Dead-corner-free eccentric variable-blade-length stirring device

A stirring device, eccentric technology, applied in the field of non-dead angle eccentric variable blade length stirring device, can solve the problems of stirring blade damage, single working principle, influence, etc., and achieve the effect of no dead angle and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

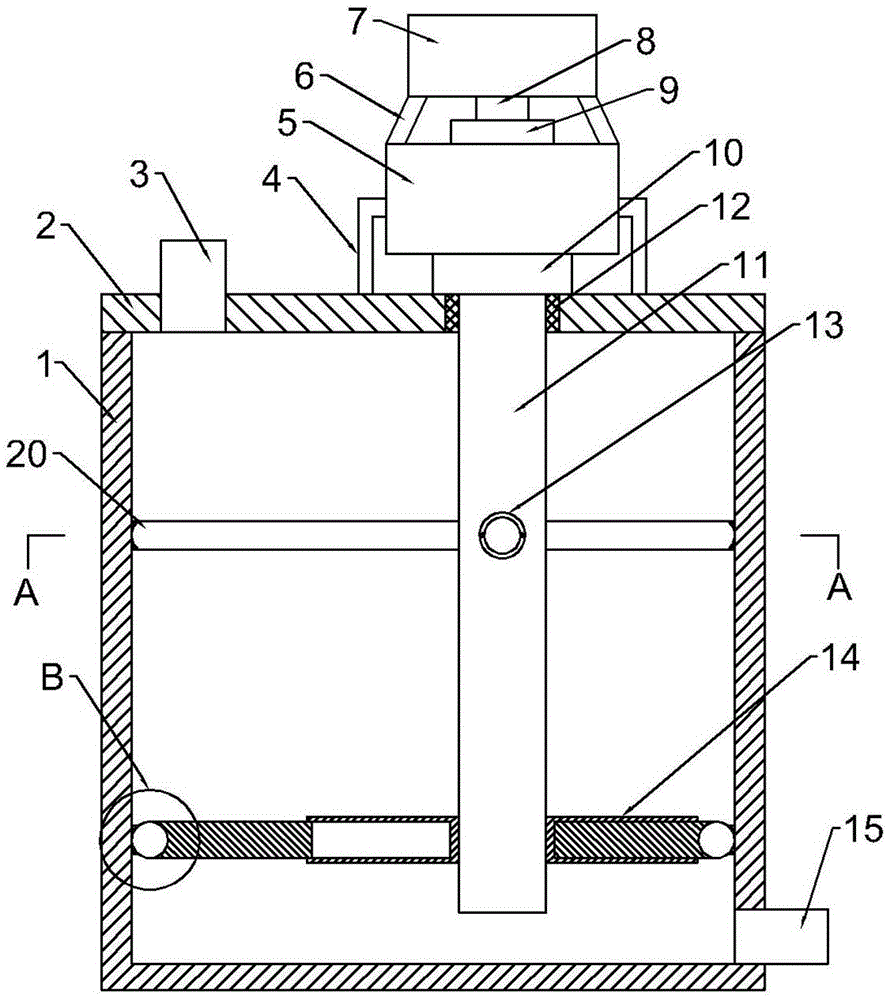

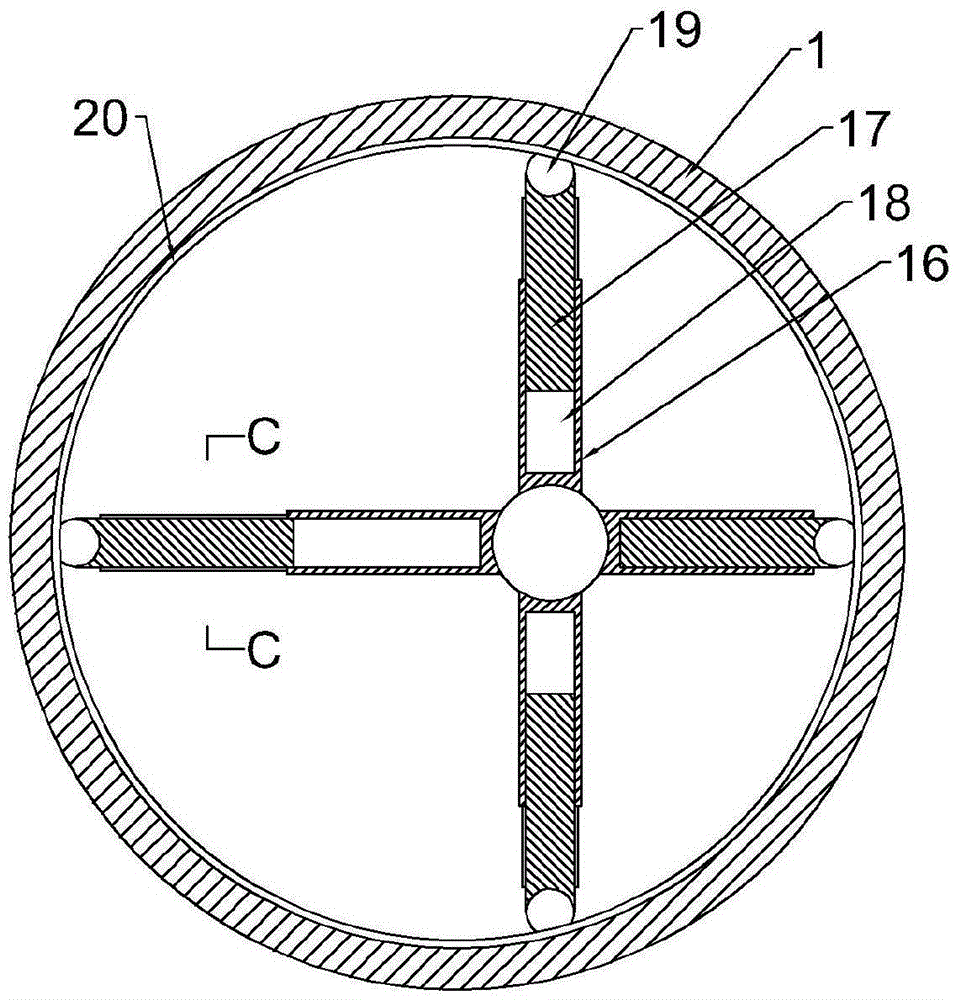

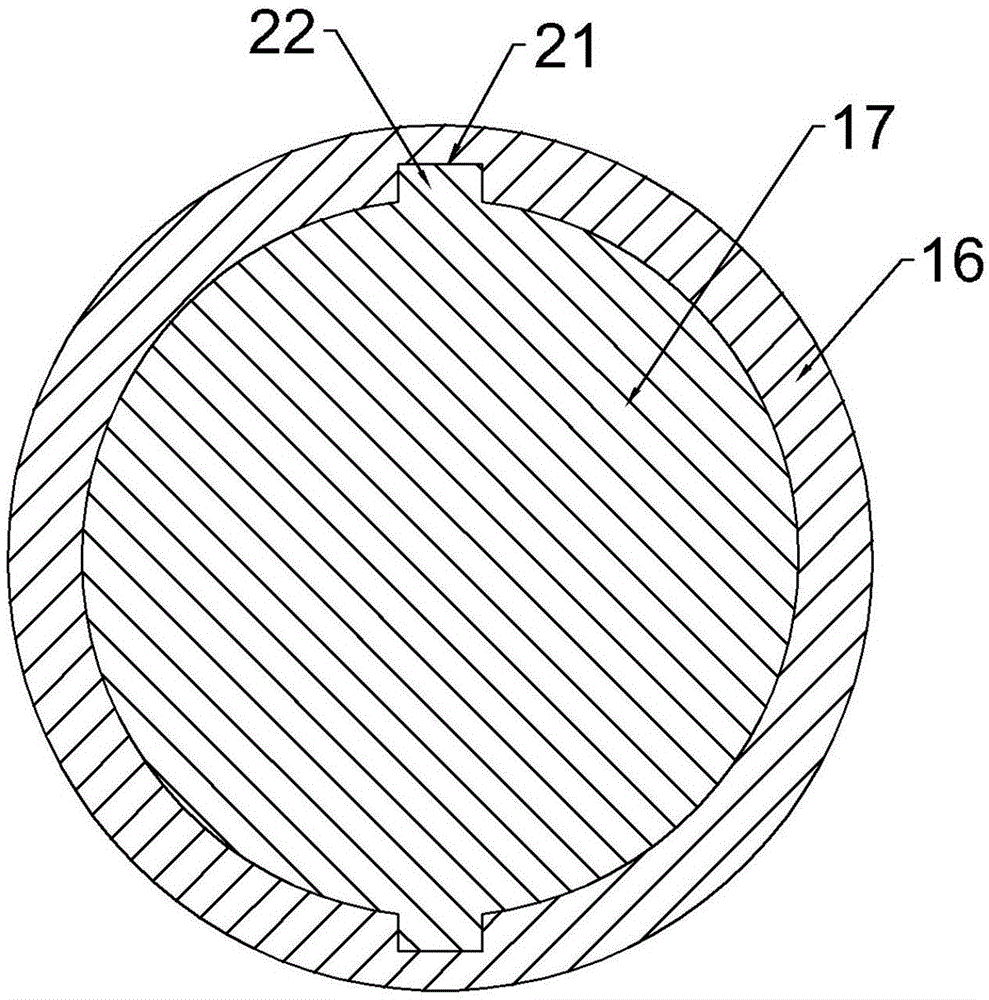

[0022] see Figure 1-3 , an eccentric variable blade length stirring device without dead angle, comprising a barrel body 1, the barrel body 1 is cylindrical in shape, the barrel body 1 is hollow inside, the bottom of the barrel body 1 is closed and the upper part is provided with an opening, and a seal is installed on the opening Cover 2, the upper left side of the cover 2 is provided with a feed inlet 3, the barrel body 1 is provided with a stirring shaft 11, the stirring shaft 11 is eccentrically arranged with the central axis of the barrel body 1, and the stirring shaft 11 is separated from the barrel body 1 The shortest distance to the inner wall is half of the farthest distance between the stirring shaft 11 and the inner wall of the barrel body 1. The upper end of the stirring shaft 13 passes through the sealing cover 2 and is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com