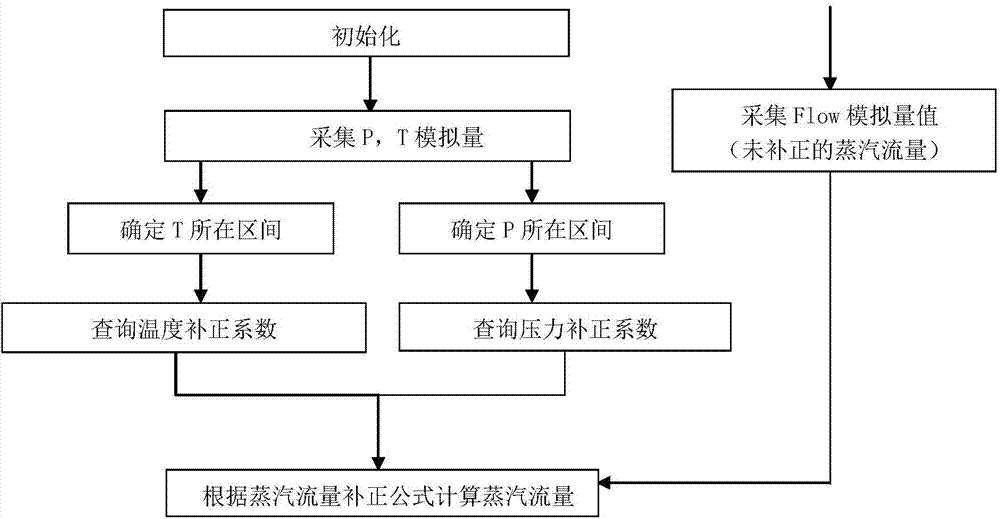

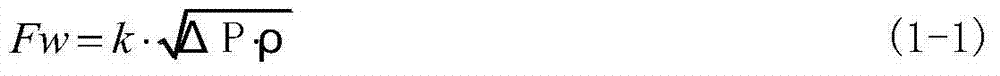

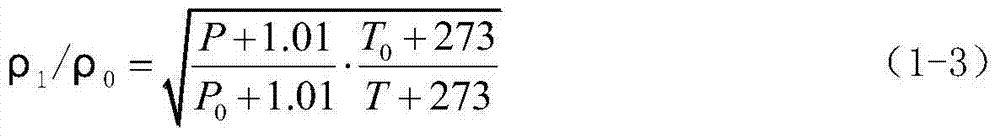

Method used

Image

Examples

Embodiment 1

[0070] The steam pressure is 0.15MPa, and the temperatures are 145°C, 162°C, 174°C, 185°C, 200°C, and 300°C. Look up Table 2 to get the pressure correction coefficient is 0.405, similarly you can get the temperature correction coefficient, see the table below:

[0071]

Embodiment 2

[0073] The steam pressure is 0.5MPa, and the temperatures are 145°C, 162°C, 174°C, 185°C, 200°C, and 300°C. Look up Table 2 to get the pressure correction coefficient is 1.00, similarly you can get the temperature correction coefficient, see the table below:

[0074]

Embodiment 3

[0076] The steam pressure is 0.75MPa, and the temperatures are 145°C, 162°C, 174°C, 185°C, 200°C, and 300°C. Look up Table 2 to get the pressure correction coefficient is 1.432, similarly you can get the temperature correction coefficient, see the table below:

[0077]

[0078] The error analysis of the above three sets of data can be obtained: the error Er=Ea / T×100%≈0.43% relative to the actual actual density value of the steam; the temperature and pressure correction accuracy of the steam flow is relatively high.

[0079] Note: The actual density value of steam is obtained by formulating IFC97 properties of water and water vapor from the International Association.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com