Modularized array electrode of precision simulate welded joint and manufacturing method thereof

A technology of array electrodes and welded joints, applied in the field of modular array electrodes and their preparation, can solve the problems of lack of electrochemical evidence, limited understanding of electrochemical mechanisms, and inability to measure electrochemical properties locally, and achieve accurate simulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0034] Specific embodiment one: a modular array electrode that accurately simulates a welded joint. The modular array electrode includes three microelectrode modules: a base metal module, a welding heat-affected zone module, and a weld metal module. The welding heat-affected zone module is located at Between the base metal module and the weld metal module.

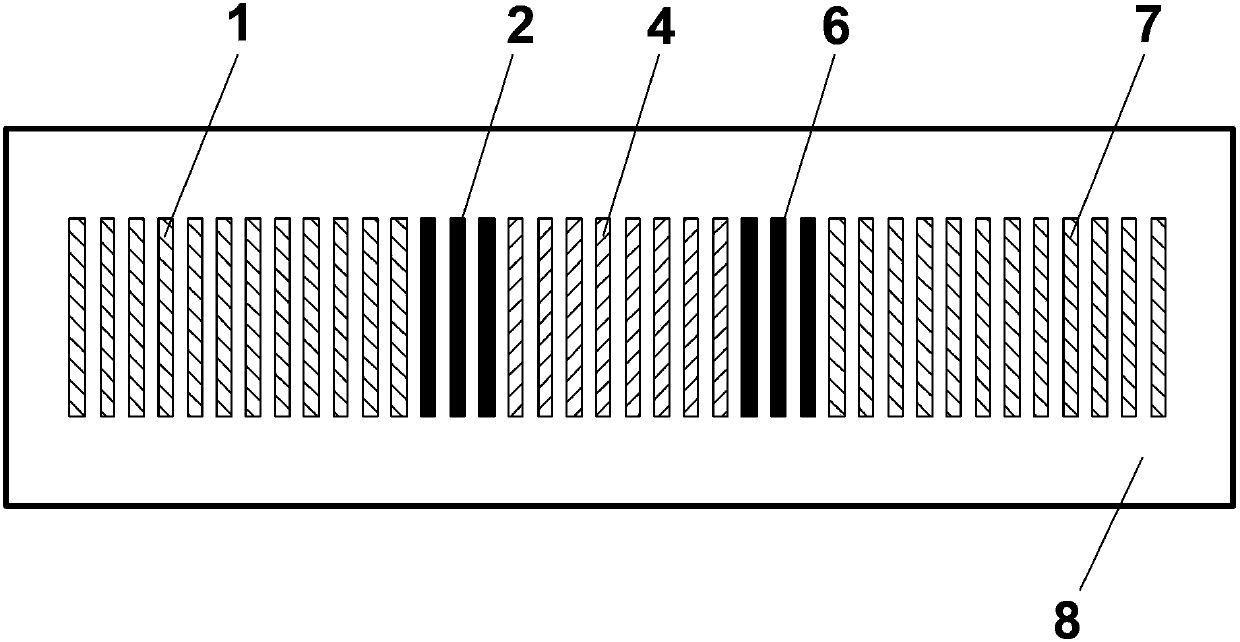

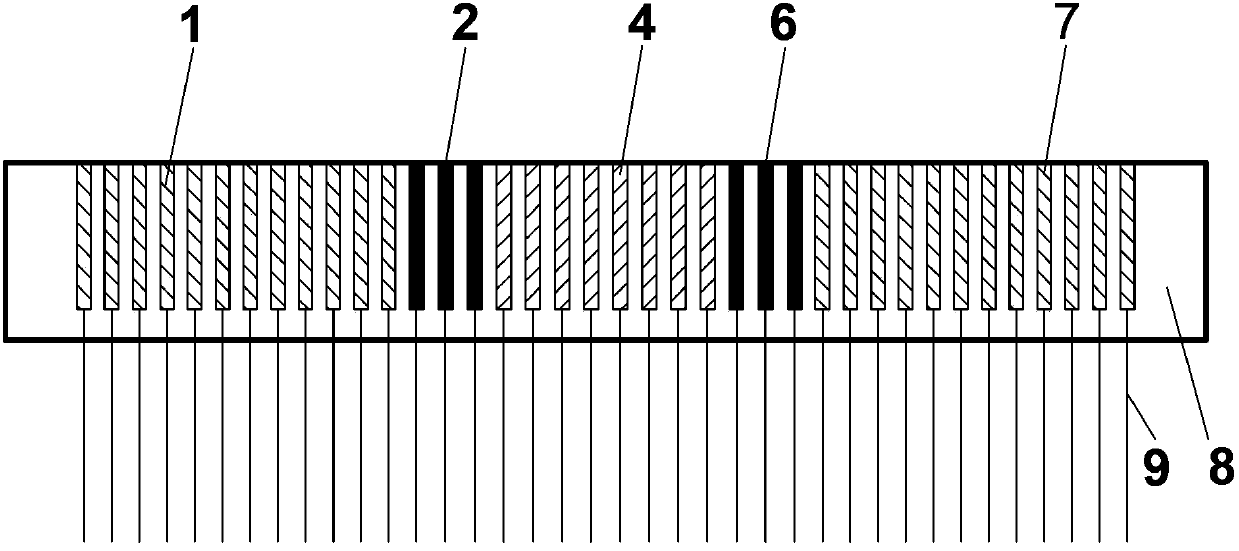

[0035] Such as figure 1 , 2 As shown, the combination sequence of the above-mentioned modular array electrodes is the first base material module 1, the first welding heat-affected zone module 2, the weld metal module 4, the second welding heat-affected zone module 6, and the second base metal module 7 , and arranged symmetrically with the weld metal module 4 as the center.

[0036] The preparation steps of the above-mentioned modular array electrode are as follows:

[0037] (1) On the welded joint entity, cut and sample the base metal and weld metal respectively along the direction of the weld and perpendicular to the j...

specific Embodiment 2

[0048] Specific embodiment two: a modular array electrode for accurately simulating welded joints. The modular array electrode includes three microelectrode modules: a base metal module, a welding heat-affected zone module and a weld metal module. The welding heat-affected zone module is located in Between the base metal module and the weld metal module. The welding heat-affected zone module is a combination of the overheated zone module, the normalizing zone module, and the partial phase change zone module.

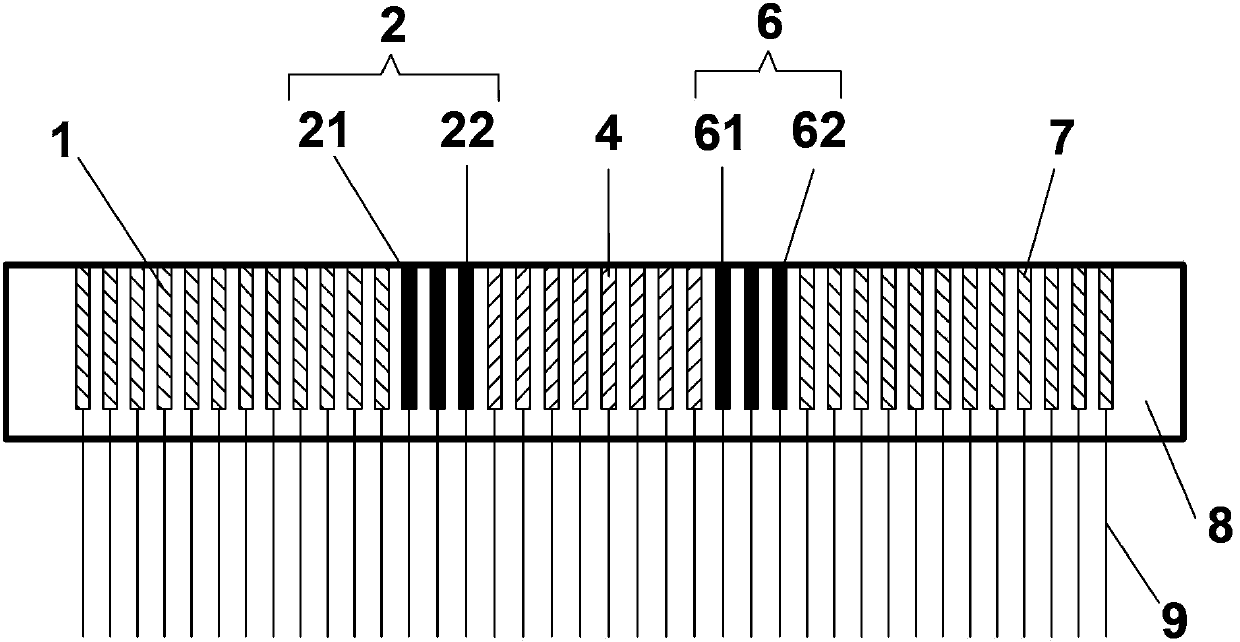

[0049] Such as image 3 As shown, the combination sequence of the above-mentioned modular array electrodes is the first base material module 1, the first welding heat-affected zone module 2, the weld metal module 4, the second welding heat-affected zone module 6, and the second base metal module 7 , and arranged symmetrically with the weld metal module 4 as the center. Among them, the first welding heat-affected zone module 2 includes the first partial phase change zon...

specific Embodiment 3

[0054] Specific embodiment three: a modular array electrode that accurately simulates a welded joint, the modular array electrode includes three microelectrode modules: a base metal module, a welding heat-affected zone module, and a weld metal module. The welding heat-affected zone module is located in Between the base metal module and the weld metal module. The welding heat-affected zone module is a combination of three types: an overheated zone module, a normalizing zone module, and a partial phase change zone module.

[0055] Such as Figure 4 As shown, the combination sequence of the above-mentioned modular array electrodes is the first base material module 1, the first welding heat-affected zone module 2, the weld metal module 4, the second welding heat-affected zone module 6, and the second base metal module 7 , and arranged symmetrically with the weld metal module 4 as the center. Among them, the first welding heat-affected zone module 2 includes the first partial pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com