Extraction process for large-scale production of radix angelicae extract in medicinal radix angelicae material

An extract and extraction technology of Angelica dahurica, applied in the direction of pharmaceutical formula, plant raw materials, plant/algae/fungus/moss components, etc., can solve the problems of inconvenient feeding and use of solid preparations, air environment, production environment pollution, and low content of active ingredients and other problems, to achieve the effect of easy promotion and use, less amount of solvent species, and high content of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

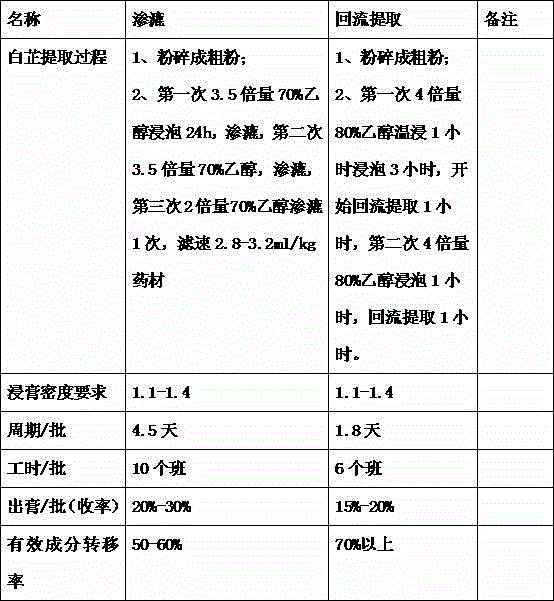

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one, its processing step is:

[0022] 1. Clean selection: the impurities and non-medicinal parts of Angelica dahurica are sorted out and discarded;

[0023] 2. Crushing: crushing the selected Angelica dahurica medicinal materials into coarse powder;

[0024] 3. One-time reflux: put 200kg of coarse powder of Angelica dahurica into the extraction tank, add 800kg of 75% ethanol to the extraction tank, heat to 60°C, soak for 1-1.5 hours, stop heating and soak for 3 hours, and control the heating temperature at 75-78°C to start timing reflux Extract for 1 hour to obtain a volume of 600L extract, and transport the extract to the liquid medicine storage tank;

[0025] 4. Secondary reflux: Add 1000kg of 75% ethanol to the extraction tank, soak at room temperature for 1 hour, control the heating temperature again at 75-78°C, start timed reflux extraction for 1 hour to obtain a volume of 780L extract, transport the extract to the liquid storage tank and combine tw...

Embodiment 2

[0028] Embodiment two, its processing step is:

[0029] 1. Clean selection: the impurities and non-medicinal parts of Angelica dahurica are sorted out and discarded;

[0030] 2. Crushing: crushing the selected Angelica dahurica medicinal materials into coarse powder;

[0031] 3. One-time reflux: put 200kg of coarse powder of Angelica dahurica into the extraction tank, add 900kg of 80% ethanol to the extraction tank, heat to 60°C and soak for 1-1.5 hours, stop heating and soak for 3 hours, and control the heating temperature at 75-78°C to start timed reflux Extract for 1 hour to obtain a volume of 650L extract, and transport the extract to the liquid medicine storage tank;

[0032] 4. Secondary reflux: Add 900kg of 80% ethanol to the extraction tank, soak at room temperature for 1 hour, reheat the temperature at 75-78°C and start reflux extraction for 1 hour to obtain a volume of 770L extract (vapor pressure≦0.1Mpa), and transport the extract to The liquid medicine storag...

Embodiment 3

[0035] Embodiment three, its processing step is:

[0036] 1. Clean selection: the impurities and non-medicinal parts of Angelica dahurica are sorted out and discarded;

[0037] 2. Crushing: crushing the selected Angelica dahurica medicinal materials into coarse powder;

[0038] 3. One-time reflux: put 200kg of coarse powder of Angelica dahurica into the extraction tank, add 1000kg of 85% ethanol to the extraction tank, heat to 60°C, soak for 1-1.5 hours, stop heating and soak for 3 hours, and control the heating temperature at 75-78°C to start timing reflux Extract for 1 hour to obtain a volume of 700L extract, and transport the extract to the liquid medicine storage tank;

[0039] 4. Secondary reflux: Add 800kg of 85% ethanol to the extraction tank, soak at room temperature for 1 hour, control the heating temperature again at 75-78°C and start timed reflux extraction for 1 hour to obtain a volume of 760L extract (vapor pressure≦0.1Mpa), and transport the extract To the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com