Steel structure beam column joint member

A beam-column joint and steel structure technology, applied in truss structures, columns, joists, etc., can solve the problems of difficult on-site welding quality assurance and high blanking accuracy requirements, so as to achieve changes in welding quality that is difficult to guarantee and component quality to be guaranteed. , the effect of less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

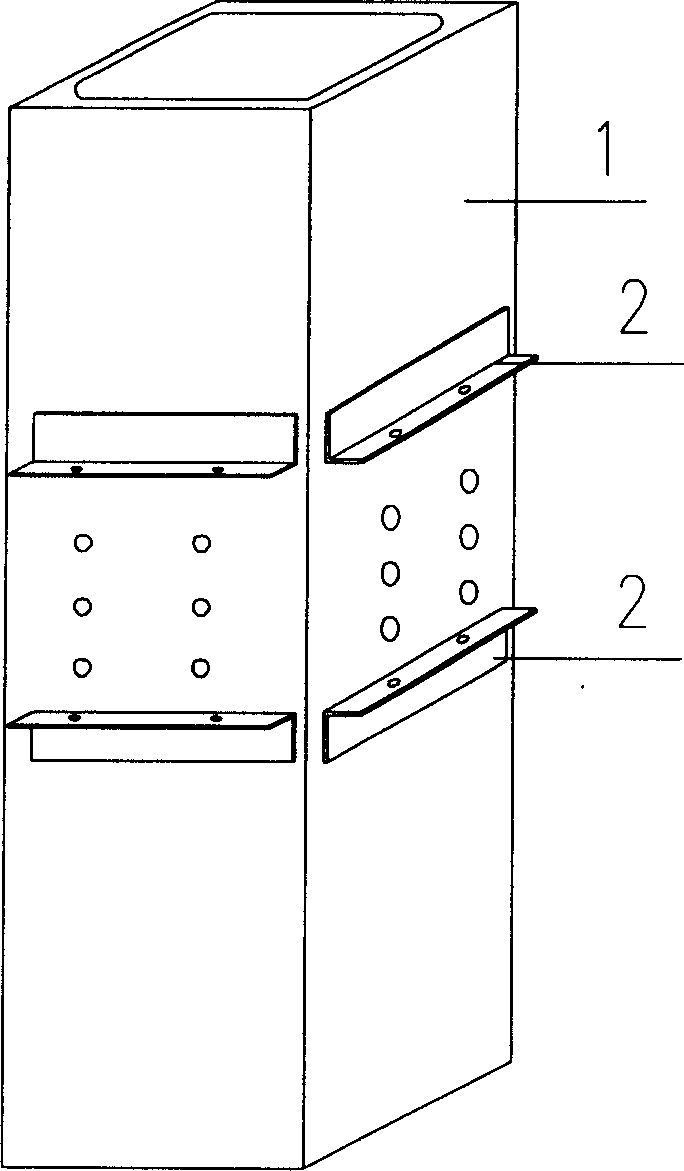

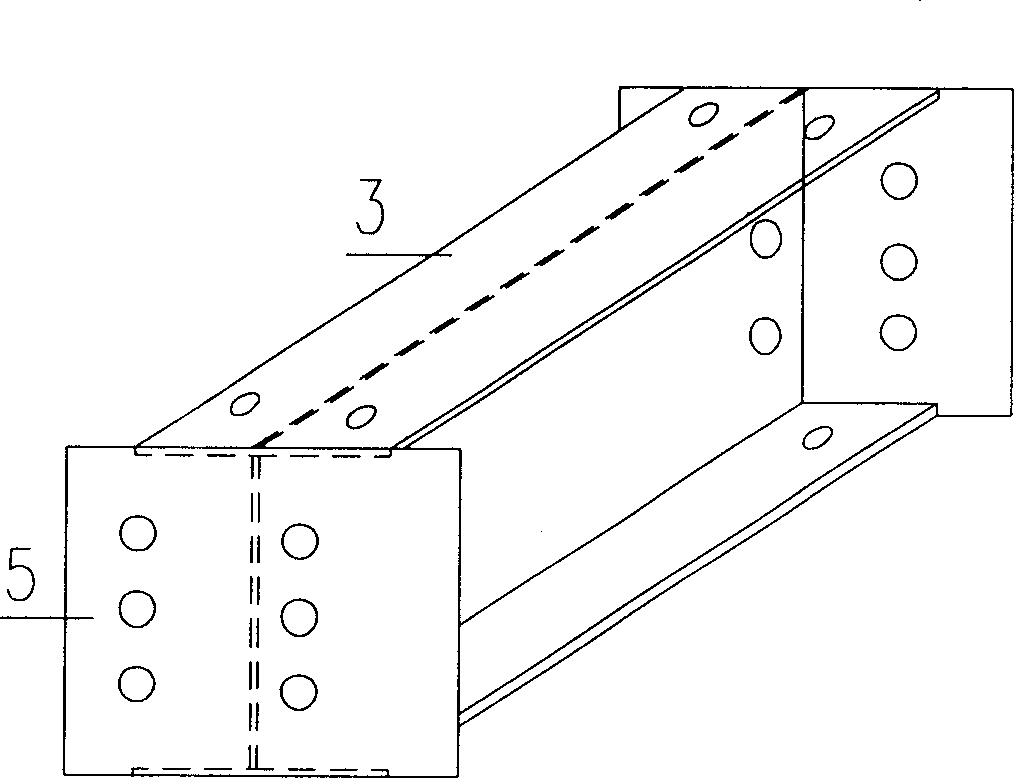

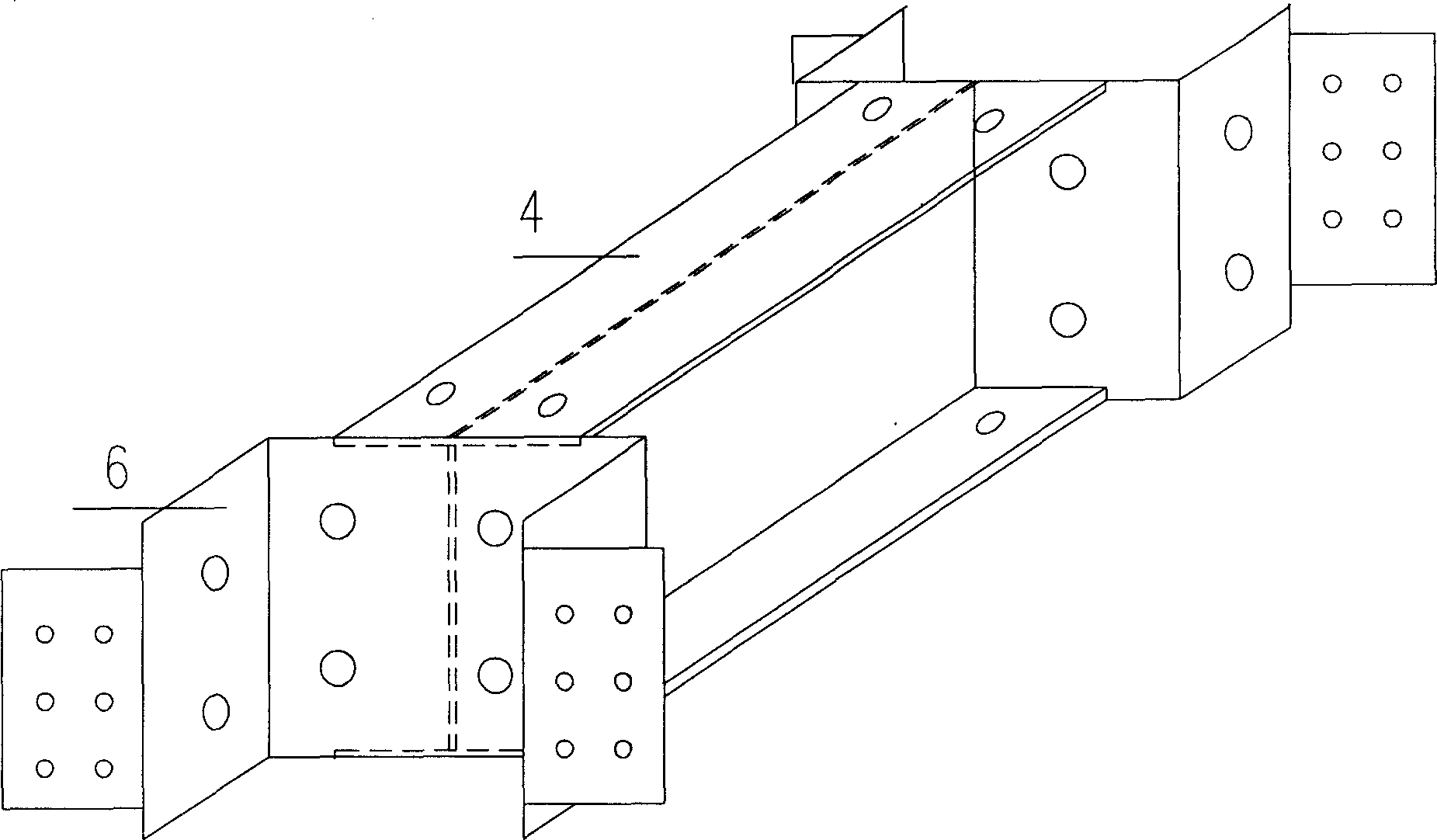

[0011] Such as figure 1 , figure 2 , image 3 As shown, the beam-column joint member of the steel structure is composed of a steel column 1 and an "I" beam. The "I" beam includes a beam 3 and a longitudinal beam 4. There are bolt holes on the side of the steel column 1. There are limit brackets 2 composed of L-shaped angle steel on both sides, and bolt holes are opened on the bracket 2; bolt holes are opened on the upper and lower flanges of the beam 3, the longitudinal beam 4, and the web plate of the beam 3, and the ends of the beam 3 The end is welded with an end plate 5, and the end plate 5 has a bolt hole, and the end of the longitudinal beam 4 is welded with a "several" shaped clamp plate 6, and the clamp plate 6 has a bolt hole.

[0012] When manufacturing in the factory, firstly, according to the design requirements, select the section of the steel column 1 and the thickness of the steel plate, and divide it into sections according to the requirements, and then weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com