Molecular sieve desulfurizer containing copper ion and potassium ion and preparation method thereof

A molecular sieve and desulfurizer technology, applied in the field of molecular sieve, can solve the problems of low desulfurization efficiency, and achieve the effects of improving adsorption efficiency, increasing adsorption capacity, and reducing the number of regenerations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

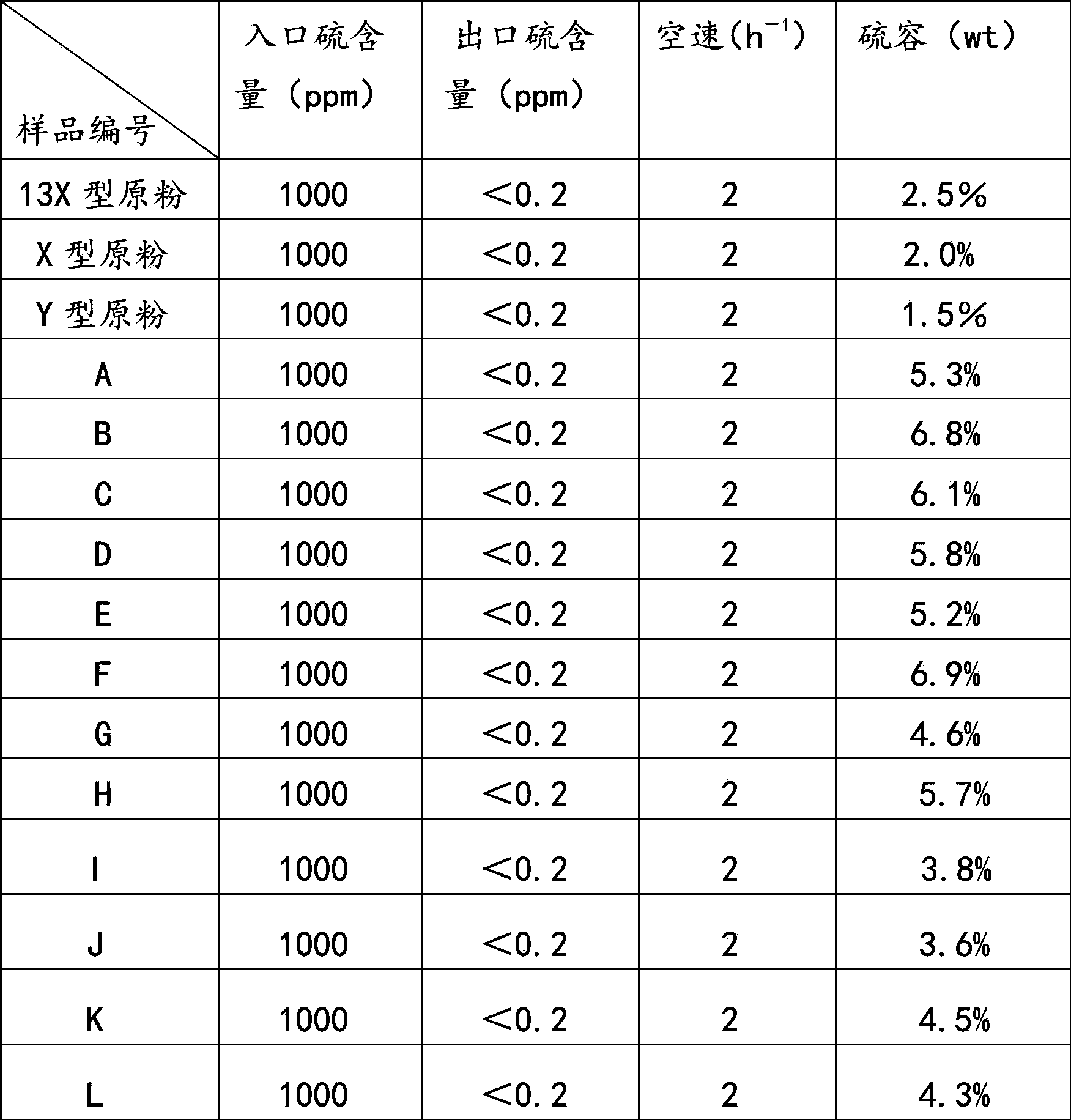

Embodiment 1

[0031] Configure 250mL exchange liquid, wherein the concentrations of potassium nitrate and copper nitrate are 0.025mol / L and 0.025mol / L respectively, weigh 40g of 13X type molecular sieve powder and add it to the above exchange liquid, ion exchange at normal temperature for 2 hours, The exchanged molecular sieves were filtered, separated, washed, dried at 70°C for 12 hours, and calcined at 500°C for 2 hours to obtain sample A. After analysis, it was found that the total exchange degree of metal copper and potassium cations was 10%.

Embodiment 2

[0033]Configure 250mL exchange liquid, wherein the concentrations of potassium nitrate and copper nitrate are 0.06mol / L and 0.04mol / L respectively, weigh 40g of 13X type molecular sieve powder and add it to the above exchange liquid, ion exchange at normal temperature for 36 hours, The exchanged molecular sieves were filtered, separated, washed, dried at 80°C for 8 hours, and calcined at 400°C for 4 hours to obtain sample B. After analysis, it was found that the total exchange degree of metal copper and potassium cations was 15%.

Embodiment 3

[0035] Configure 250mL exchange liquid, wherein the concentrations of potassium nitrate and copper nitrate are 0.1mol / L and 0.2mol / L respectively, weigh 40g of 13X type molecular sieve powder and add it to the above exchange liquid, ion exchange at normal temperature for 24 hours, The exchanged molecular sieves were filtered, separated, washed, dried at 90°C for 5 hours, and calcined at 350°C for 4 hours to obtain sample C. After analysis, it was found that the total exchange degree of metal copper and potassium cations was 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com