Wind driven generator base anchor pile construction technology taking rock as bearing stratum

A technology of wind power generators and construction techniques, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the safety hazards caused by the construction equipment and tools of surrounding farmhouses, the long approval time for blasting operations, and the complexity of purchasing civil blasting materials and other problems, to achieve the effect of less excavated earth and rock, small footprint, and strong cementing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

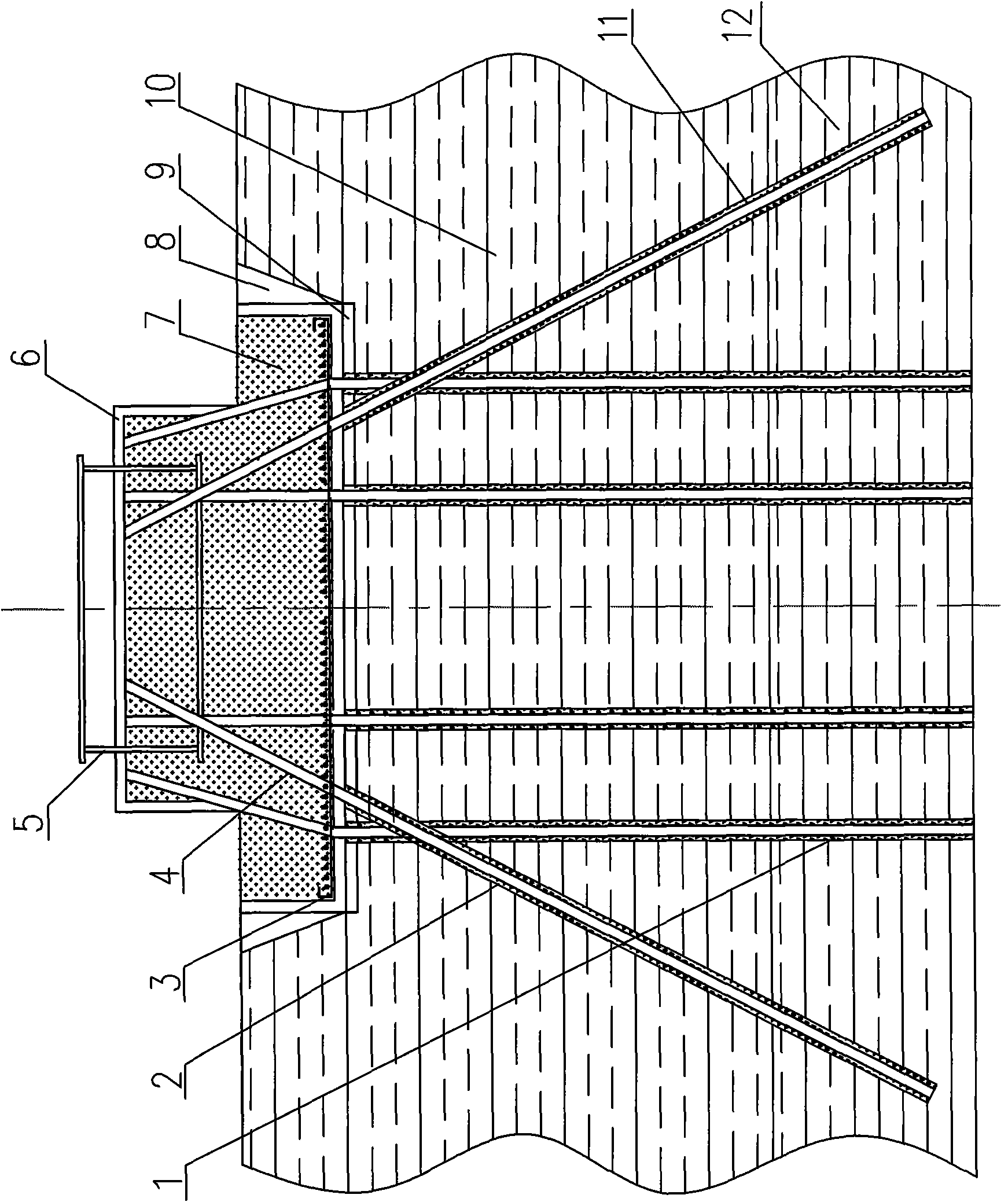

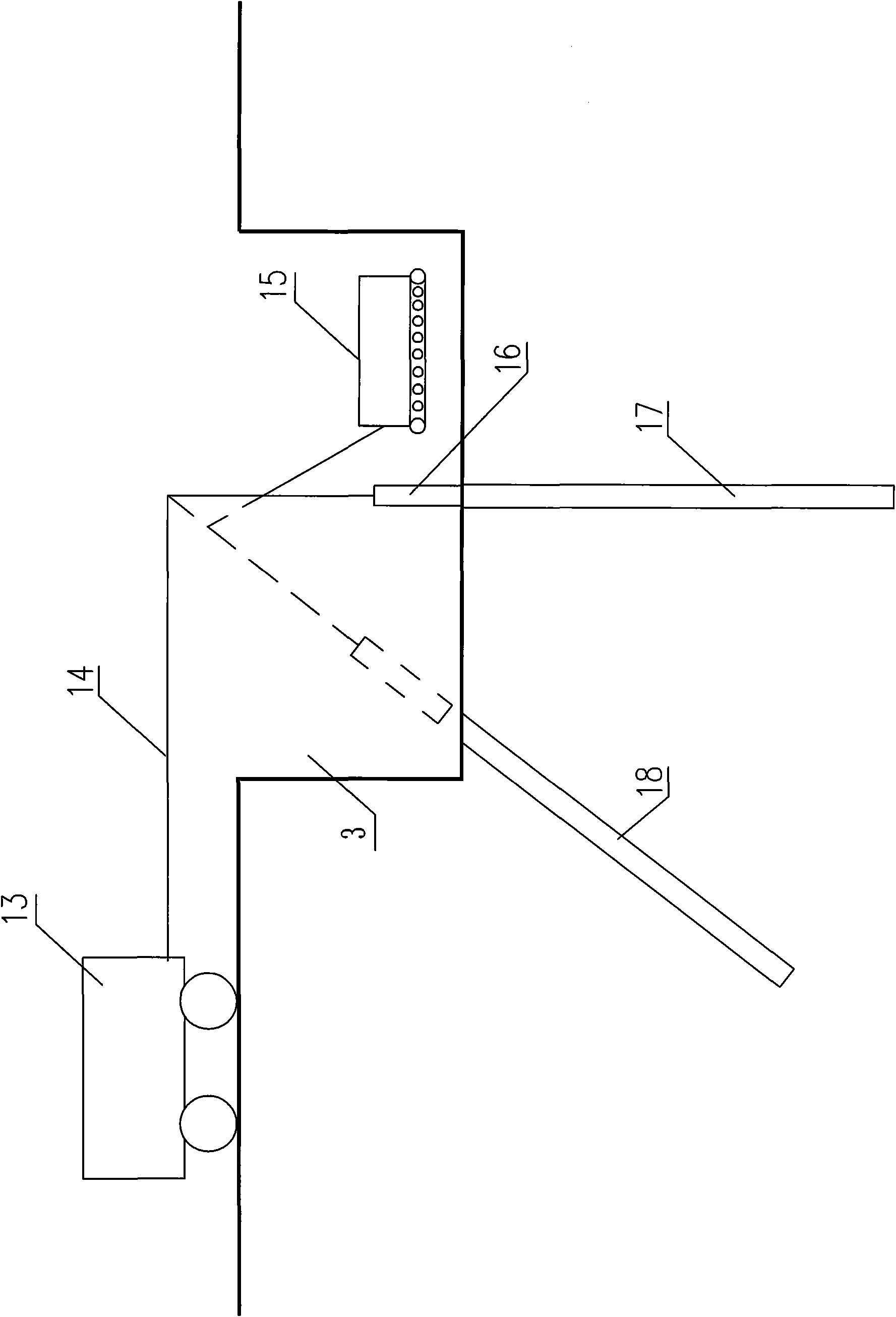

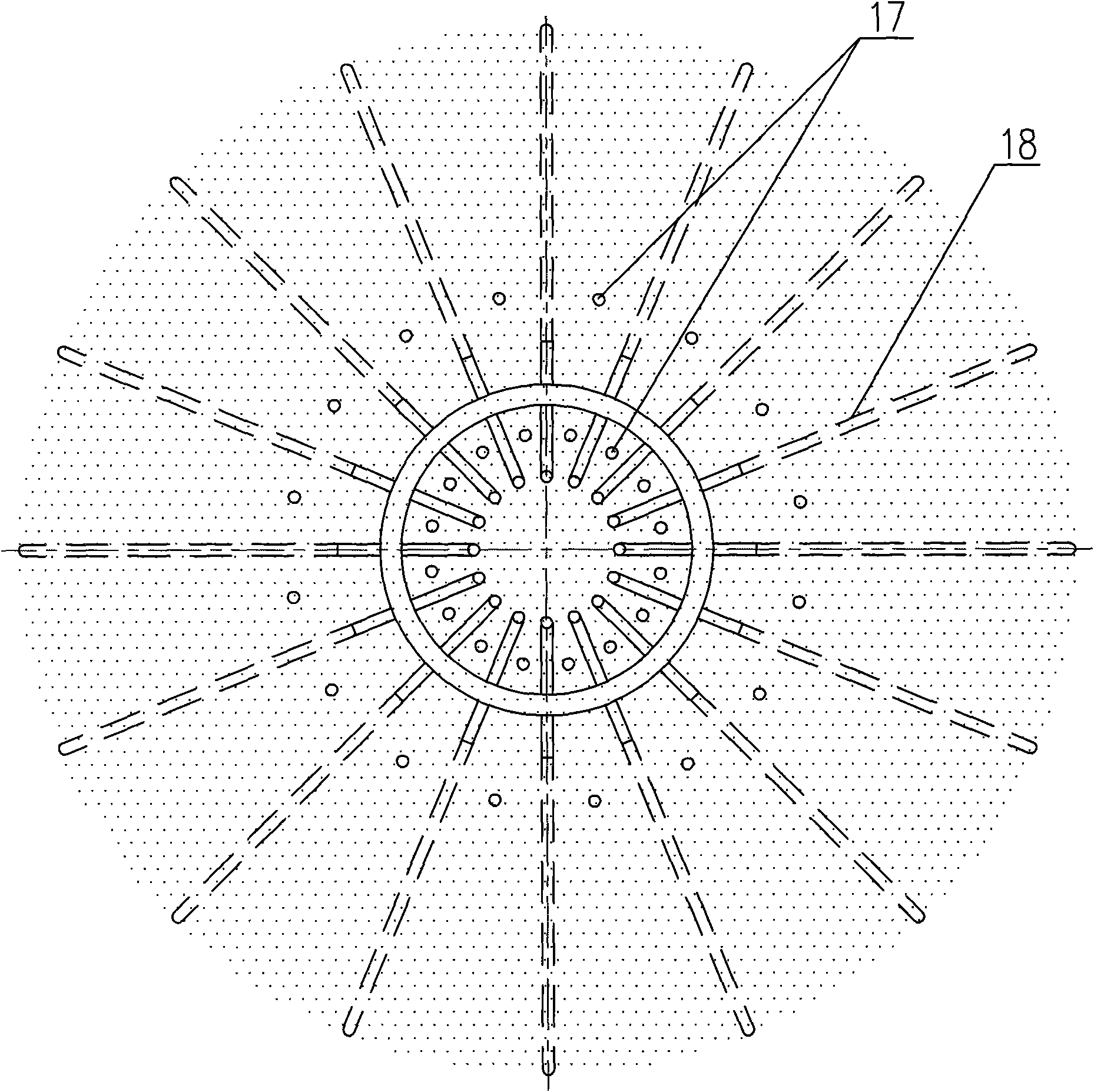

[0019] As shown in the figure, the construction process of the wind turbine foundation anchor pile with rock as the bearing layer includes the following steps: 1. Clean up the skin covering and loose and broken rock within the design diameter, excavate the earth and rock, and strip the weathered rock. Manually or mechanically remove to the depth of the designed foundation pit 8, pour a 250-350 mm concrete cushion 9 in the foundation pit 8, arrange the hole positions of the foundation anchor piles and stabilize the down-the-hole drilling rig 15 after the strength of the concrete cushion 9 reaches the standard, and install Install air compressor 13 and impactor 16, connect air compressor 13 and impactor 16 with high-pressure gas pipe 14; According to the lithology of the rock, the feeding pressure of the down-the-hole drilling rig 15 is controlled and adjusted to 0.8-1.5 tons, and the air volume and air pressure of the air compressor 13 are adjusted at the same time. The air volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com