Integrated machine of washing vegetables, washing bowl, and disinfecting

An all-in-one machine and vegetable washing technology, which is applied in the field of kitchen utensils, can solve the problems of high cost of washing dishes, long washing time, waste of water resources, etc., and achieve the effect of completely removing residual pesticides, shortening washing time, and reducing washing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

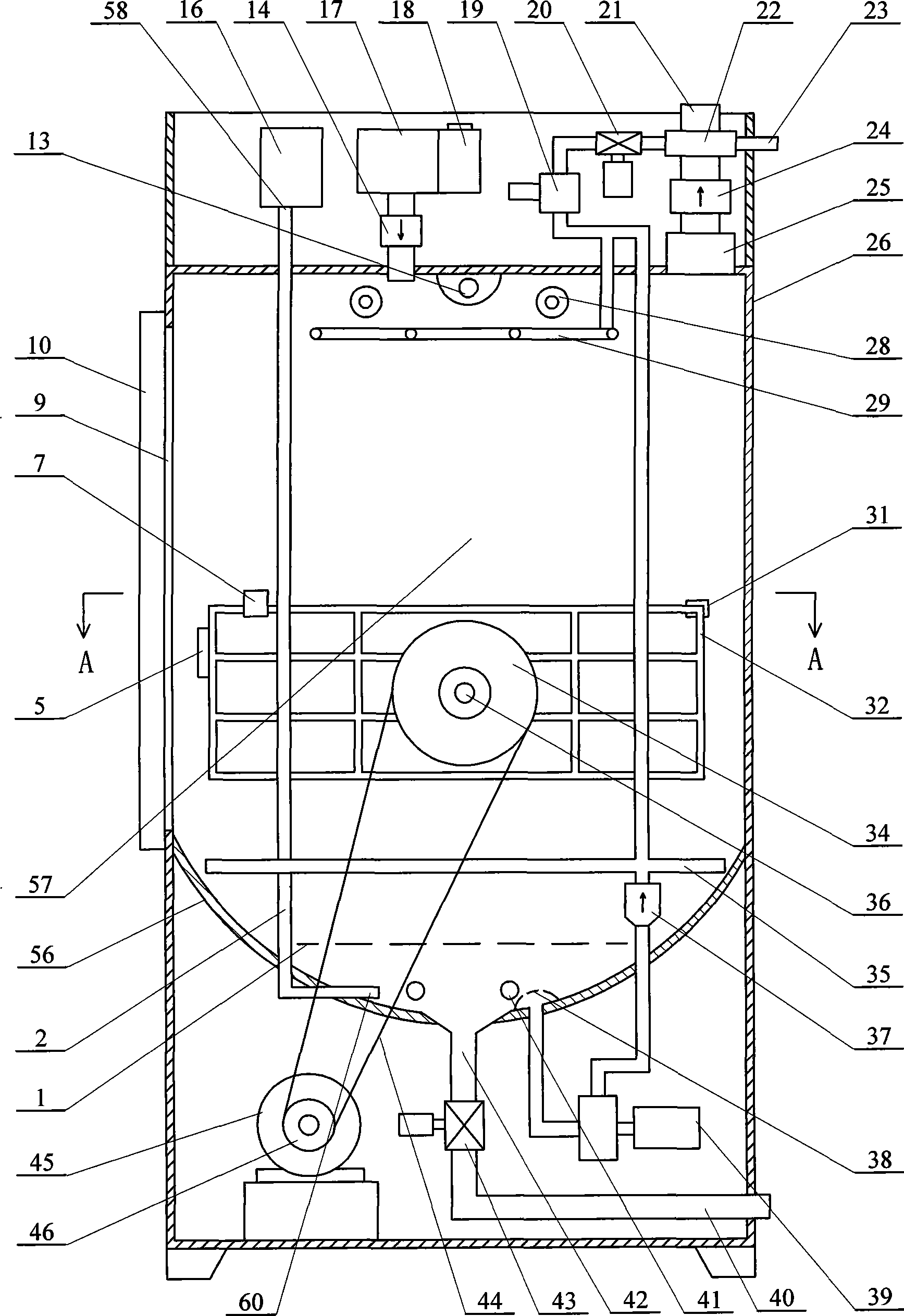

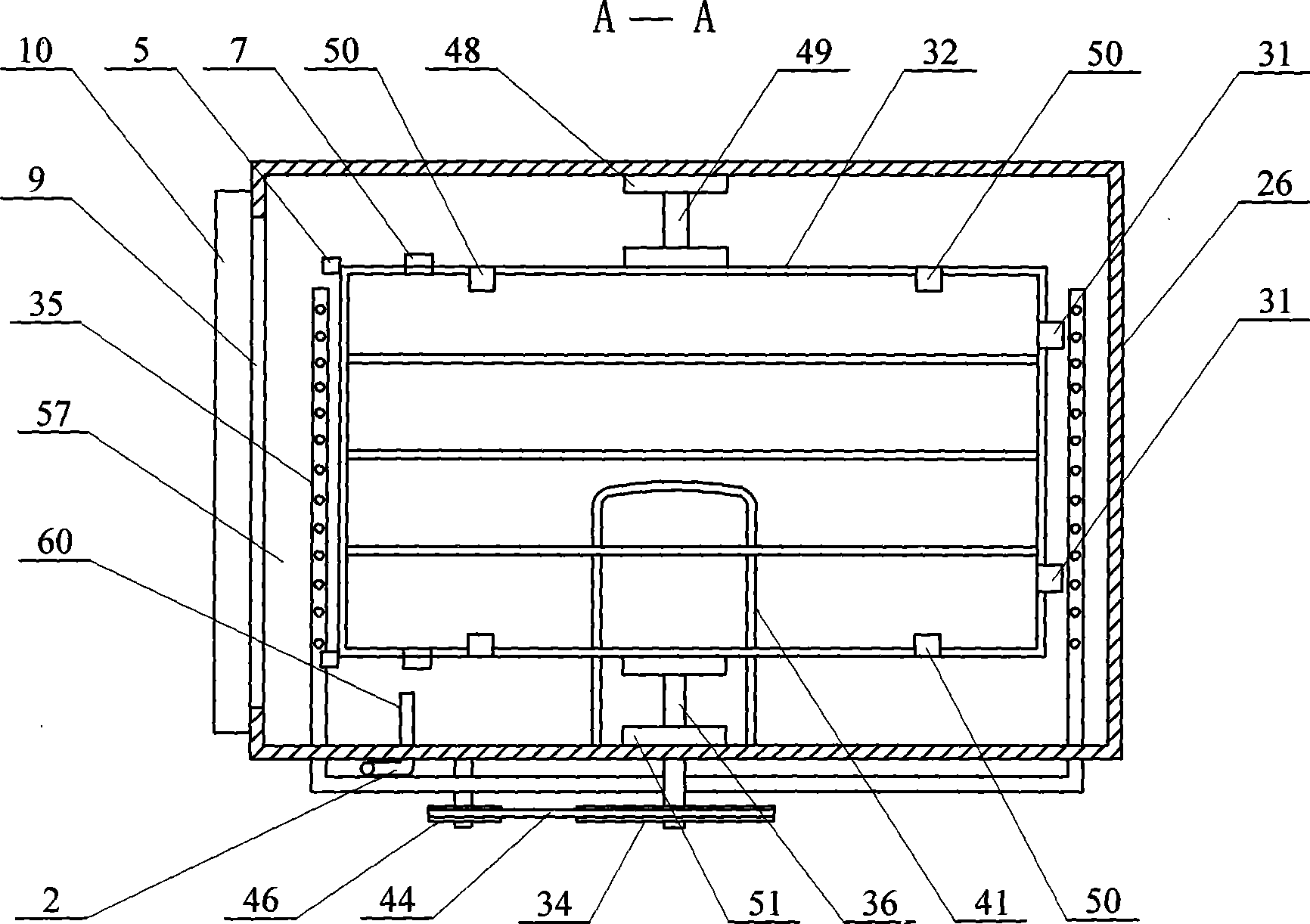

[0006] Specific implementation mode one: (see Figure 1 to Figure 6 ) This embodiment consists of an ozone tube 2, two latches 5, two buckles 7, a door body 10, a far-infrared ray generating device 13, a one-way air inlet door 14, an ozone generator 16, an air inlet fan 17, a pipeline water pump 19, an inlet Water solenoid valve 20, exhaust pipe 21, water inlet pipe 23, one-way exhaust door 24, exhaust fan 25, casing 26, ultraviolet sterilizing lamp tube 28, upper spray pipe 29, socket sleeve 31, movable basket support Frame 32, large sprocket 34, lower spray pipe 35, front axle 36, one-way water valve 37, water pump assembly 39, drain pipe 40, heating pipe 41, drain solenoid valve 43, chain 44, motor 45, small chain Wheel 46, rear axle sleeve 48, rear axle 49, casing pressure plate 50, front axle sleeve 51, arc-shaped inner bottom 56 and dish washing basket are formed, and arc-shaped inner bottom 56 is fixed on the lower part in the casing 26 One side of the casing 26 is pro...

specific Embodiment approach 2

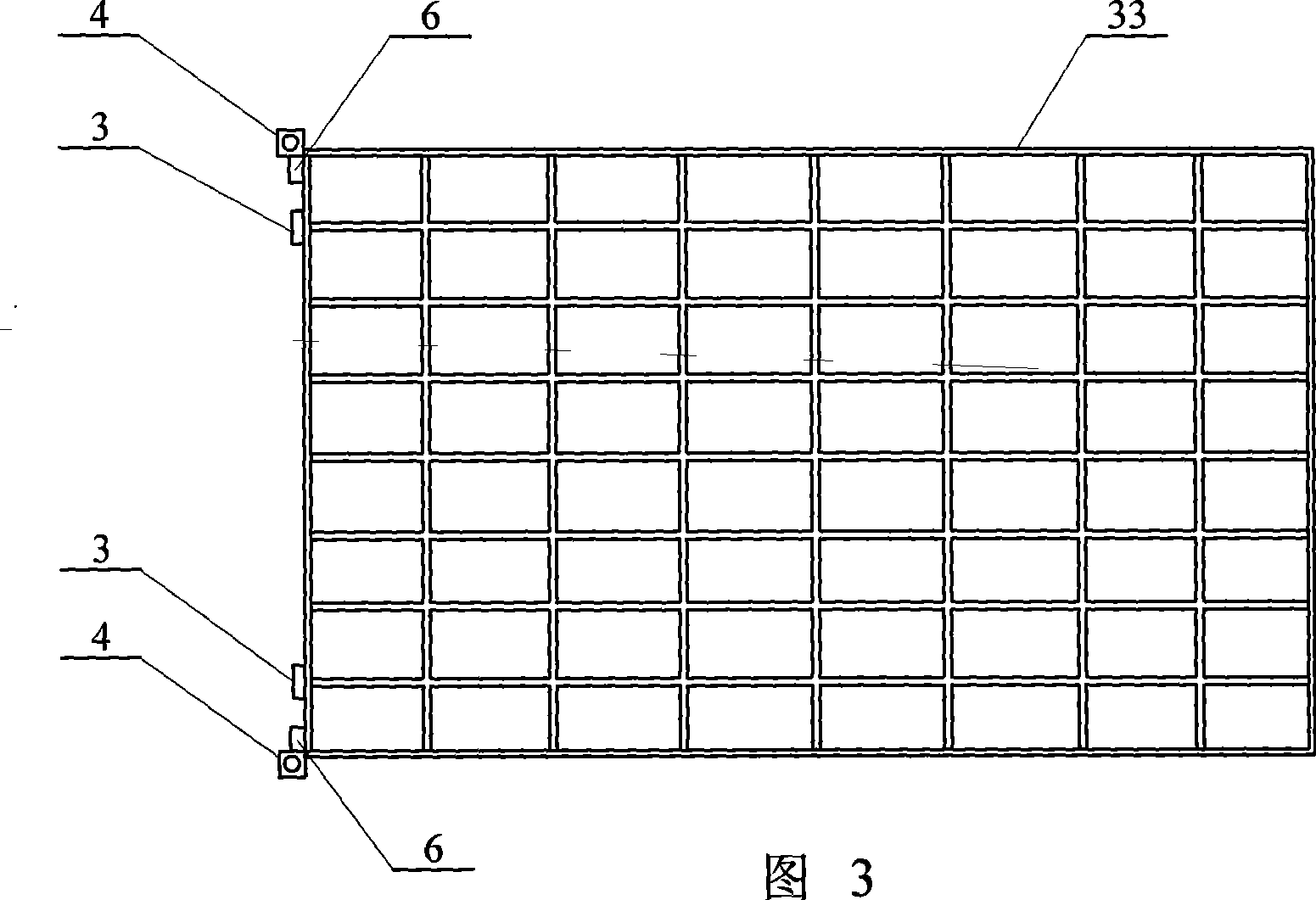

[0007] Specific implementation mode two: (see Figure 1 to Figure 6) The dishwashing basket of the present embodiment consists of a dishwashing basket 33, two dishwashing basket jacks 4, a semi-cylindrical net basket 11, a post 30, a dishwashing basket 54 and two dishwashing basket jacks respectively. 53 components, the washing basket 33 is a rectangular casing with an open top, and the middle part of the left end of the washing basket 33 is respectively fixed with a washing basket jack 4, and the two washing basket jacks 4 are connected with the movable Two latches 5 on the basket bracket 32 match, and the bottom of semicylindrical net basket 11 is an open structure, and post 30 is fixed on the right end of semicylindrical net basket 11 lower sides, and post 30 is connected with movable basket. The socket 31 on the body bracket 32 matches, the dishwashing basket 54 is a rectangular basket with an open top, and the two dishwashing basket jacks 53 are respectively fixed on ...

specific Embodiment approach 3

[0008] Specific embodiment three: (referring to Fig. 3, Figure 4 ) The difference between this embodiment and the second embodiment is that the left end of the vegetable washing basket 33 is an open structure, the left end of the vegetable washing basket 33 is provided with a basket door 52, and the lower end of the basket door 52 passes through the left end bottom of the vegetable washing basket 33. Hinge 3 is connected, and the upper end of basket door 52 is connected with the left end top of dish washing basket 33 by basket door inserter 6. In this embodiment, after the fruits and vegetables are cleaned, it is not necessary to take out the washing basket, and the washed fruits and vegetables can be poured into other containers only by opening the basket door. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com