Slurry bubble column technology for preparing ethylene through acetylene hydrogenation and device thereof

A technology of acetylene hydrogenation and slurry bed, which is applied in hydrogenation hydrocarbon production, bulk chemical production, organic chemistry, etc. It can solve the problems that bed temperature cannot be effectively controlled, catalyst regeneration time increases, and bed treatment capacity is affected. Achieve the effect of long continuous operation time, increase reaction production capacity, increase reaction conversion rate and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

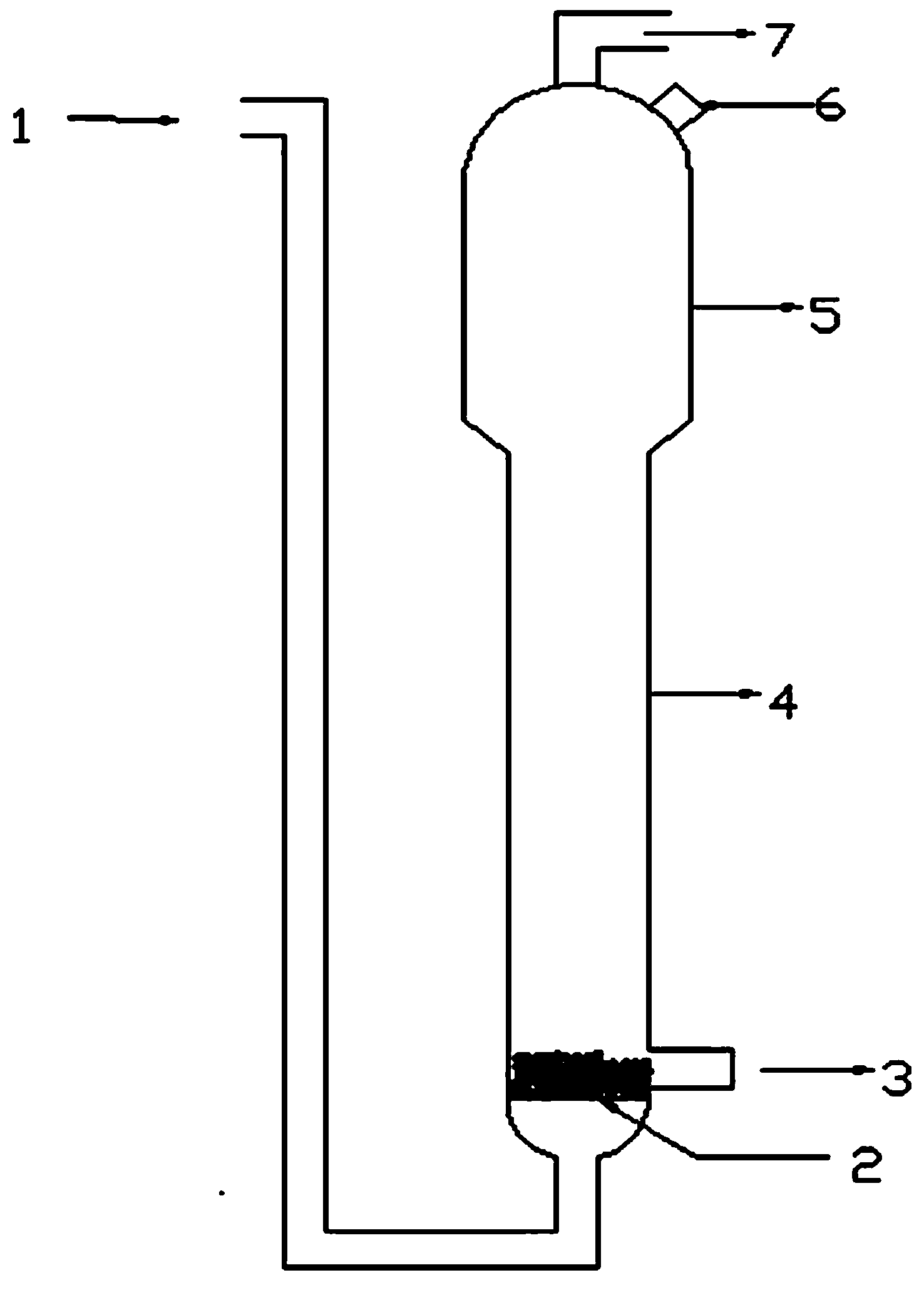

[0026] (1) In a slurry bed reactor with a height-to-diameter ratio of 11:1, add 80ml of water from the feed port 6 on the upper part of the reactor, and then add a particle size of 50mm and a carrier of Al 2 o 3 , 4g of catalyst particles with a loading of 0.3 wt% Pd, and the inert gas N was introduced from the reaction gas inlet 1 2 carry out atmosphere replacement;

[0027] (2) Heat the slurry bed reactor to 60°C;

[0028] (3) Pass the mixture of acetylene and hydrogen with a space velocity of 5000mL / (g-cat h) and a volume ratio of 1:1 into the slurry bed reaction through the gas distributor from the reaction gas inlet 1 at the bottom of the slurry bed reactor device, react at 90°C;

[0029] (4) The reaction product and unreacted raw material gas are discharged from the top of the slurry bed reactor and enter the separation section for separation to obtain ethylene products. The unreacted raw material gas is mixed with fresh raw material gas and re-enters the reactor for ...

Embodiment 2

[0032] (1) In a slurry bed reactor with a height-to-diameter ratio of 14:1, add 120ml of water from the feed port 6 on the upper part of the reactor, and then add SiO with a particle size of 100mm and a carrier 2 , 6g of catalyst particles with a loading of 0.03 wt% Pt, and the inert gas N was introduced from the reaction gas inlet 1 2 carry out atmosphere replacement;

[0033] (2) Heat the slurry bed reactor to 80°C;

[0034] (3) Pass the acetylene and hydrogen mixture with a space velocity of 1000mL / (g-cat h) and a volume ratio of 1:2 into the slurry bed reaction through the gas distributor from the reaction gas inlet 1 at the bottom of the slurry bed reactor device, react at 80°C;

[0035] (4) The reaction product and unreacted raw material gas are discharged from the top of the slurry bed reactor and enter the separation section for separation to obtain ethylene products. The unreacted raw material gas is mixed with fresh raw material gas and re-enters the reactor for re...

Embodiment 3

[0038] (1) In a slurry bed reactor with a height-to-diameter ratio of 15:1, add 200ml of water from the feed port 6 on the upper part of the reactor, and then add a particle size of 200mm, a carrier of activated carbon, and a Ni load of 1.0 wt%. 12g catalyst particles, and pass inert gas N from reaction gas inlet 1 2 carry out atmosphere replacement;

[0039] (2) Heat the slurry bed reactor to 90°C;

[0040] (3) Pass the acetylene and hydrogen mixture with a space velocity of 10000mL / (g-cat h) and a volume ratio of 1:3 into the slurry bed reaction through the gas distributor from the reaction gas inlet 1 at the bottom of the slurry bed reactor device, react at 100°C;

[0041] (4) The reaction product and unreacted raw material gas are discharged from the top of the slurry bed reactor and enter the separation section for separation to obtain ethylene products. The unreacted raw material gas is mixed with fresh raw material gas and re-enters the reactor for recycling.

[0042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com