Fully automatic deceleration jack auxiliary inspection vehicle

A decelerating top, fully automatic technology, applied in railway inspection vehicles, railway auxiliary equipment, railway car body parts, etc., can solve problems such as low reliability, achieve good rail grasping effect, prevent breakage, and evenly disperse the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

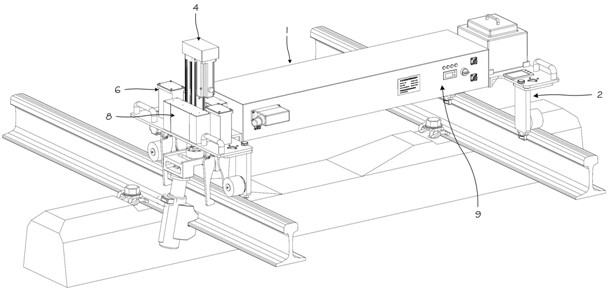

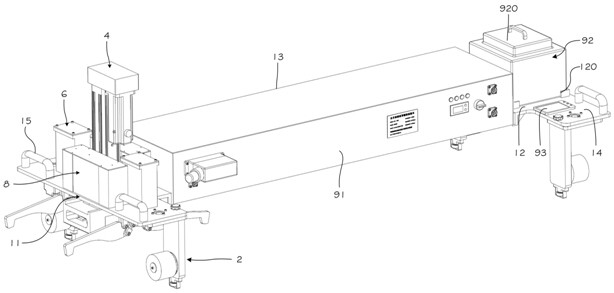

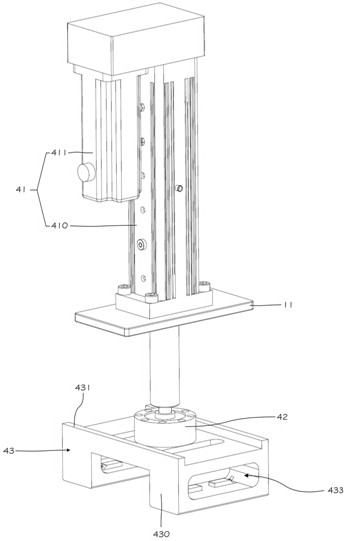

[0059] Figure 1 to Figure 10 It is a schematic view illustrating an embodiment of the fully automatic decelerator auxiliary inspection vehicle of the present invention. The fully automatic decelerator auxiliary inspection vehicle shown in the figure includes: a vehicle frame 1 and a control system 9 and execution components installed on the vehicle frame 1 to complete corresponding actions. The executive components include a running mechanism 2 that can walk freely on the railway rails, a pressure measuring mechanism 4 that can detect the oil and gas pressure and installation height of the retarder, a rail gripping mechanism 6 for offsetting the oil and gas pressure of the retarder, and a device that can detect the installation clearance of the retarder. Distance measuring mechanism 8.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com