Radiating material and preparation method of radiating material

A heat dissipation material and resin technology, applied in electrolytic coating, electrophoretic coating, epoxy resin coating, etc., can solve the problem that surface treatment technology cannot improve heat dissipation performance, and achieve the effect of improving heat dissipation effect, easy appearance, and no dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

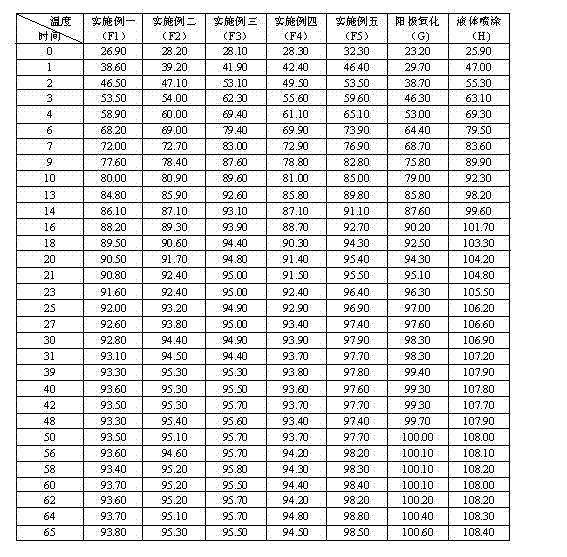

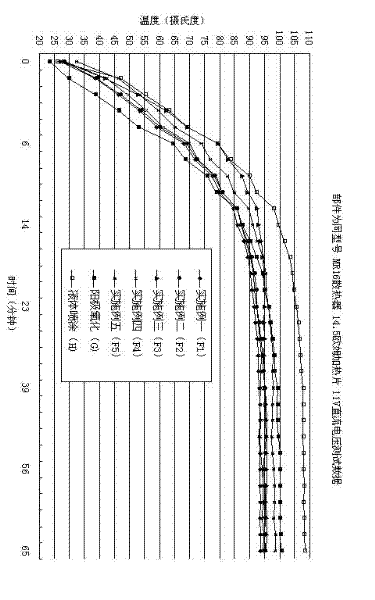

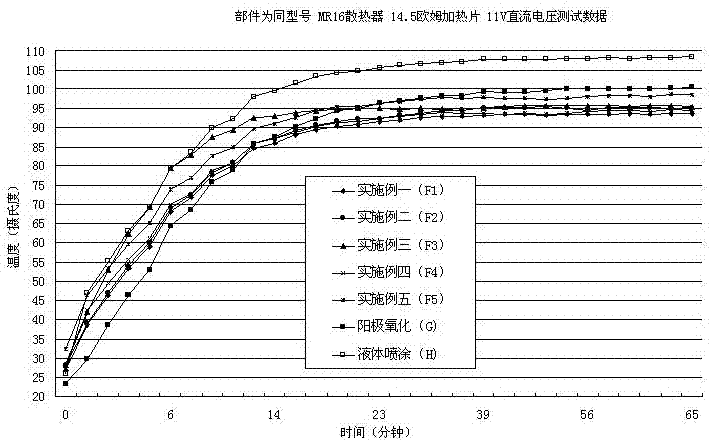

Examples

Embodiment 1

[0031] Weigh 1Kg of anionic acrylic resin aqueous dispersion (solid content 50%), slowly add 3Kg of pure water while stirring (the conductivity of pure water is less than 8us / cm) (called A); weigh Al 2 o 3 , SiO 2 , MgO in proportion (the ratio of the amount of substances is 20:1:3) mixed and sintered and crushed into 165g of powder with a particle size of 1~3um (called B1), and silicon carbide with a particle size of 1~3um (content greater than 98%) (called B2) 125g, after mixing, wash with pure water until the conductivity is less than 100us / cm (called D); add D to 1Kg of pure water (conductivity less than 8us / cm), while stirring Add A, grind for 30 minutes and put it into the electrophoresis tank for circulation; the extruded aluminum alloy radiator (called E) will be the anode after the pretreatment processes such as degreasing, alkali etching, and light emission, and the stainless steel plate will be the cathode. Apply a DC voltage of 100V for 60 seconds; wash with pure...

Embodiment 2

[0033] Weigh 1 Kg of cationic acrylic resin water-based dispersion (solid content 50%), slowly add 3Kg of pure water while stirring (the conductivity of pure water is less than 8us / cm) (called A); weigh Al 2 o 3 , SiO 2, MgO in proportion (the ratio of the amount of substances is 20:1:3) mixed and sintered and crushed into 165g of powder with a particle size of 1~3um (called B1), and silicon carbide with a particle size of 1~3um (content greater than 98%) (called B2) 125g, after mixing, wash with pure water until the conductivity is less than 100us / cm (called D); add D to 1Kg of pure water (conductivity less than 8us / cm), while stirring Add A, grind for 30 minutes, and put it into the electrophoresis tank for circulation; the extruded aluminum alloy radiator (called E) will be the cathode after degreasing, alkali etching, light emitting and other pretreatment processes, and the stainless steel plate will be the anode. Apply a 60V DC voltage for 45 seconds; wash with pure wat...

Embodiment 3

[0035] Weigh 5Kg of cationic epoxy resin aqueous dispersion (solid content 20%) (called A); weigh Al 2 o 3 , SiO 2 , MgO in proportion (the ratio of the amount of substances is 20:1:3), mixed, sintered and pulverized into 350 grams of powder (called B1) with a particle size of 1~3um, and silicon carbide with a particle size of 3~5um (content greater than 98%) (called B2) 300 grams, after mixing, wash with pure water until the conductivity is less than 100us / cm (called D); add D to 5Kg of pure water (conductivity less than 8us / cm), and Add A while stirring, and put it into the electrophoresis tank for circulation after grinding for 30 minutes; the extruded aluminum alloy radiator (called E) is used as the cathode after degreasing, alkali etching, light emitting and other pretreatment processes, and the stainless steel plate is Apply 120V DC voltage to the anode for 60 seconds; wash it with pure water and put it in an oven to bake, heat up to 180 degrees Celsius, keep it warm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com