Horizontal type stirring ball-milling reactor for intensifying bentonite modification

A technology of agitating ball milling and reactors, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of unfavorable mixing of materials, insufficient mixing of materials, inconvenient feeding at any time, etc., to suppress heat-sensitive reactions , The ball milling temperature can be controlled, and the effect of improving the ball milling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

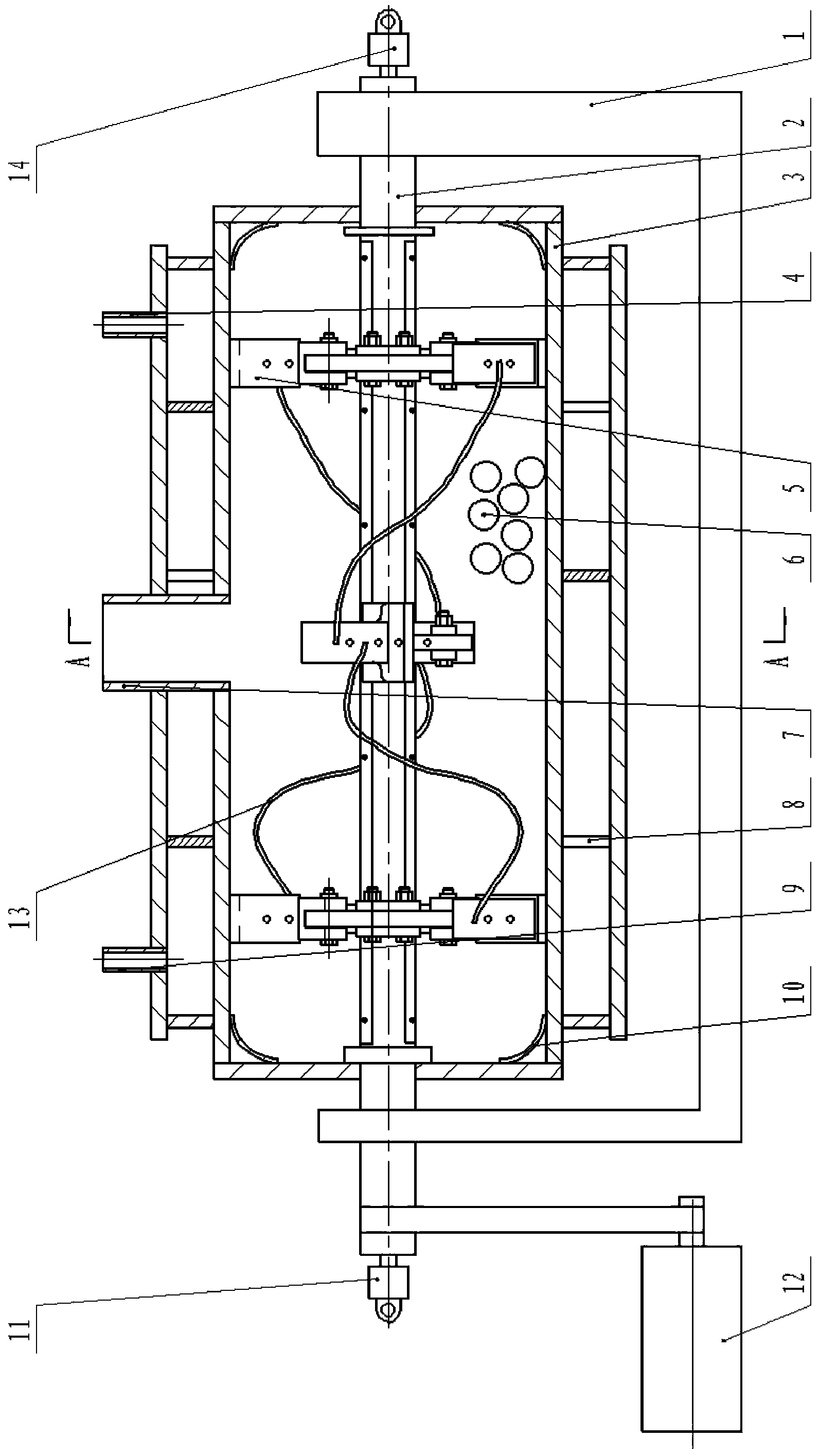

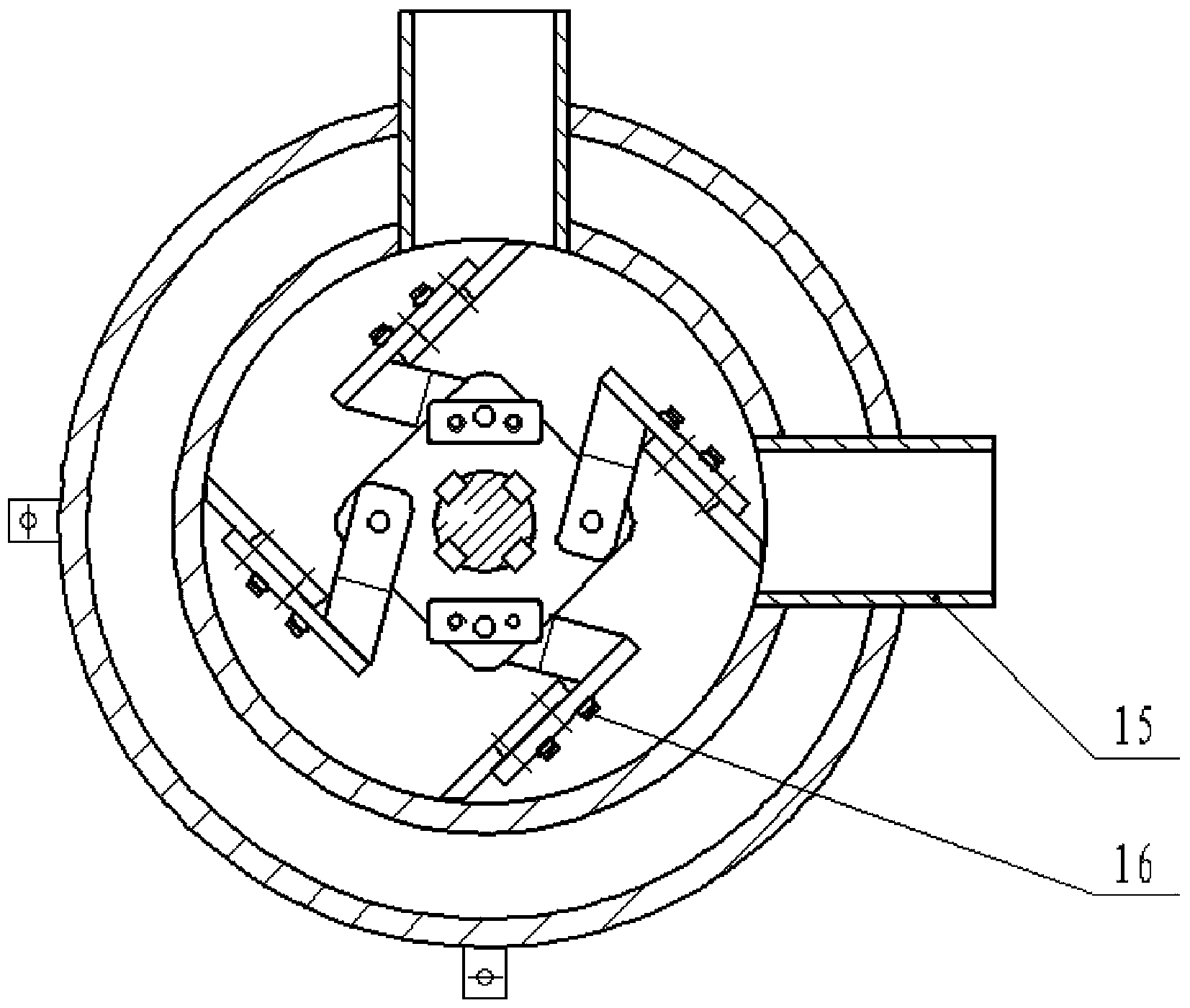

[0030] Such as figure 1 , figure 2 Shown, the pipeline of cooling system is prior art, not drawn among the figure, main structure of the present invention comprises support 1, the stirring shaft 2 that is installed on the support 1, the ball mill cylinder 3 that is installed on the stirring shaft 2, puts Grinding balls 6 in the ball mill cylinder 3. The ball mill cylinder 3 is divided into two layers: an outer cylinder and an inner cylinder. A partition 8 is provided between the outer cylinder and the inner cylinder. The partition 8 is provided with small holes for the circulation of cooling liquid. The outer cylinder A coolant guide channel is formed between the inner cylinder, and the outer cylinder is provided with a coolant inlet pipe 4, a feed port 7, a material outlet 15, and a coolant return pipe 9, and the coolant inlet pipe 4 and the coolant The return pipe 9 is respectively connected with the inlet coolant pipeline and the return coolant pipeline of the cooling sys...

Embodiment 2

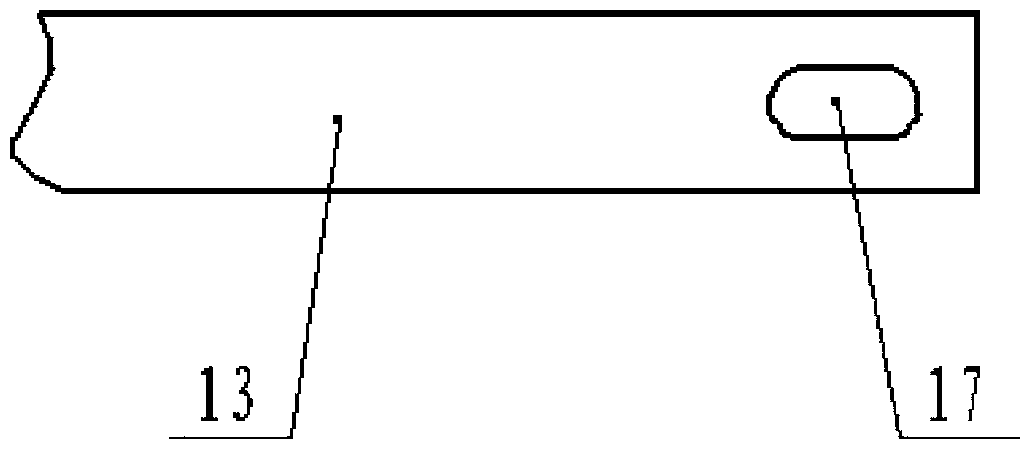

[0033] Such as image 3 As shown, the difference from Example 1 is that: the plow blade stirring blades 5 are equidistantly installed, and the two ends of the S-type stirring blade 13 have long holes 17, and the S-type stirring blades 13 pass through the long holes 17 and screws 16 Installed on the U-shaped frame of the plowblade stirring blades 5, the number of installations of the S-shaped stirring blades 13 in two adjacent groups of plowblade stirring blades 5 is 2.

[0034] In this embodiment, with respect to embodiment 1, the number of S-shaped stirring blades 13 installed in two adjacent groups of plow blade stirring blades 5 is 2, which increases the working area of the stirring device, and the driving force of the stirring device to the grinding ball 6 is 2. The effect is better, which is conducive to improving the efficiency of ball milling and reducing the time of ball milling. At the same time, a mixing test is carried out on viscous materials. During the stirring...

Embodiment 3

[0036] The difference from Embodiment 1 or 2 is that the stirring shaft 2 is a hollow structure, and the two ends are respectively provided with a left rotary joint 11 and a right rotary joint 14, and the left rotary joint 11 and the right rotary joint 14 are respectively connected with the inlet coolant of the cooling system. The line is connected to the return coolant line.

[0037] In this embodiment, the coolant enters the hollow structure of the stirring shaft 2 through the rotary joint 11, and returns to the cooling system from the rotary joint 14 to keep the stirring shaft 2 at a low temperature, reduce the temperature fluctuation of the ball mill cylinder 3, and facilitate the realization of constant temperature ball milling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com