Fluid bed granulating drier and drying process thereof

A technology of boiling granulation and drying device, applied in the directions of drying gas arrangement, drying solid materials, sustainable manufacturing/processing, etc., can solve the problems of incomplete cleaning, complex structure, etc., and achieve no cross-contamination, fast heat transfer, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

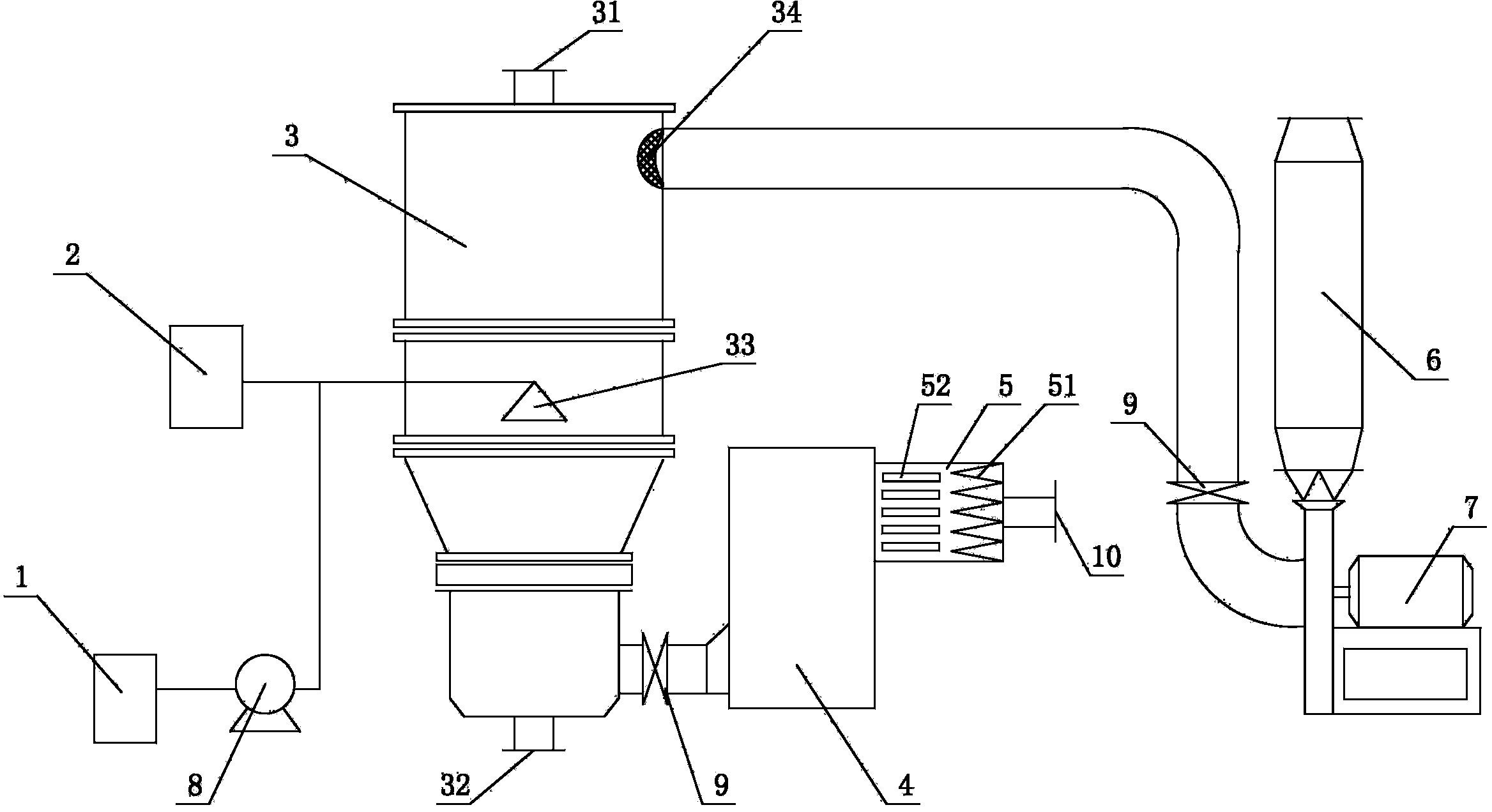

[0023] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0024] Such as figure 1 The fluidized granulation drying device shown includes a binder tank 1, an air compressor 2 and a fluidized fluidized bed 3. After the binder tank 1 passes through the binder outlet of the infusion pump 8 and meets the air outlet of the air compressor 2 Enter the fluidized fluidized bed 3 through the pipeline, and the end of the pipeline is connected with an atomizer 33; the lower half of the fluidized fluidized bed 3 is provided with a hot air inlet connected to the heater 4, An air outlet is provided, and the air outlet is connected with an exhaust fan 7 through a pipeline; the upper part of the heater 4 is connected with a filter 5, and the filter 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com