Multi-pipe type high-temperature electromagnetic floating-bed dust remover

A dust collector and floating bed technology, which is used in chemical instruments and methods, dispersed particle separation, and dispersed particle filtration, etc. High water consumption and other problems, to achieve the effect of convenient filter material update, no gas short circuit, and taking into account the filter pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

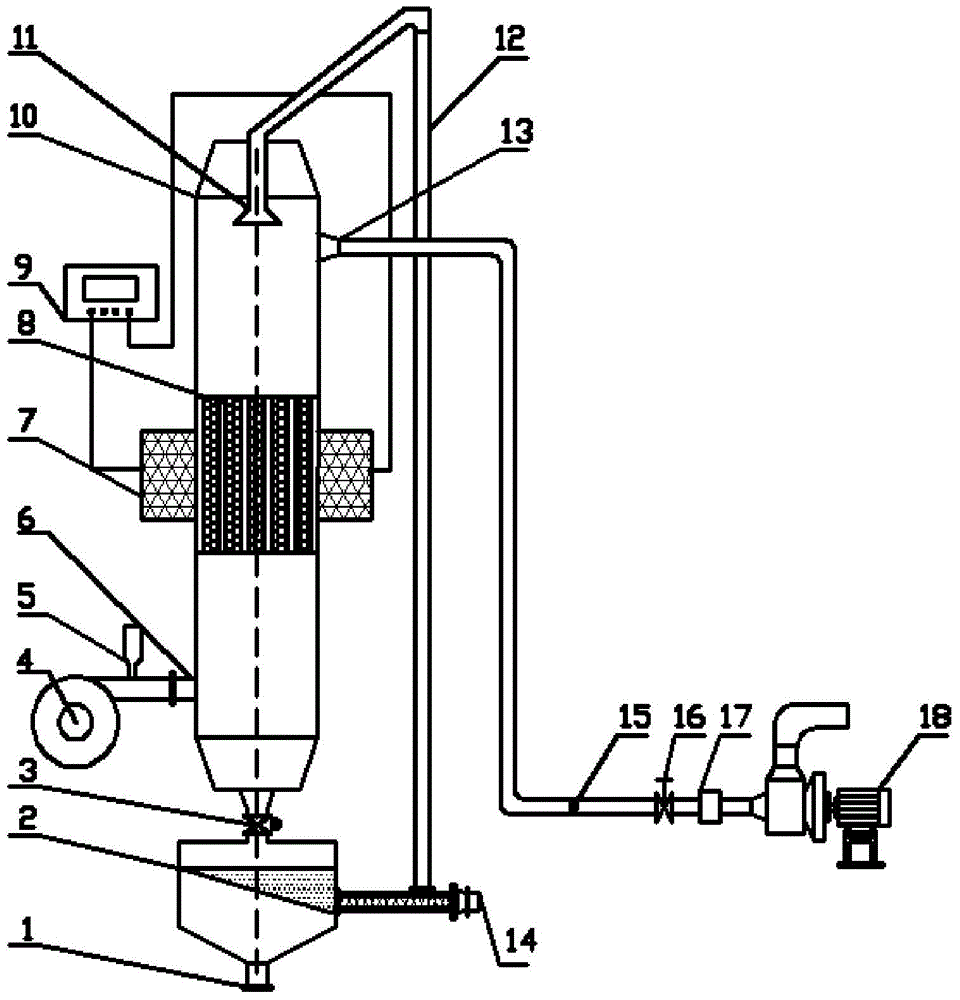

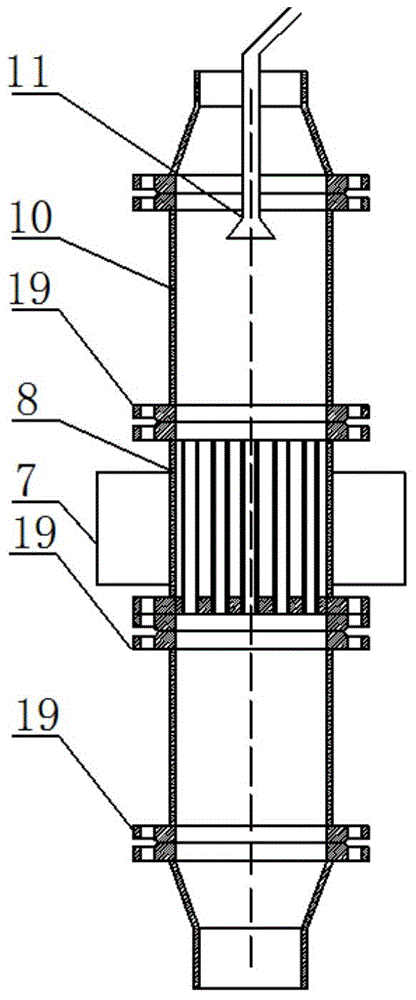

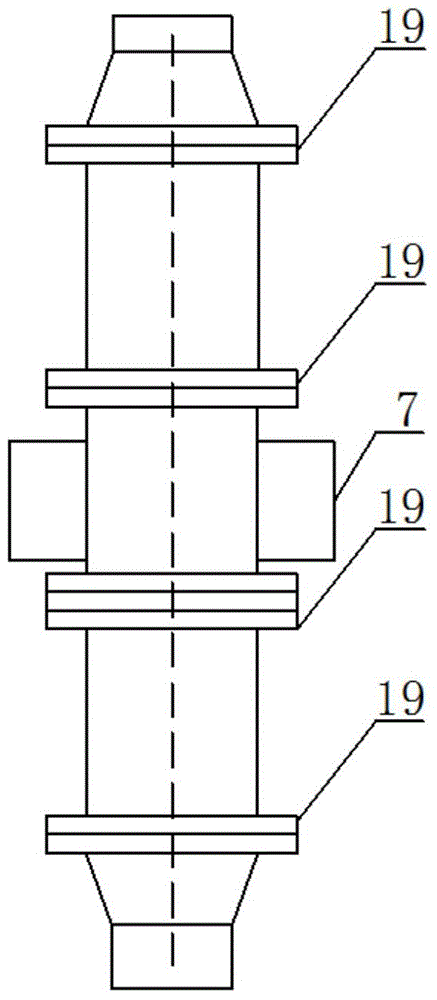

[0034] Such as figure 1 and 2As shown, the present invention is a multi-tube type high-temperature electromagnetic floating bed dust collector. The dust collector includes a dust collector main body 10. The dust collector main body 10 includes three sections of upper, middle and lower cylinders, and the three sections of cylinders pass through flanges 19 Connected through the flange connection hole 20, the middle cylinder is provided with a multi-tubular floating bed 8 inside, and an electromagnetic coil 7 is arranged on the outside, and the electromagnetic coil 7 is connected to a DC stabilized voltage power supply 9, and the multi-tubular floating bed 8 includes 17 A round tube filled with 4mm high magnetic particles, the side wall of the lower cylinder is provided with an air inlet 6, the air inlet 6 is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com