Leak detection processing system based on anti-seepage lining of garbage landfill pool

A technology for dealing with systems and leaks, applied in fluid tightness testing, machine/structural component testing, measuring devices, etc., can solve problems such as high work intensity, heavy workload, troubles, etc., and achieve time-consuming and inaccurate changes High efficiency, easy to use, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

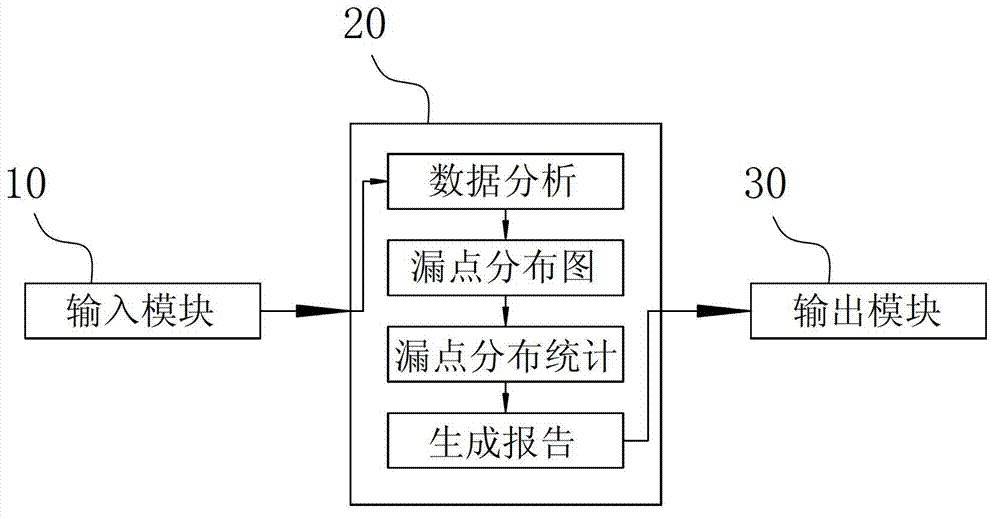

[0009] A leak detection and processing system based on the anti-seepage liner of a landfill pool, comprising an input module 10, a processing module 20 and an output module 30, the output of the input module 10 is unidirectionally connected to the input of the processing module 20, and the processing module 20 The output terminal is unidirectionally connected to the input terminal of the output module 30; the processing module 20 obtains the detection information imported by the input module 10, and performs data analysis and processing on the information to form a distribution map of leakage points, obtains statistical data of leakage and forms a report to input to the output module 30 After obtaining the processing information of the processing module 20, the output module 30 displays or prints the above information.

[0010] Its actual structural block diagram is as follows figure 1 As shown, when in use, its processing module 20 is preferably a PC; like this, by changing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com