Reinforced Concrete Pile Embankment and Its Construction Method

A technology of reinforced concrete and reinforced concrete slabs, applied in the direction of jetties, embankments, breakwaters, etc., can solve the problems of difficulty, long construction period, and high construction risk, and achieve the effect of small influence range, high construction degree, and good overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

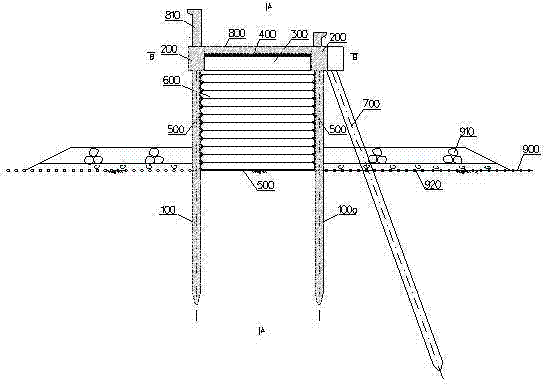

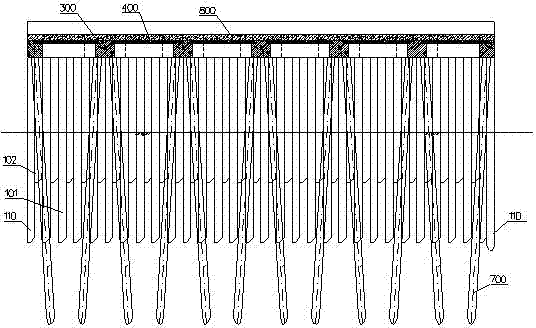

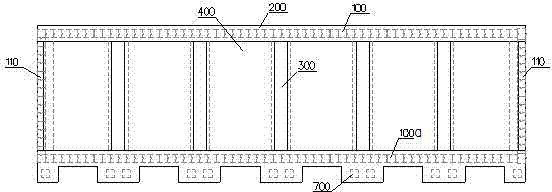

[0042] see figure 1 , 2 , 3. The reinforced concrete pile embankment shown includes two rows of parallel reinforced concrete sheet piles 100, 100a, and each row of reinforced concrete sheet piles 100, 100a is composed of alternately arranged long sheet piles 101 and short sheet piles 102 (see figure 2 ), the long sheet pile 101 and the short sheet pile 102 are both prefabricated piles, the pile top of the long sheet pile 101 is flush with the pile top of the short sheet pile 102, and the part of the long sheet pile 101 inserted into the foundation is larger than that of the short sheet pile 102 part of the. The connection between the long sheet pile 101 and the short sheet pile 102 is a tongue and groove connection, and rubber waterstop stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com