Insulated wire pay-off stand

A technology of insulated wires and pay-off racks, applied in the direction of cable laying equipment, etc., can solve the problem of inconvenient portability of pay-off racks, and achieve the effect of time-consuming and labor-intensive changes and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

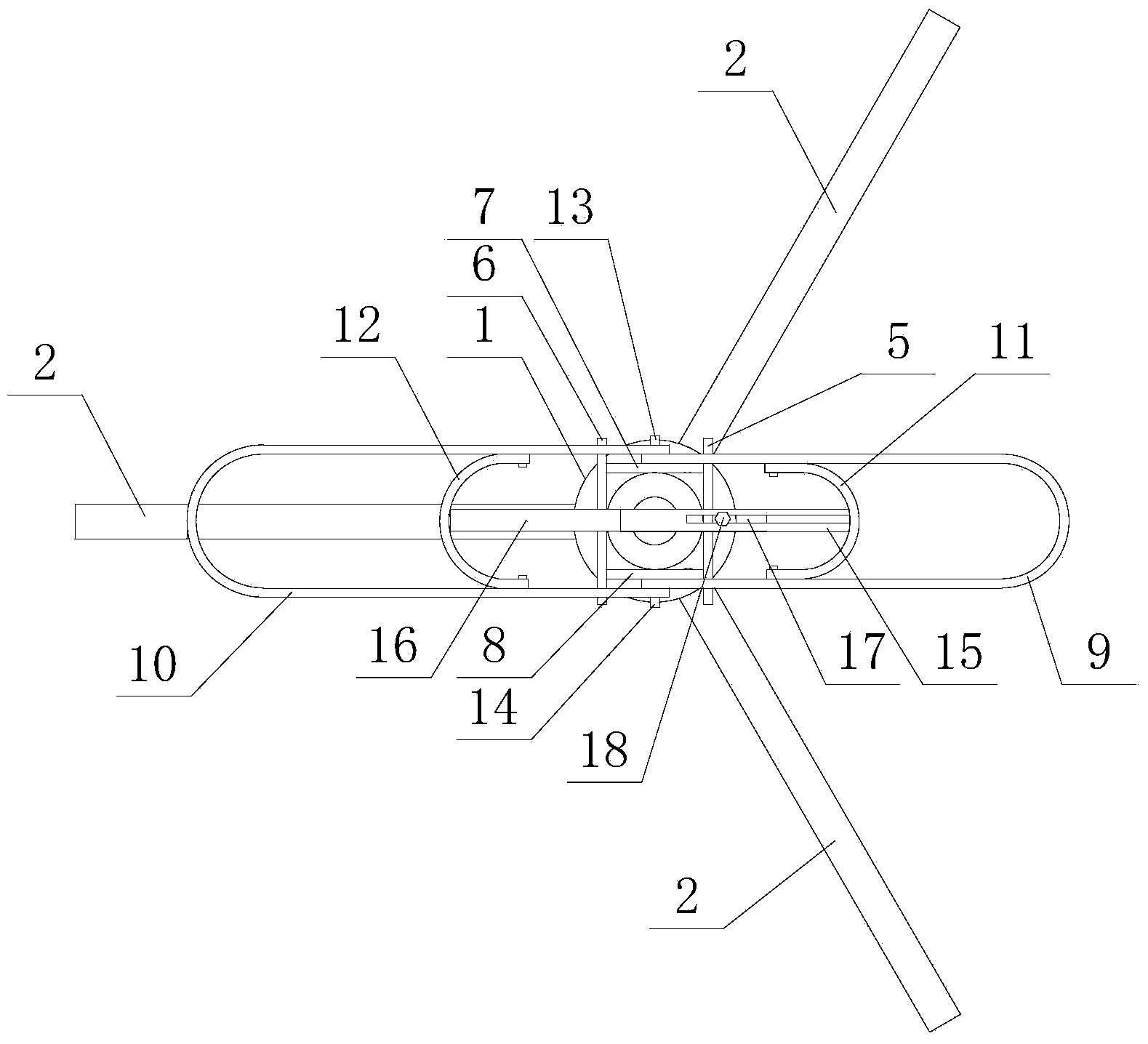

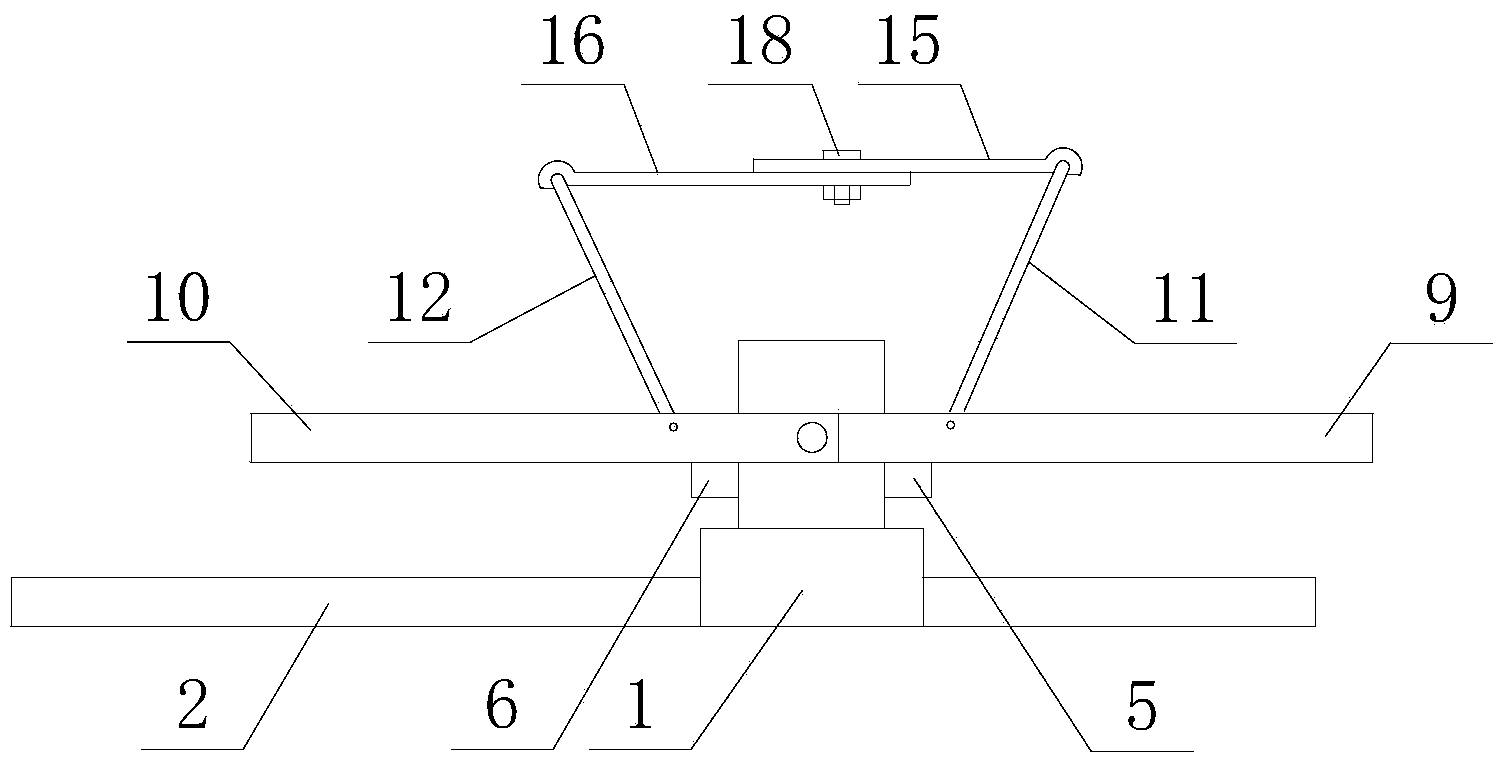

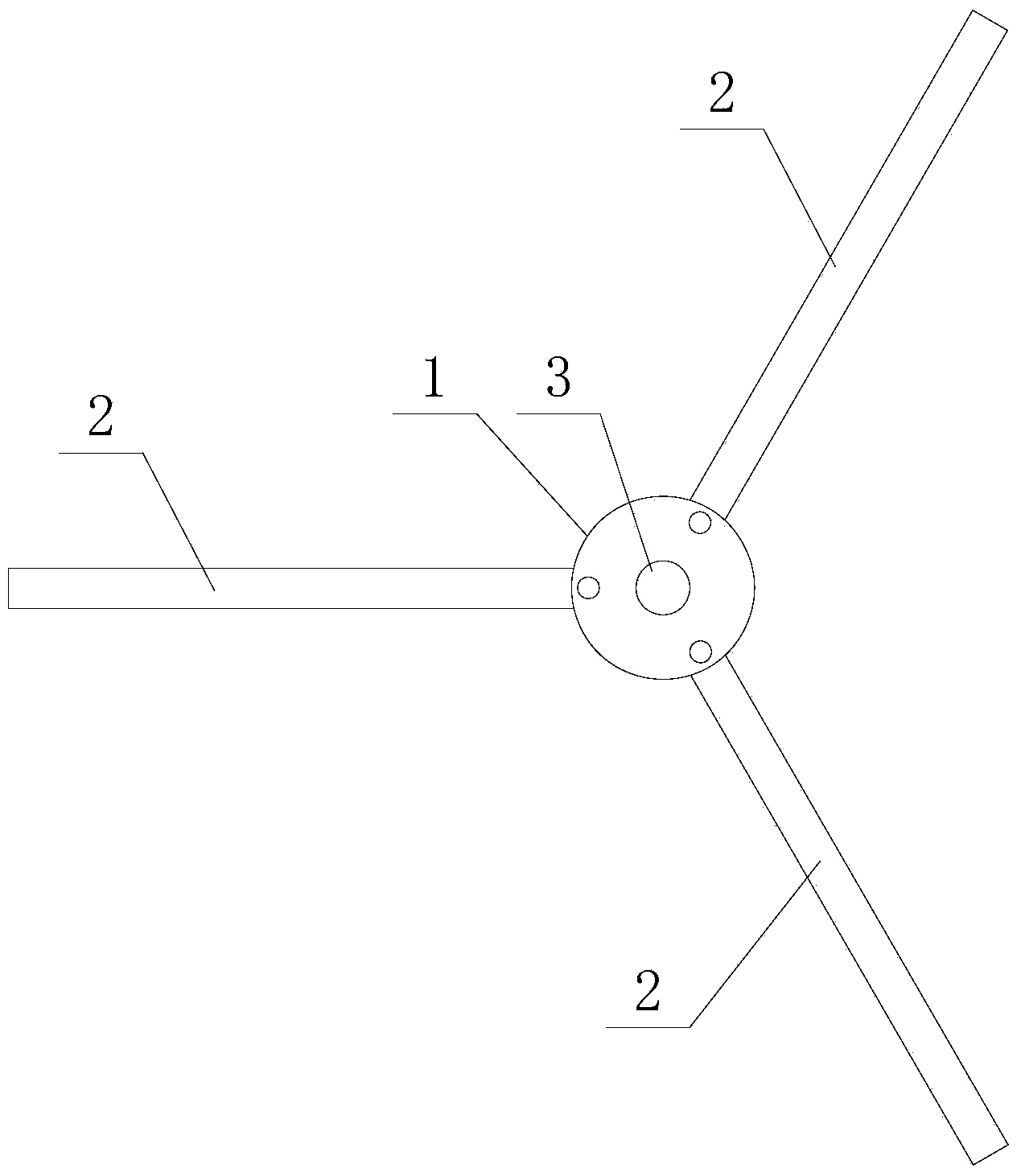

[0016] refer to figure 1 , figure 2 As shown, it is an embodiment of an insulated wire pay-off frame of the present invention, an insulated wire pay-off frame, including a folding base and a lead frame rotatably connected to the folding base;

[0017] The folding base includes a disc base 1, three legs 2 that are rotatably connected to the disc base 1, a main rotating shaft 3 fixed on the center of the disc base 1, and three turning points between the three legs 2 and the disc base 1. The distance to the center of the disc base 1 is equal;

[0018] The lead frame includes a sleeve 4 sleeved on the main shaft 3, a front main rod 5 fixedly connected to the front side wall of the sleeve 4, a rear main rod 5 fixedly connected to the rear side wall of the sleeve 4 and parallel to the front main rod 5. Rod 6, the left main rod 7 that is fixedly connected with front main rod 5 and rear main rod 6 on the left side of sleeve post 4 and is perpendicular to front main rod 5, is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com