Low-altitude rail transportation network for fast physical distribution

A technology of rail transportation and rail, which is applied in the field of rapid logistics and low-altitude rail transportation network, can solve the problems of many stops in the middle, slow transportation speed, and high energy consumption of transportation, so as to reduce maintenance costs, reduce support strength requirements, reduce operating costs and noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

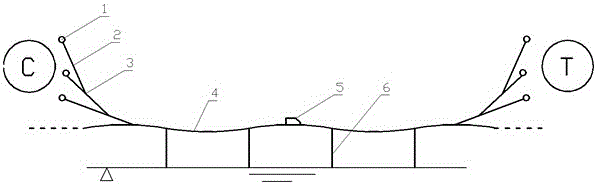

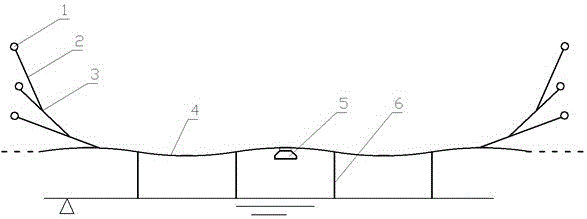

[0044] Embodiment 1: see figure 1 , The rapid logistics low-altitude rail transportation network consists of station 1, branch rail 2, turnout 3, main rail 4, rail car 5 and pillar 6, and also includes power supply system and control system.

[0045] The station 1 is set at the beginning or end of the tracks 2 and 4, and the branch track 2 and the branch track 2, and between the branch track 2 and the main track 4 are connected together by a turnout 3, and the turnout 3 is an automatic turnout; the pillar 6 is installed on Below the track 2, 4 along the line, the track 2, 4 is erected in the air through the pillar 6, the rail car 5 runs along the track 2, 4, the track 2, 4 between the adjacent switch 3 is a seamless continuous track, the main The track 4 or the branch track 2 is a straight track or a wave-shaped curved track. The middle section of the curved track hangs down naturally to form a circular arc. The lowest point of the circular arc is suspended in the air and can ...

Embodiment 2

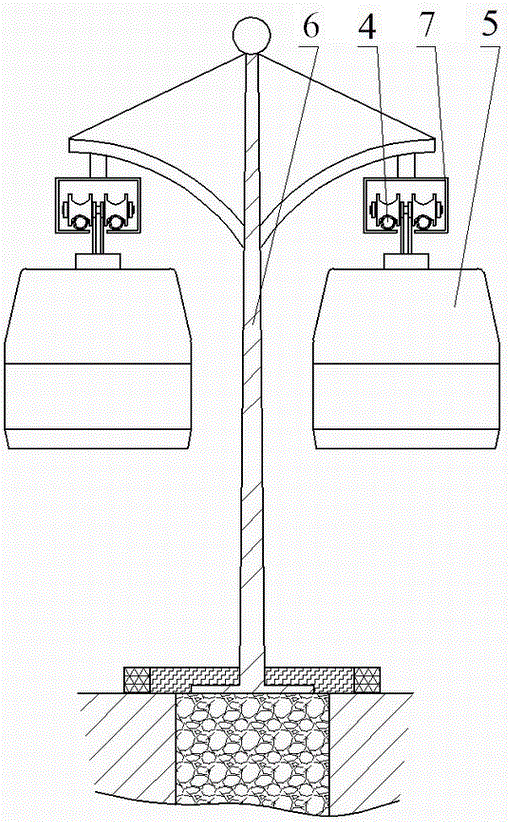

[0064] Example 2: see figure 2 and image 3 , rail car 5 is suspended and travels below track 4, and track 4 is installed in track box 7, and track 4 is erected in the air by track box 7 relying on pillar 6, and track car 5 is suspended in track box 7 below and walks along track 4 below. figure 2 In , there are two track lines, set side by side. Orbit lines can also be set to one, or more lines can be set side by side, and the other parts are basically the same as those in Embodiment 1. The rail car 5 is suspended below the track box 7. The advantage is that the center of gravity of the rail car 5 is low and relatively stable.

Embodiment 3

[0065] Embodiment 3: see Figure 4 and Figure 5 , the track 4 is divided into upper and lower layers, and there are rail cars 5 traveling above and below the track 4. The track 4 above is directly installed on the pillar 6, and the rail car 5 travels above the track 4. Below track 4 is installed in track box 7, and track 4 is erected in the air by track box 7 and relies on pillar 6, and rail car 5 is suspended in track box 7 below and walks along track 4 below. There are two track lines on the upper and lower floors, arranged side by side. The track lines of the upper layer and the lower layer can also be set to one or more. Other settings are basically the same as in Embodiments 1 and 2. Its advantage is that it is set up as two layers to increase the transportation volume, increase the utilization rate of the system, and improve the operating efficiency and travel efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com