Star-wheeled transporter for construction site

A construction site and star wheel technology, applied in the field of moving vehicles, can solve problems such as misalignment and slippage, potential safety hazards, and relatively high levels of moving vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

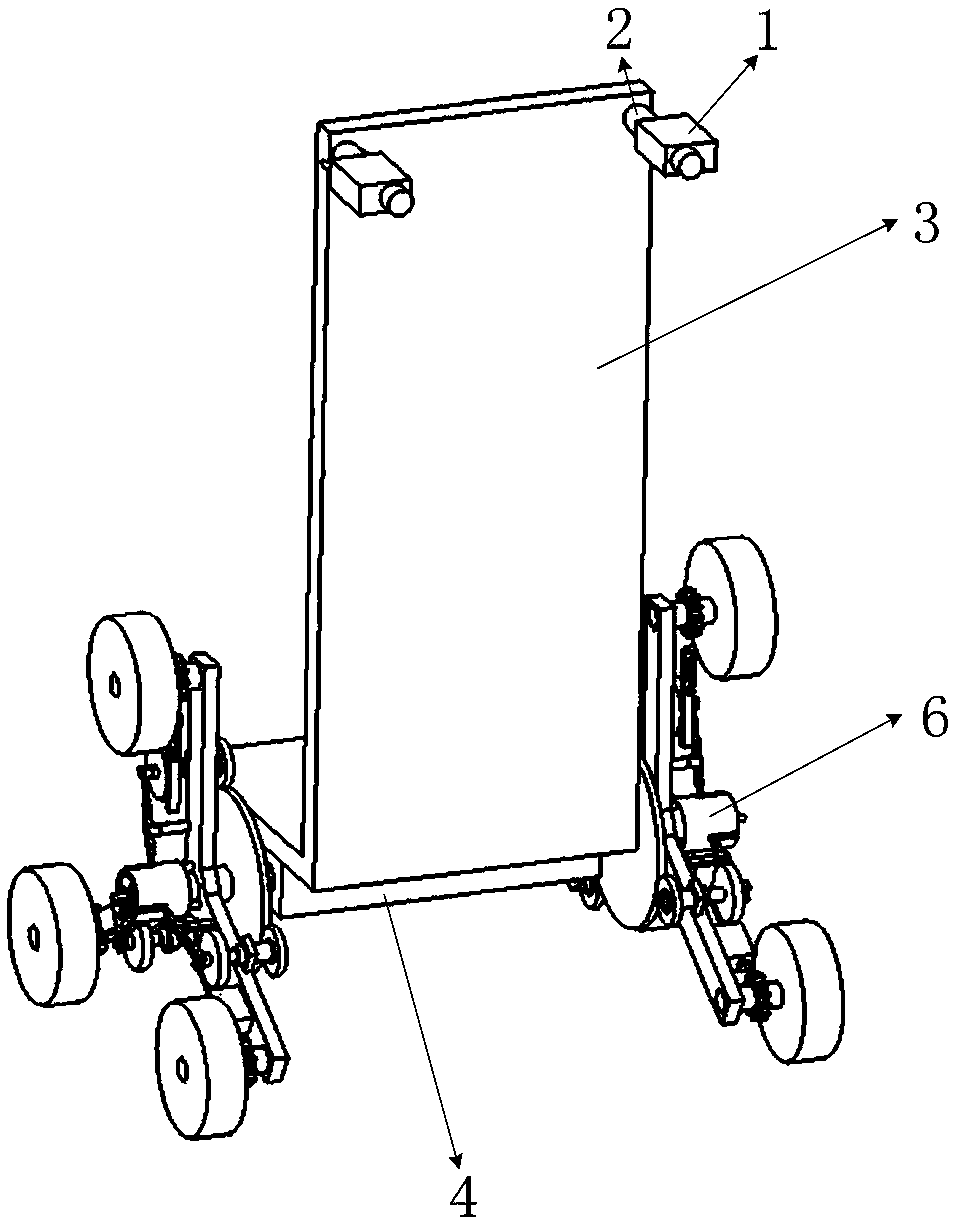

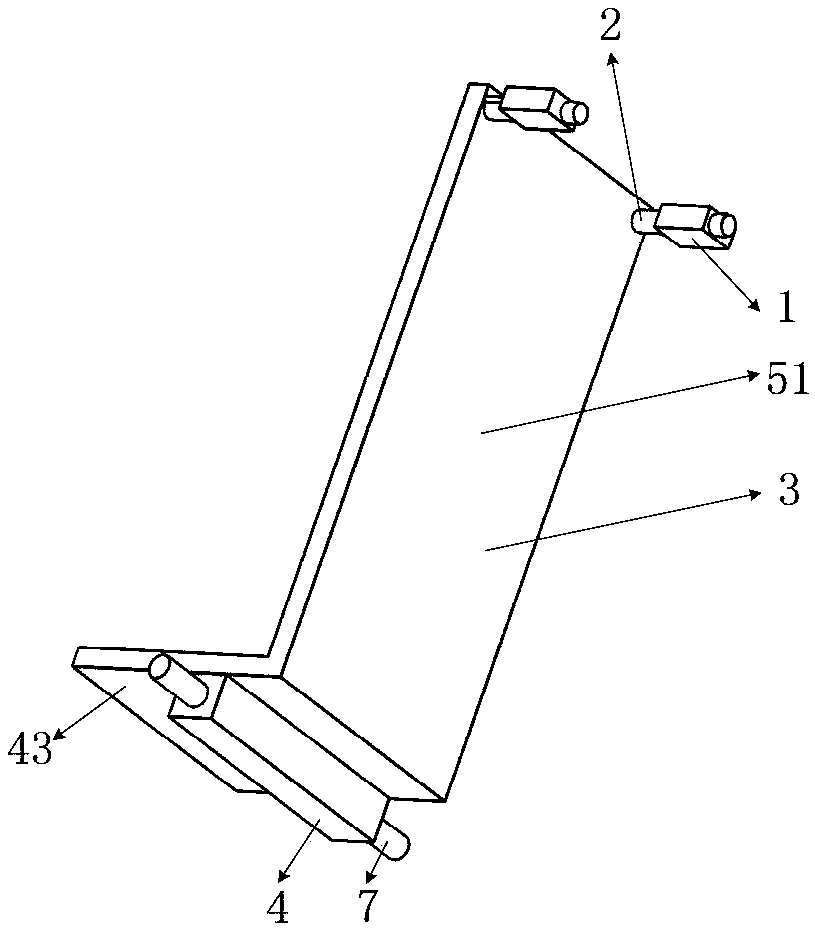

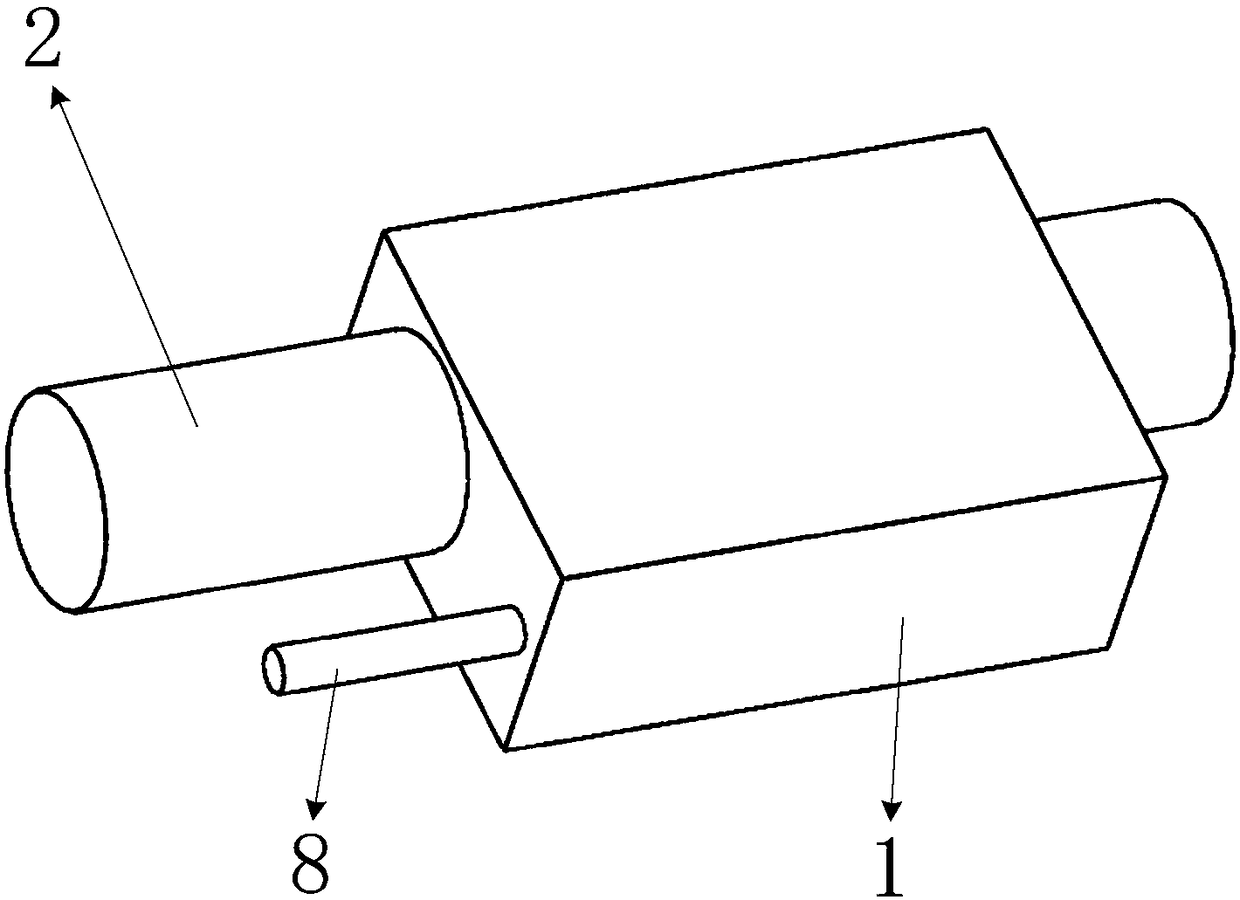

[0056] Such as figure 1 , 2 , 3, it includes hand brake 1, handle 2, L-shaped car plate 3, support block 4, star wheel mechanism 6, support shaft 7, line pipe 8, gear plate 9, as figure 2 As shown, wherein the L-shaped car plate 3 is made of a base plate 43 and a riser 51; as figure 1 , 2 As shown, a support block 4 is installed on the lower surface of the base plate 43 of the L-shaped vehicle panel 3; two handles 2 are symmetrically installed on both sides of an end of the vertical plate 51 of the L-shaped vehicle panel 3 away from the support block 4; image 3 As shown, each handle 2 is equipped with a hand brake 1; figure 2 As shown, two support shafts 7 are symmetrically fixedly installed on both sides of the support block 4; Figure 4 , 5 As shown, each support shaft 7 is equipped with a star wheel mechanism 6 at one end away from the support block 4; a toothed disc 9 is fixedly installed on the outer surface of each support shaft 7, and the tooth disc 9 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com