Method for preparing absorbing agent for medium-temperature gas desulfurization

A kind of adsorbent and gas technology, applied in the direction of chemical instruments and methods, selection of absorbent solid gas purification, other chemical processes, etc., to achieve the effect of simple preparation process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Commercially available γ-Al 2 o 3 Dry at 200°C for 2 to 4 hours, cool down in a desiccator to prepare γ-Al 2 o 3 carrier.

[0024] γ-Al with a particle size of 2-3mm 2 o 3 50g of the carrier was placed in a beaker and mixed with 40.00ml of a pre-prepared solution of 0.79mol / L ferric nitrate (theoretical value of the mass percentage of iron oxide in the adsorbent was 5.0%). Immerse at room temperature and -0.06MPa vacuum for 4 hours at equal volume, then at room temperature and at normal pressure, immerse at equal volume for 4 hours with ultrasonic power of 150W.

[0025] After drying at 70°C and -0.10MPa vacuum for 11h, put it in a muffle furnace, keep it at 700°C for 2h, and cool it down to room temperature naturally to obtain the adsorbent I for desulfurization.

[0026] The desulfurization performance of the adsorbent was evaluated at 500°C, the breakthrough time was 4.8h, and the sulfur capacity was 2.9g / 100g adsorbent.

Embodiment 2

[0028] γ-Al with a particle size of 2-3mm 2 o 3 50g of the carrier was placed in a beaker and mixed with 40.00ml of a pre-prepared solution of 1.57mol / L ferric nitrate (theoretical value of the mass percentage of iron oxide in the adsorbent was 10.0%). Firstly impregnate at room temperature and -0.09MPa vacuum with equal volume for 7 hours, and then at room temperature and normal pressure with ultrasonic power of 350W, impregnate with equal volume for 1 hour.

[0029] After drying at 60°C and -0.09MPa vacuum for 14h, put it in a muffle furnace, keep it warm at 600°C for 2.5h, and cool down to room temperature naturally to obtain the adsorbent II for desulfurization.

[0030] The desulfurization performance of the adsorbent was evaluated at 450, 500 and 550°C respectively, the breakthrough time was 10.3, 11.8 and 11.2h, and the sulfur capacity was 5.1, 6.9 and 6.2g / 100g adsorbent.

Embodiment 3

[0032] γ-Al with a particle size of 2-3mm 2 o 3 50g of the carrier was placed in a beaker and mixed with 40.00ml of a pre-prepared solution of 2.35mol / L ferric nitrate (theoretical value of the mass percentage of iron oxide in the adsorbent was 15.0%). Immerse at room temperature and -0.07MPa vacuum for 6 hours at equal volume, then at room temperature and at normal pressure, immerse at equal volume for 2 hours with ultrasonic power of 250W.

[0033] After drying at 50°C and -0.09MPa vacuum for 12h, put it in a muffle furnace, keep it at 600°C for 2h, and cool it down to room temperature naturally to obtain the adsorbent III for desulfurization.

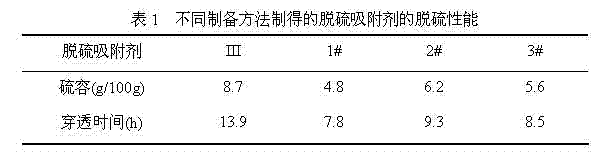

[0034] The desulfurization performance of the adsorbent was evaluated at 500°C, the breakthrough time was 13.9h, and the sulfur capacity was 8.7g / 100g adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com