Circle application of waste condensate water during pulping with ammonium sulfite method

A technology of pulping process and condensed water, which is applied in the recycling field of waste liquid in the ammonium pulping process, can solve the problems of waste of resources, environmental pollution, etc., improve production efficiency, increase porosity and air permeability, and relieve hardening degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

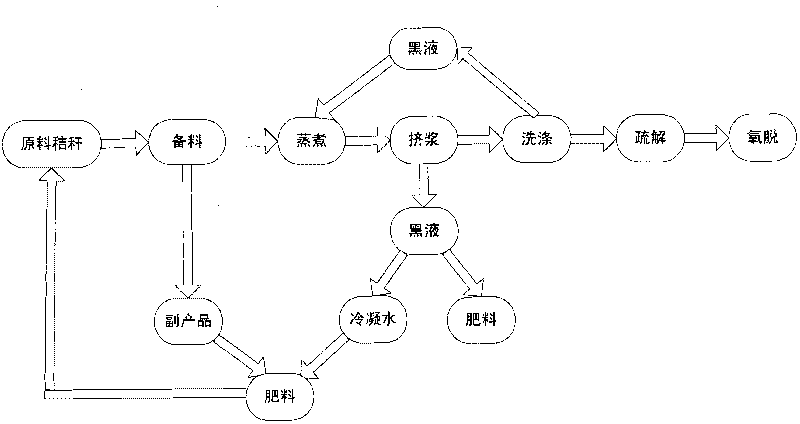

[0101] combine figure 1 Specifically explain the recycling of waste liquid or waste in the process of ammonium ammonium pulping, cut off wheat straw, dedust and remove grain, etc., to obtain wheat straw and by-product wheat bran for pulping; after cooking with ammonium sulfite solution After that, thick black liquor is produced by pulping, and the thick black liquor is concentrated to make fertilizer and condensed water; the thin black liquor obtained by washing the products after pulping can be recycled to cooking.

[0102] Add 2000kg of waste wheat bran produced in the pulping process into 1000kg of waste wheat bran, which contains 2000ppm of nitrogen and a temperature of 60°C of heavy pollution condensed water and 6kg of bran, and stirs and mixes evenly, wherein the water content is 70%. The mass ratio of carbon and nitrogen in the mixture is C: N = 25: 1, and the pH is 9.5. After mixing, the strip stack fermentation method is used for natural aerobic fermentation. The temp...

Embodiment 2

[0104] Add 1000kg of rice straw to 3000kg of pulping process produced by our company with nitrogen content of 2500ppm and temperature of 70 ℃ heavy pollution condensed water, then add 5kg of bran, stir and mix evenly, the water content is 65%, and the carbon in the mixture The mass ratio to nitrogen is C:N=18:1, and the pH is 10.0. After mixing, the strip-stack fermentation method is used for natural aerobic fermentation. The temperature is detected during the fermentation process. The temperature in the fermentation process rises gradually. After 14 days at 55-60°C, it begins to drop. The temperature drops to 35°C and the fermentation process ends, and its pH is 6.5. The obtained product organic compost contains 35.25g of organic matter, 10.85g of humic acid, and total potassium content per 100g The total phosphorus content is 1.63g, the total phosphorus content is 0.84g, and the total nitrogen content is 1.59g; the ventilation space is 48.8%, the total porosity is 46.64, the ...

Embodiment 3

[0106] (1) material preparation

[0107] Prepare the wheat straw straw to obtain the processed wheat straw straw and waste wheat bran;

[0108] (2) Cooking and pulping

[0109] Add the cooking agent ammonium sulfite to the treated wheat straw obtained in the previous step, wherein the amount of ammonium sulfite is 9% of the absolute dry raw material, the liquid ratio is 1:2, and steam is added for heating, and the temperature is raised to 100 Keep warm for 20 minutes at ℃, carry out small degassing, continue to heat up to 165 ℃, keep warm for 60 minutes, and obtain a high-hardness pulp with a concentration of 8% and a hardness of 16 potassium permanganate values;

[0110] (3) Post-treatment of high hardness pulp to obtain dilute black liquor

[0111] Enter the high-hardness pulp obtained in the previous step from the entrance of the squeezer, squeeze out the black liquor, wash the pulp after extruding the black liquor, and combine the extruded black liquor and the black liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com