Method for producing aromatic hydrocarbon by low-olefin light hydrocarbon

A technology with low olefin content, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problem of low applicability of light hydrocarbon raw materials, achieve long single-pass operation cycle, prolong service life, and apply to the range of raw materials wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

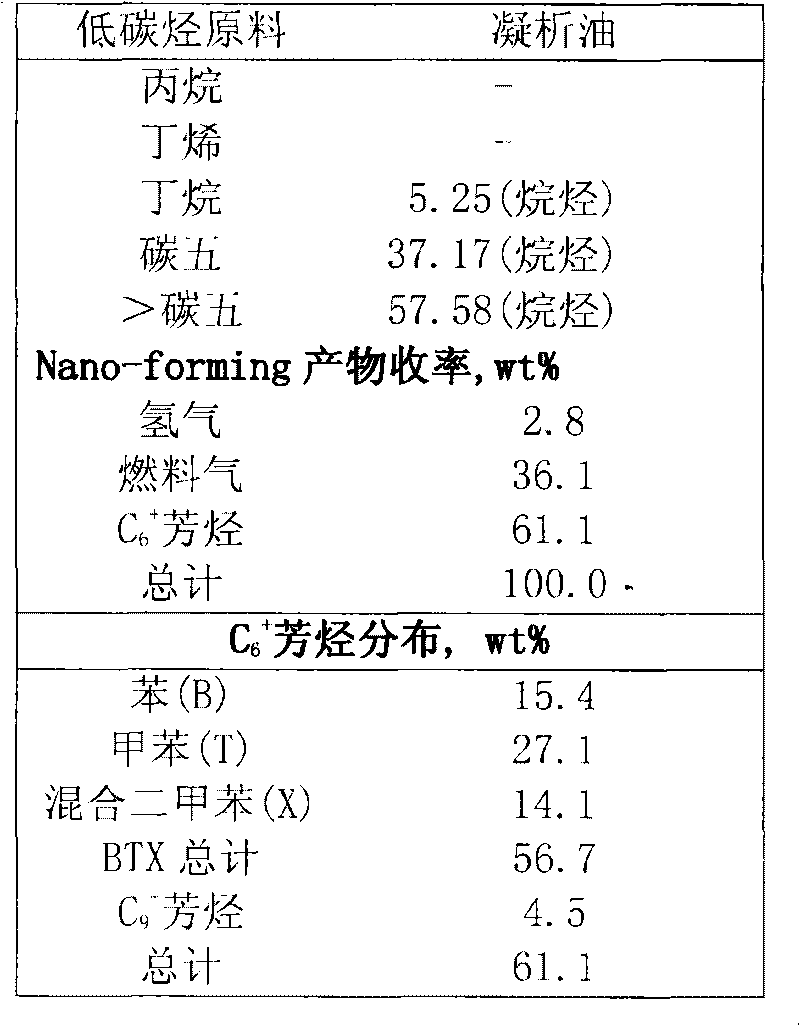

[0021] The production process adopts the Nano-forming process, specifically: the condensate oil pretreated by impurities is gasified by the feed evaporator and then enters the composite heating furnace to heat up to 450-570 ° C, and then enters the fixed-bed double reactor from top to bottom , Carry out aromatization reaction under the action of DLP type catalyst, reaction temperature 500℃-600℃, pressure 0-0.4MPa, space velocity 0.4-0.8h -1 . Most of the raw materials are converted into aromatic components such as benzene, toluene, and xylene, and at the same time, olefin-rich dry gases such as hydrogen, methane, ethylene, propane, and propylene are generated. The raw material composition and reaction effect are shown in Table 1.

[0022] Table 1 Main performance indicators of nano ZSM-5 type aromatization catalyst (DLP) for light hydrocarbons with low olefin content

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com