Oily food raw materials for coating frozen snacks

A snack and coating technology, applied in frozen desserts, edible oil/fat, application, etc., can solve the problems of difficult weight per unit area, poor hardening, insufficient effect, etc., to achieve good operability, maintenance of commercial value, and inhibition of cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

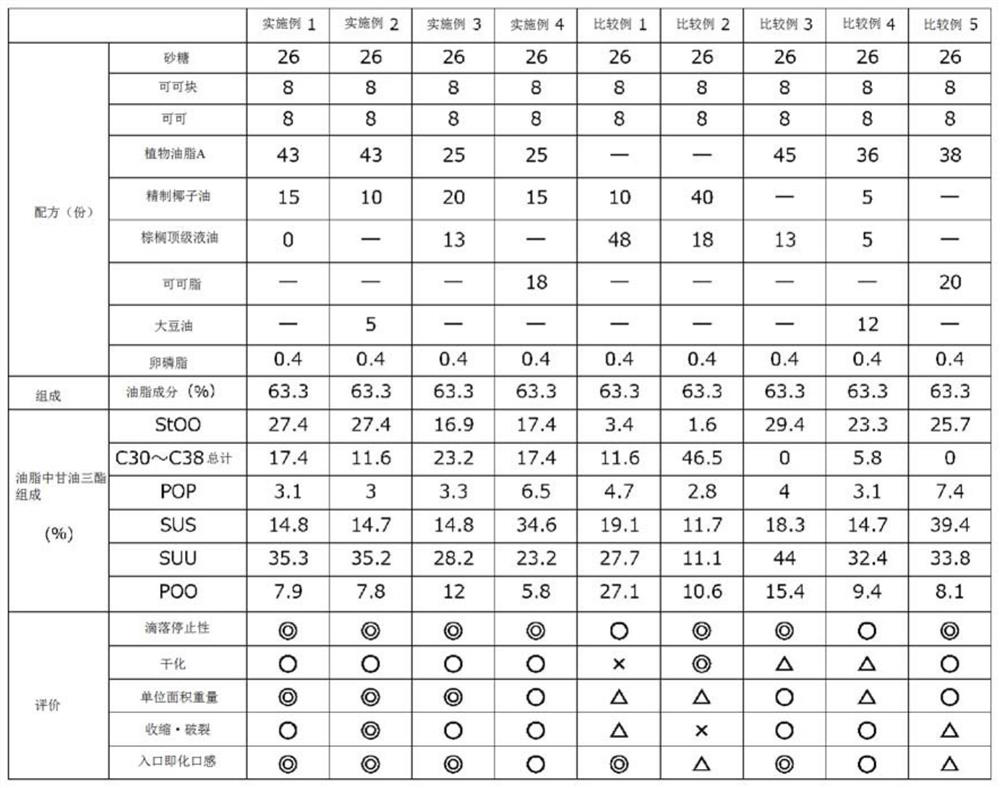

[0083] Examples and comparative examples are described below to describe the present invention in more detail. In addition, unless otherwise specified, "%" and "part" in an example mean a weight basis.

[0084] (Preparation of oily food raw materials (chocolate))

[0085] According to the raw material formulation shown in Table 1, rolling and conching were carried out by conventional methods to prepare chocolates respectively. In addition, the particle size was adjusted to 18 micrometers, and the viscosity was adjusted to 300 cp (40 degreeC, B type viscometer, No. 2 rotor, 30 rpm). In addition, "vegetable oil A" in the table is an oil and fat having a StOO content of about 40%. Fractionation of transesterified fats and oils obtained by 1,3-specific lipase using high oleic sunflower oil and stearic acid as raw materials low melting point.

[0086] (ice coating test)

[0087] Chocolates were heated and melted, adjusted to 40° C., and a coating test was implemented using a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com