Absorbent for flue gas desulfurization and preparation method and application of composition of absorbent

The technology of an absorbent and a composition is applied in the fields of absorbent for flue gas desulfurization and its preparation and composition, which can solve the problems of low strength, high cost, complicated preparation process, etc., and achieve high recycling rate, Effects of cost reduction and less dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]

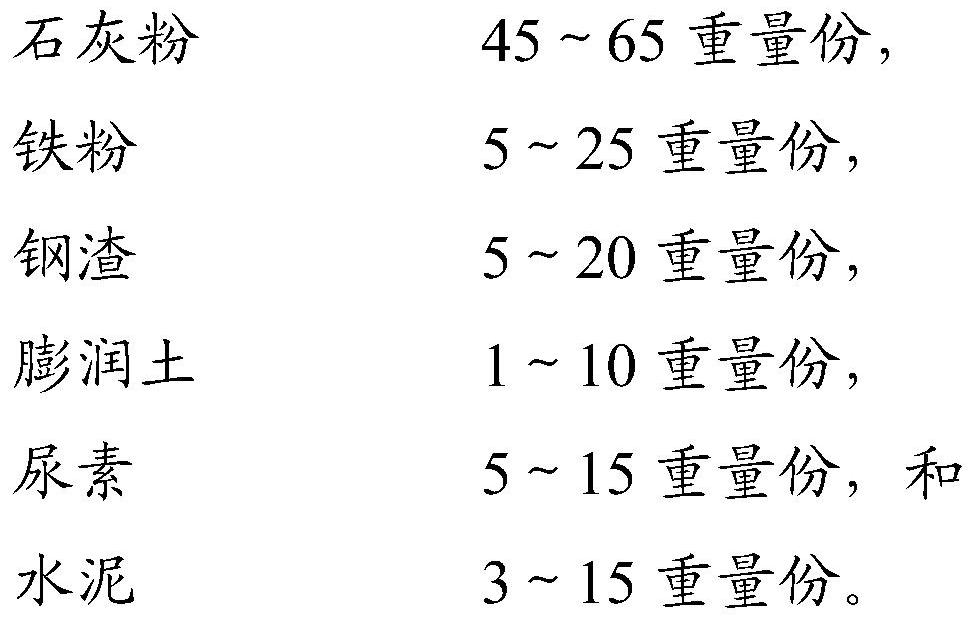

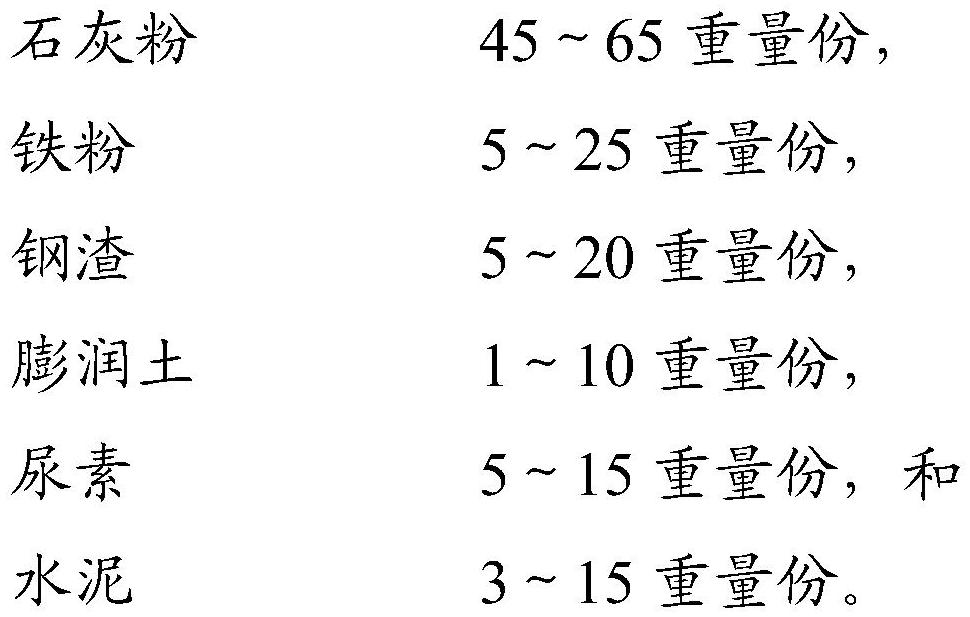

[0038] The preparation method of the present invention comprises the following steps: (1) dry mixing lime powder, iron powder, steel slag, bentonite, urea and cement to obtain a first mixture; (2) wet mixing the first mixture with water to obtain a second mixture; (3) The second mixture is granulated, and then dried to obtain an absorbent. The amount of each raw material is as described above, and will not be repeated here.

[0039] Dry mixing can be performed in a kneader. The dry mixing time is 10-30 min; preferably 10-20 min; more preferably 15-20 min.

[0040] Wet mixing can be performed in a kneader. Water can be added to the first mixture in multiple times, for example 3-5 times. The wet mixing time may be 20-50 min; preferably 25-40 min; more preferably 30-40 min.

[0041] Granulation can be performed in a granulator.

[0042] The drying temperature may be 150-300°C; preferably 200-300°C; more preferably 200-250°C. The drying time may be 1-5 hours; pref...

Embodiment 1~3

[0055] Lime powder, iron powder, steel slag, bentonite, urea and cement were dry mixed in a kneader for 15 minutes to obtain the first mixture;

[0056] Add deionized water into the first mixture three times, and wet mix for 30 minutes to obtain the second mixture;

[0057] The second mixture is granulated in a granulator to obtain cylindrical composite particles; the particle diameter of the composite particles is 5-10 mm, and the length is 8-15 mm.

[0058] The composite particles were dried at 200°C for 3 hours, and the absorbent was obtained after cooling.

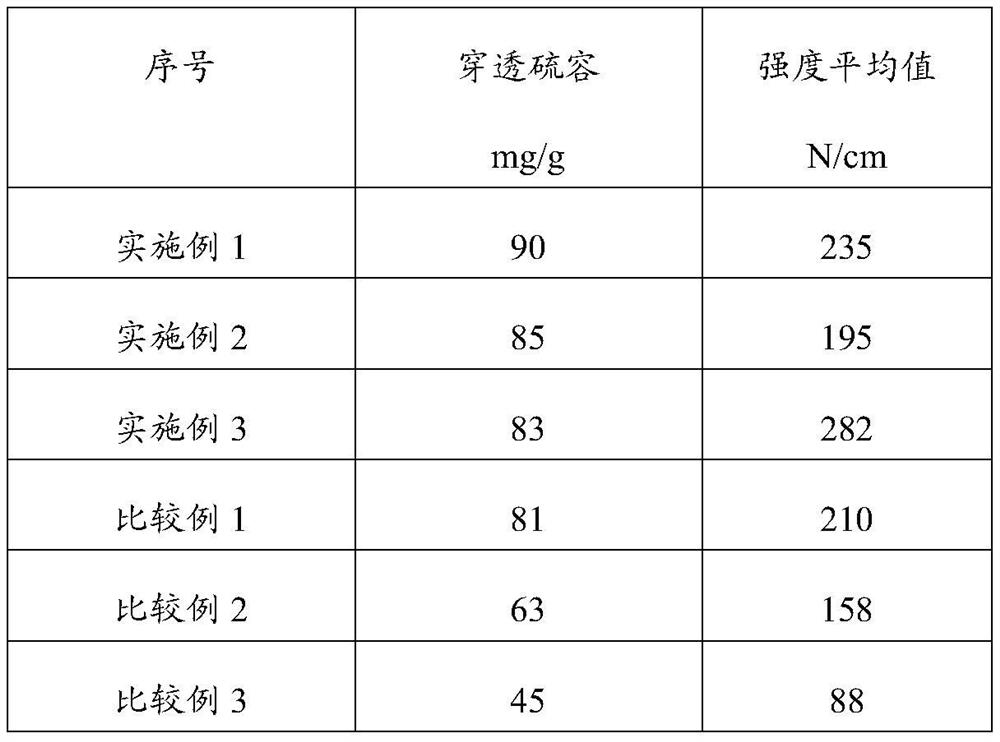

[0059] The amount of each raw material is shown in Table 1, and the performance of the absorbent is shown in Table 2.

[0060] Table 1

[0061] Example 1 Example 2 Example 3 Lime powder (parts by weight) 56 58 53 Iron powder (parts by weight) 10 10 10 Steel slag (parts by weight) 12 12 12 Bentonite (parts by weight) 4 4 4 Urea (parts by weight) 10 8 13 Ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakthrough sulfur capacity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com