Jet flow angle velocity transducer and method for making same

A speed sensor, jet angle technology, applied in the direction of linear/angular velocity measurement, velocity/acceleration/shock measurement, instrument, etc., can solve the problem of large volume, achieve the effect of small volume, compact structure, and avoid wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

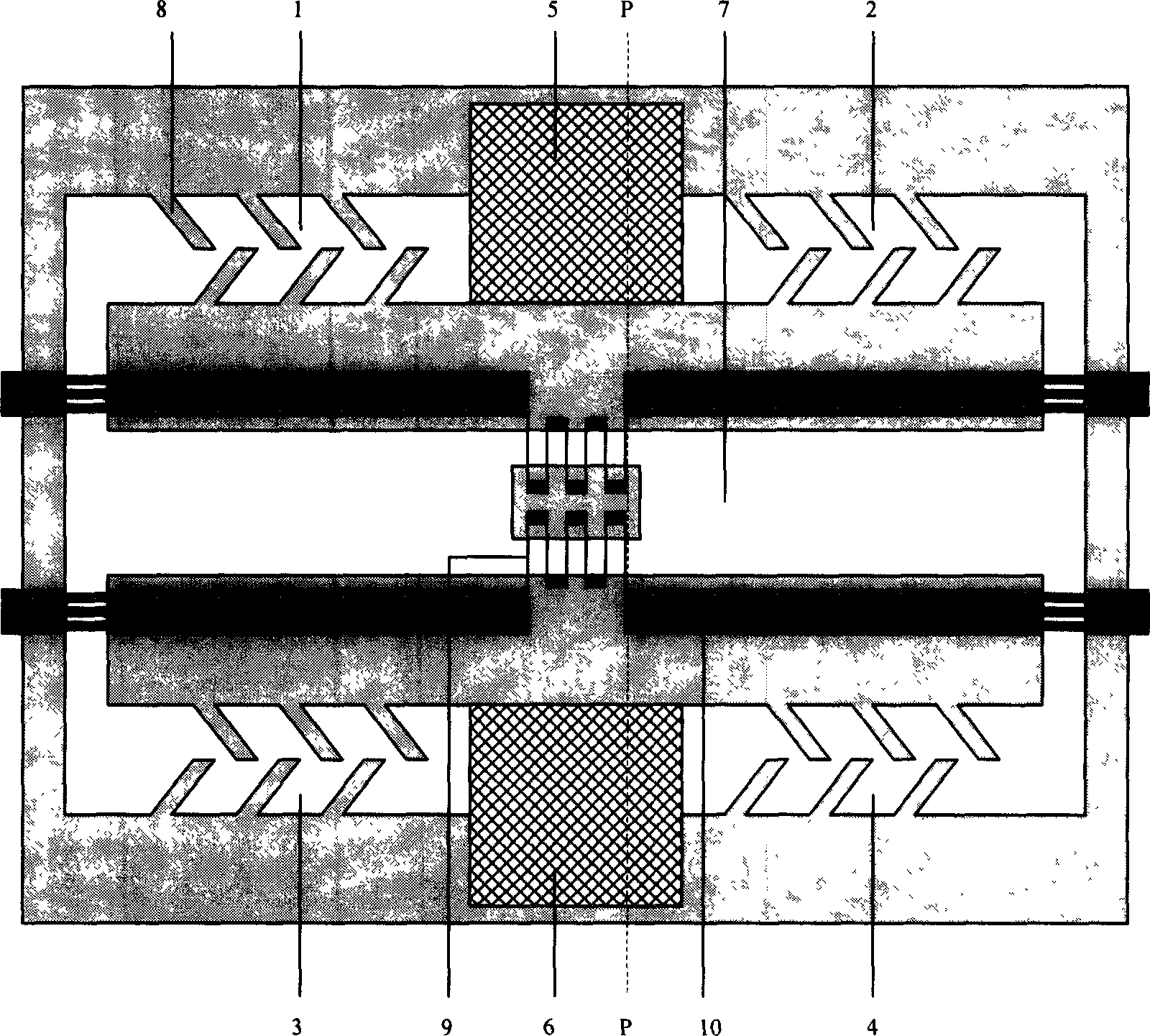

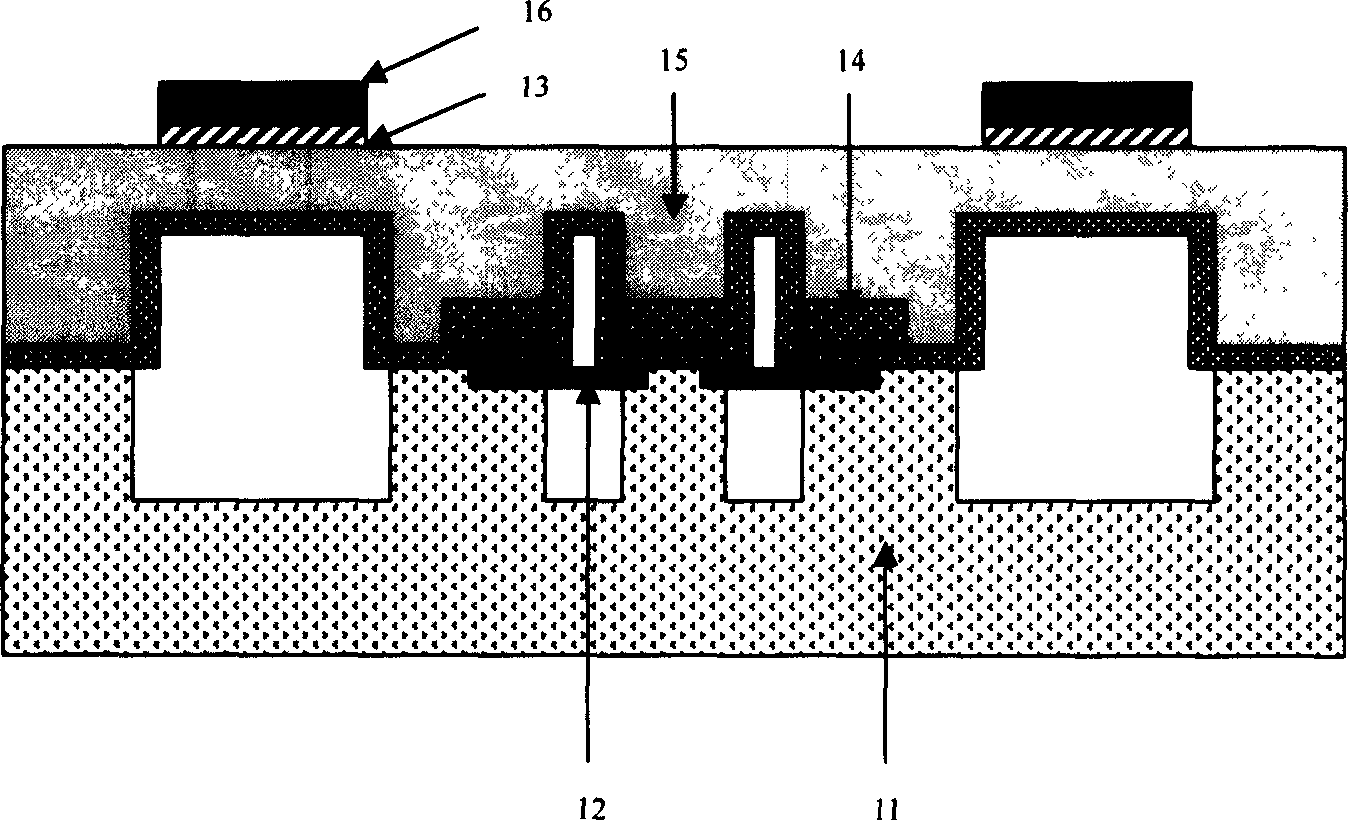

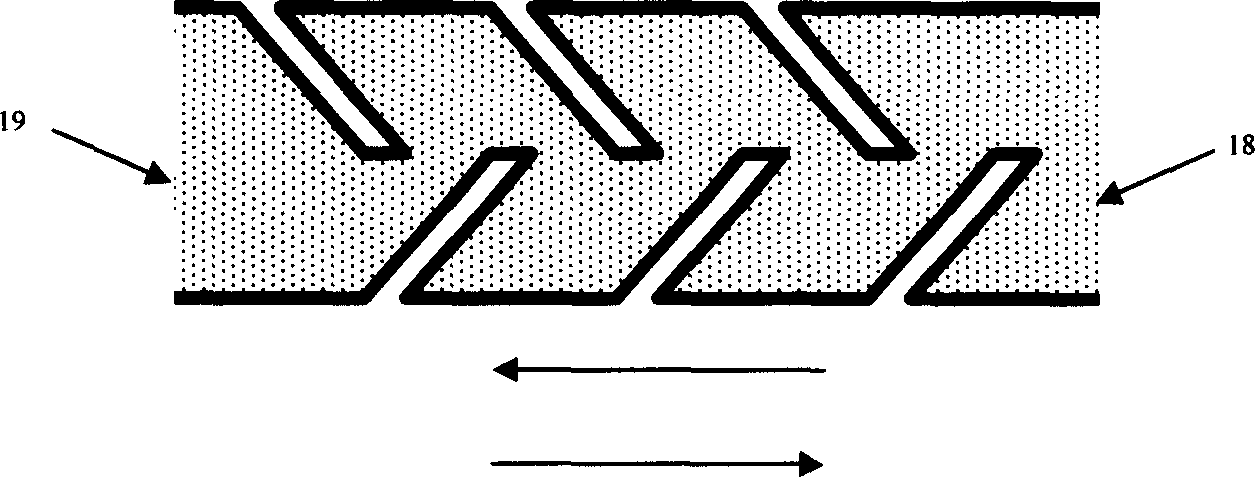

[0032] figure 1 It is a structural schematic diagram of the mace jet angular velocity sensor, figure 2 for figure 1 Cross-sectional view of the P-P plane. It can be seen from the figure that the mace jet angular velocity sensor is composed of four rectifying cavities 1, 2, 3, 4, two vibrating cavities 5, 6, and one detection cavity 7. Two thermistor wires 9 are placed symmetrically in the detection chamber 7 , and the two thermistor wires 9 are connected to a Wheatstone bridge through lead wires 10 . The separation wall below the lead wire 10 not only supports the lead wire, but also isolates the detection chamber 7 from the vibration chambers 5, 6 and the rectification chambers 1, 2, 3, and 4. The four rectification chambers are respectively arranged on both sides of the two vibration chambers, and the detection chamber 7 is located between the two vibrating chambers 5 and 6, each rectifying chamber is a mace fluid diode, and the mace fluid diode is composed of six mace-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com