Novel composite alkalizer and application thereof

An alkalizing agent and alkaline technology, which is applied in chemical instruments and methods, water treatment parameter control, neutralized water/sewage treatment, etc., can solve the problems of high operating cost and increase the operating burden of mixed beds, so as to reduce the operating burden , reduce adverse effects, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The composition of the new composite alkalizing agent: ethanolamine (ETA), ammonia (NH 3 )

[0034] The initial mass concentration ratio of the new composite alkalizing agent: [ETA] / [NH 3 ]=2:1;

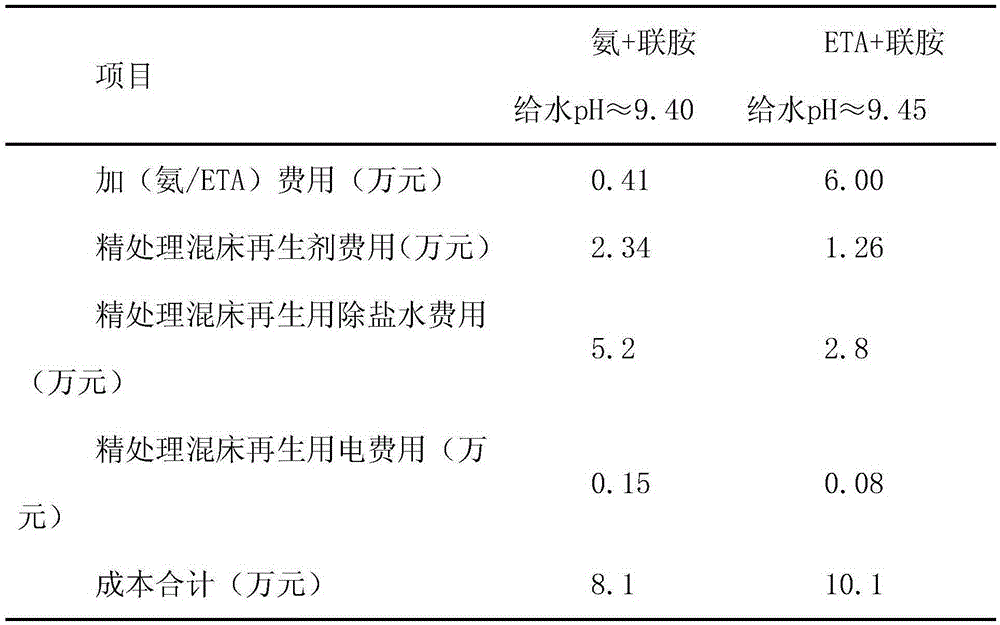

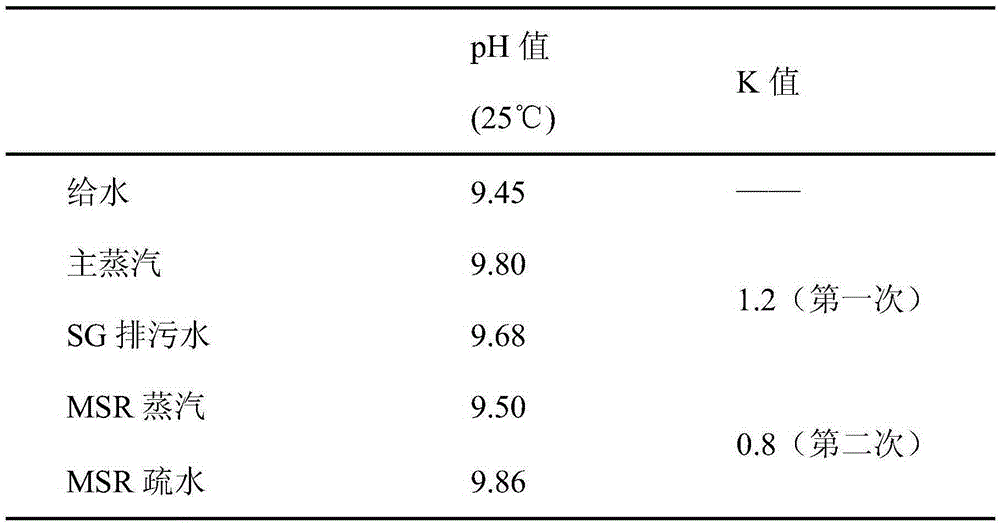

[0035] Table 2 The monitoring value of the new compound alkalization agent used in the secondary circuit of nuclear power plant

[0036]

example 2

[0038] Composition of new compound alkalizing agent: 5-aminopentanol (5-AP), dimethylamine (DMA)

[0039] The initial mass concentration ratio of the new composite alkalizing agent: [5-AP] / [DMA]=1:1;

[0040] Table 3 The monitoring value of the new compound alkalization agent used in the secondary circuit of nuclear power plant

[0041]

[0042]

example 3

[0044] The composition of the new composite alkalizing agent: ethanolamine (ETA), ammonia (NH 3 ), Morpholine (MPH)

[0045] The initial mass concentration ratio of the new composite alkalizing agent: [ETA] / [NH 3 ] / [MPH]=1:1:2;

[0046] Table 4 The monitoring value of the new compound alkalization agent used in the secondary circuit of nuclear power plant

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com