Construction method of shield departure and reception binary slurry injection

A construction method and double-slurry technology, which can be used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of high cost and large construction volume, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Injection of double liquid slurry in the hole of shield tunneling

[0054] The shield tunnel construction of a certain subway project in Guangzhou adopts the double-slurry construction method of the shield tunnel entering and exiting the present invention. The maintenance structure of the station at the receiving end is Φ1200 manual digging piles when the shield exits the tunnel.

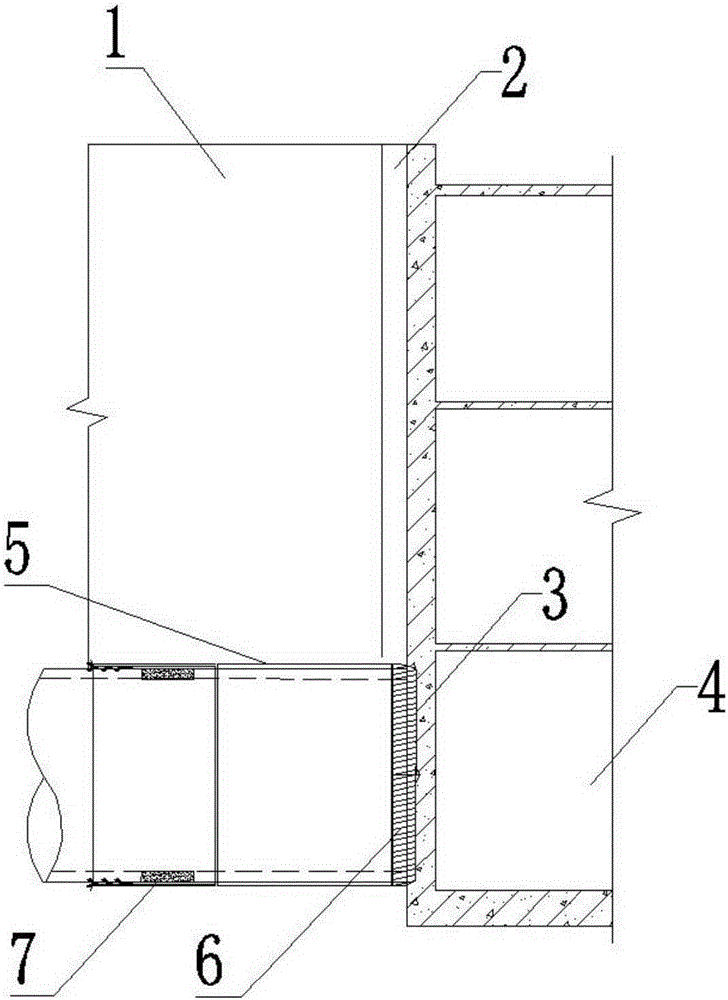

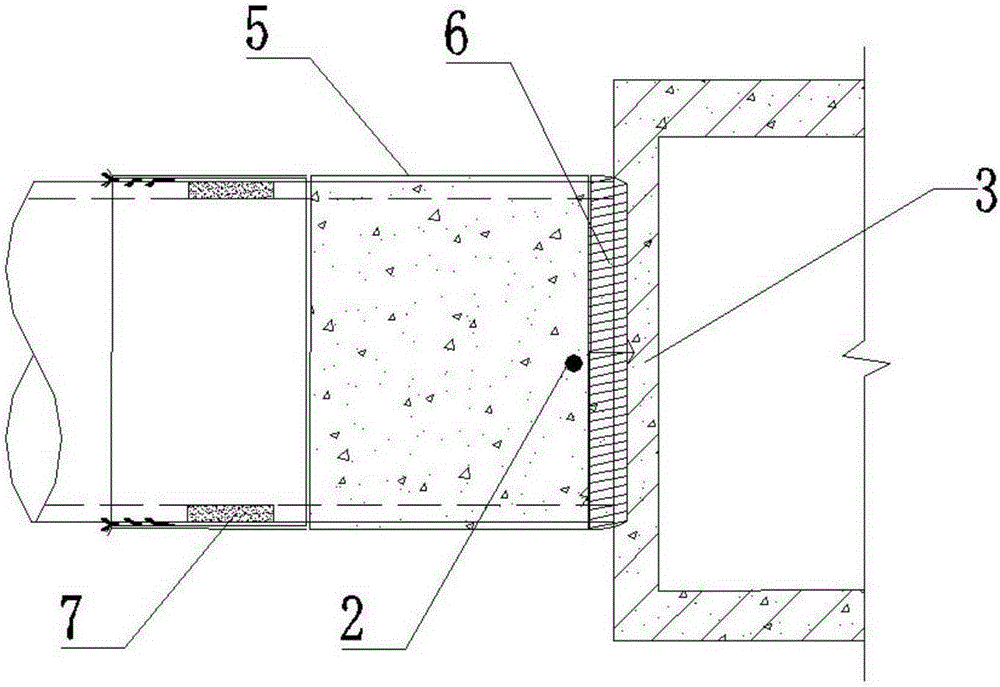

[0055] Such as figure 1 and figure 2 As shown in the figure, the station maintenance structure 3 of the subway station 4 is shown in the figure. The construction process of the shield machine 5 on the station maintenance structure 3 is as follows: the shield machine 5 advances until the cutter head 6 enters the maintenance pile of the station maintenance structure 3 , pause the propulsion, and use the tunnel drilling rig to guide the hole from the distance of 800mm outside the maintenance pile of the station maintenance structure 3 to the position 200mm above the main body of the shield mac...

example 2

[0058] Cave door plugging and double slurry injection

[0059] In a project of Shenzhen Metro, the end of the shield machine was reinforced with double-tube high-pressure rotary grouting piles. During the tunneling process of the shield machine, the waterproof measures of the portal were damaged, sand gushing occurred at the portal, and the ground collapsed.

[0060] When a dangerous situation occurs, the construction method of the present invention is adopted for emergency rescue. After the ground hole is introduced to the sand gushing position, the ratio of cement slurry and water glass is adjusted so that the solidification time of the slurry is controlled within 25 seconds. Compared with injecting the slurry, after 2 minutes of injection, the slurry emerges from the sand gushing part, immediately suspends the grouting after 15 seconds, and pauses again for 15 seconds after the sand gushing part emerges, and repeats the cycle several times Finally, the sand gushing channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com