Method for preparing furfuraldehyde through hemicellulose by use of continuous flow microchannel reactor

A micro-channel reactor, channel reactor technology, applied in chemical recovery, organic chemistry and other directions, can solve the problems of ungiven reaction time, low yield, etc., to solve the problem of serious corrosion of equipment, small amount of reaction materials, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

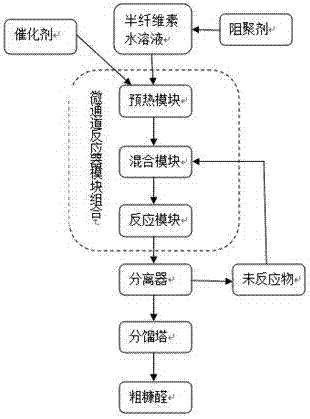

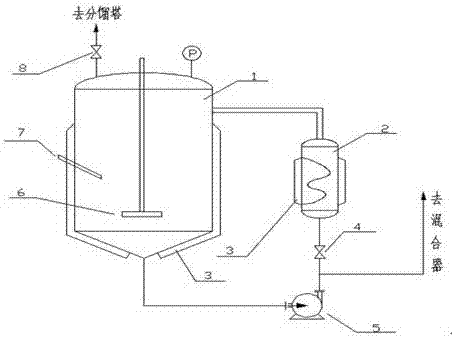

[0043] The continuous flow microchannel reactor used is the enhanced mass transfer microchannel reactor of Corning Corporation of the United States, (the mode of the reactor is "straight channel functional module" + "heart-shaped" structural functional module). figure 1 1. Determine the connection mode of the microchannel reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heating medium is heat transfer oil.

[0044] The hemicellulose raw material comes from the turbid liquid with a hemicellulose content of 15-25% or the solid matter with a hemicellulose content of 70-80% recovered from chemical fiber waste liquid, which is formulated into an aqueous solution with a hemicellulose content of 12wt%. Adding a polymerization inhibitor in the medium, the hemicellulose aqueous solution containing the polymerization inhibitor and the concentrated sulfuric acid of the catalyst are controlled by a metering pump to ...

Embodiment 2

[0052] The microchannel reactor is an enhanced mass transfer microchannel reactor from Corning Corporation of the United States. The reaction system is assembled from multiple modules; the material of the module is silicon carbide and special glass; the microchannel structure in the module is divided into direct current channel There are two types of structure and enhanced mixed channel structure, the straight channel is a tubular structure, the enhanced mixed channel structure is a heart-shaped structure, and the hydraulic diameter of the channel is 8mm; the continuous flow microchannel reactor used (straight channel functional module + "heart-shaped" Structural function module) process, refer to figure 1 1. Determine the connection mode of the microchannel reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heating medium is heat transfer oil.

[0053] The hemicellulose raw material comes from the turbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com