Lifting type multi-layer clamp storage rack

A storage rack and lift-type technology, applied in the field of storage racks, can solve the problem that the partition cannot be lifted independently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

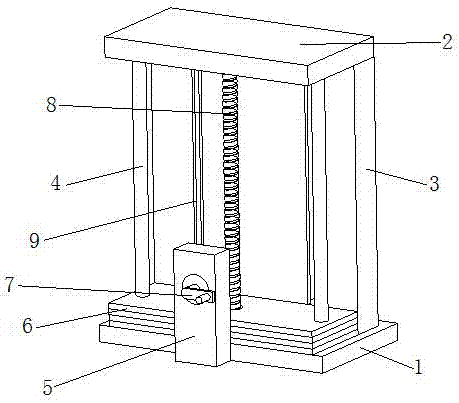

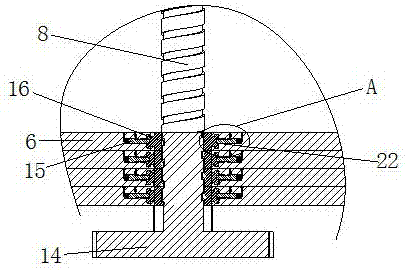

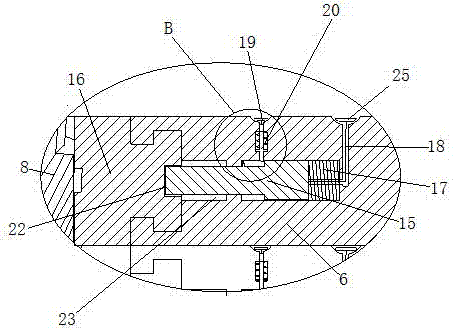

[0027] Such as Figure 1 to Figure 5 As shown, a lifting type multi-layer clamp storage frame includes a base plate 1, a top plate 2, a screw rod 8 and a plurality of swivel sleeves 16 that are threaded on the screw rod 8 and threaded therewith; the upper and lower ends of the screw rod 8 are respectively connected to The top plate 2 and the bottom plate 1 are rotationally connected; each swivel sleeve is sleeved with a partition 6; the outer peripheral surface of the swivel sleeve 16 is provided with an annular tenon, and the partition 6 is provided with an annular groove, and the annular tenon Embedded in the annular groove to limit the axial position of the partition 6; the partition 6 and the swivel sleeve 16 form a rotational connection through the cooperation of the annular tenon and the annular groove; the outer peripheral surface of the annular tenon of the swivel sleeve 16 There is a card groove 22 on the top; a guide groove 23 is arranged symmetrically about the scre...

specific Embodiment approach 2

[0041] The difference between this specific embodiment and specific embodiment 1 is that the structure of the pulling mechanism used to pull the clamping shaft 15 is different, specifically: the pulling mechanism includes a horizontal pull rod connected to the rear end surface of the clamping shaft 15, and a The horizontal via hole on the plate communicates with the rear end of the guide groove; the horizontal pull rod passes through the horizontal via hole and protrudes out of the partition, and the protruding end is connected with a pull ring. In this way, the pull rod has high strength, is not easy to be broken, and can prolong the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com