Method for repairing contaminated soil in coal-to-gas plant by adopting microbe-plant combined way

A technology for joint remediation and contaminated soil, applied in the field of soil remediation of polluted sites, can solve the problems of less consideration for the restoration of soil environmental ecological function diversity, less types of organic-heavy metal pollutants, and poor environmental friendliness of chemical eluents, etc. Achieve high environmental friendliness, increased density, easy management and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with example the present invention is further described. It should be understood that the described examples are only for illustration and not limitation of the invention.

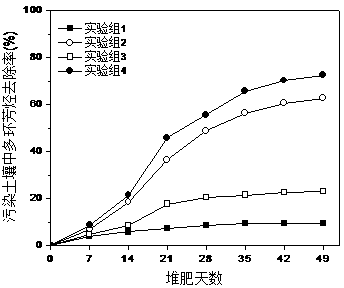

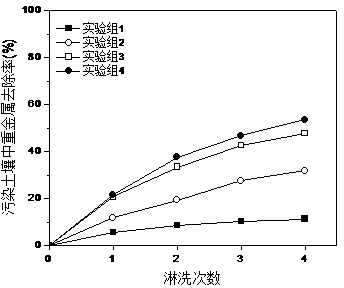

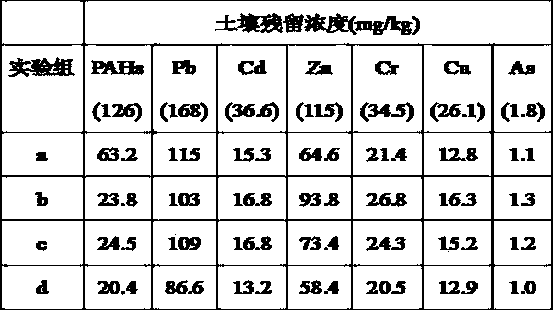

[0034] The test soil was collected from a polluted site of a closed coal-to-gas plant in Nanchang City. The soil samples were air-dried, and impurities such as stones and branches were sorted out, passed through a 10-mesh sieve, and mixed well for later use. The basic physical and chemical properties of the soil are pH 7.3, organic matter content 35.1 g / kg, total nitrogen 0.65 g / kg, available nitrogen 38.3 mg / kg, total phosphorus 116 mg / kg, available phosphorus 25.6 mg / kg. The total PAH content in the soil was 578 mg / kg. The contents of Pb, Cd, Zn, Cr, Cu and As were 365, 57.4, 276, 75.2, 44.3 and 4.6 mg / kg, respectively. The contents of total aerobic bacteria, total anaerobic bacteria and PAH degrading bacteria in the soil were 5.15×10 6 , 7.21×10 4 and 3.36×10 5 CFU / g. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com