Intelligent control system for refined sugar resin decolorization and regeneration

An intelligent control system and control system technology, applied in control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problems of high equipment cost and high maintenance cost, save regeneration fluid and reduce resin loss , suitable for large-scale production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the implementation cases of the present invention.

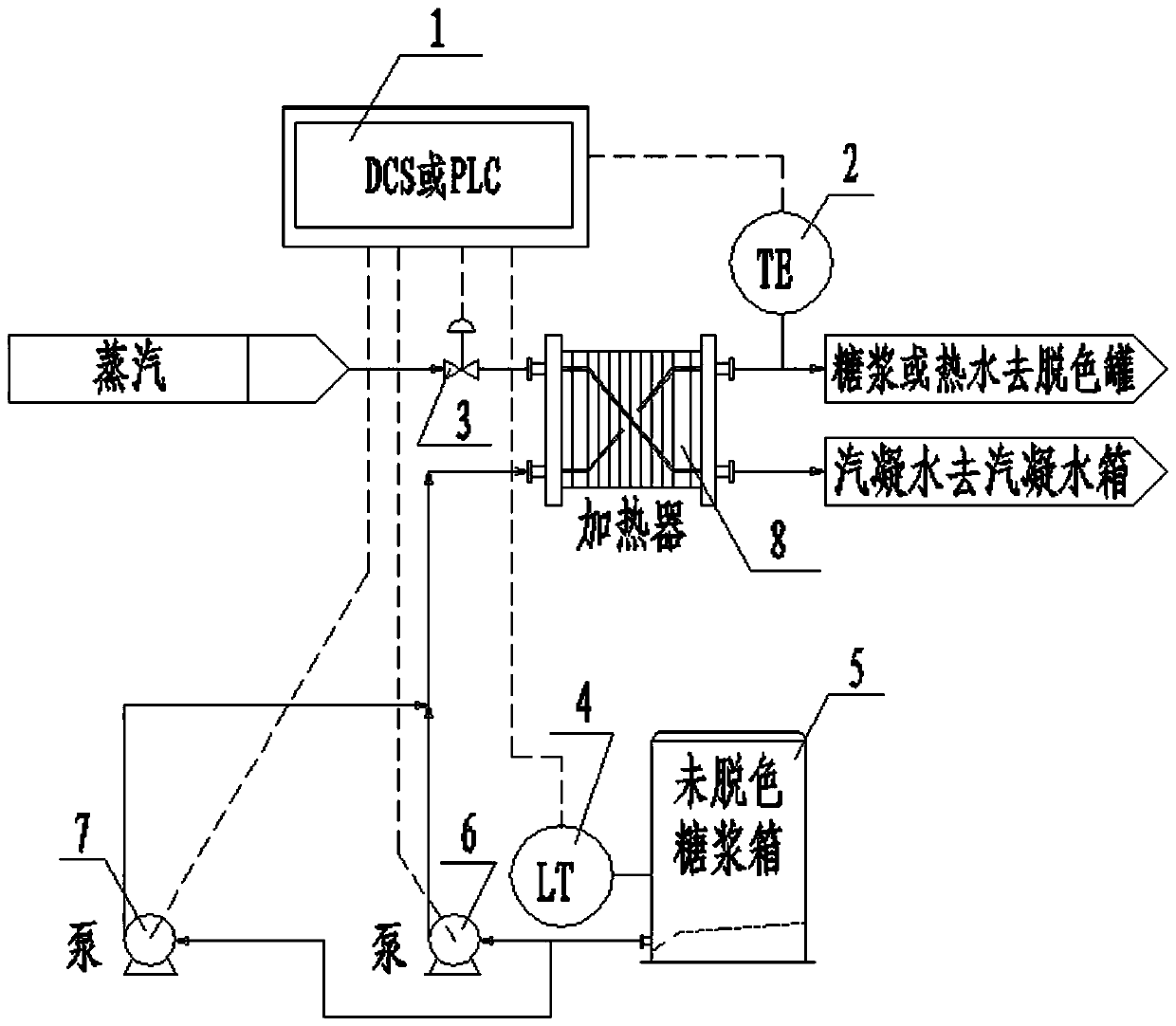

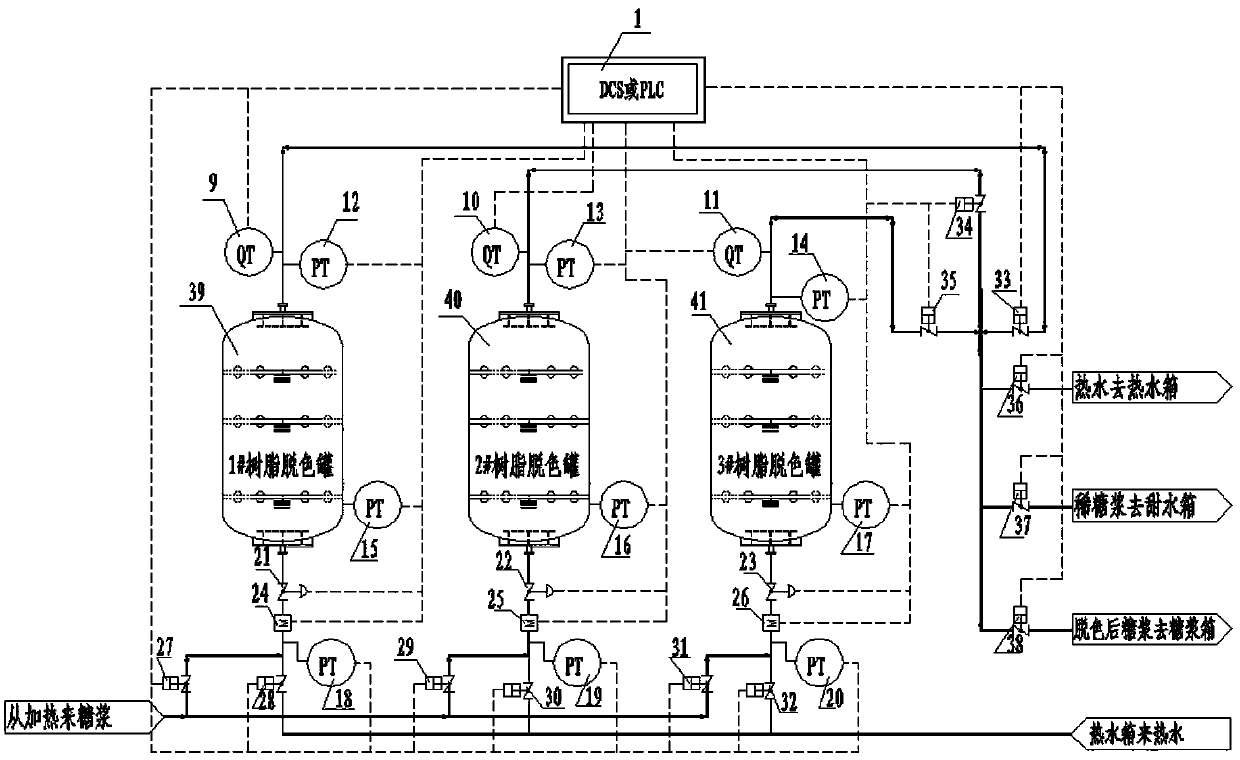

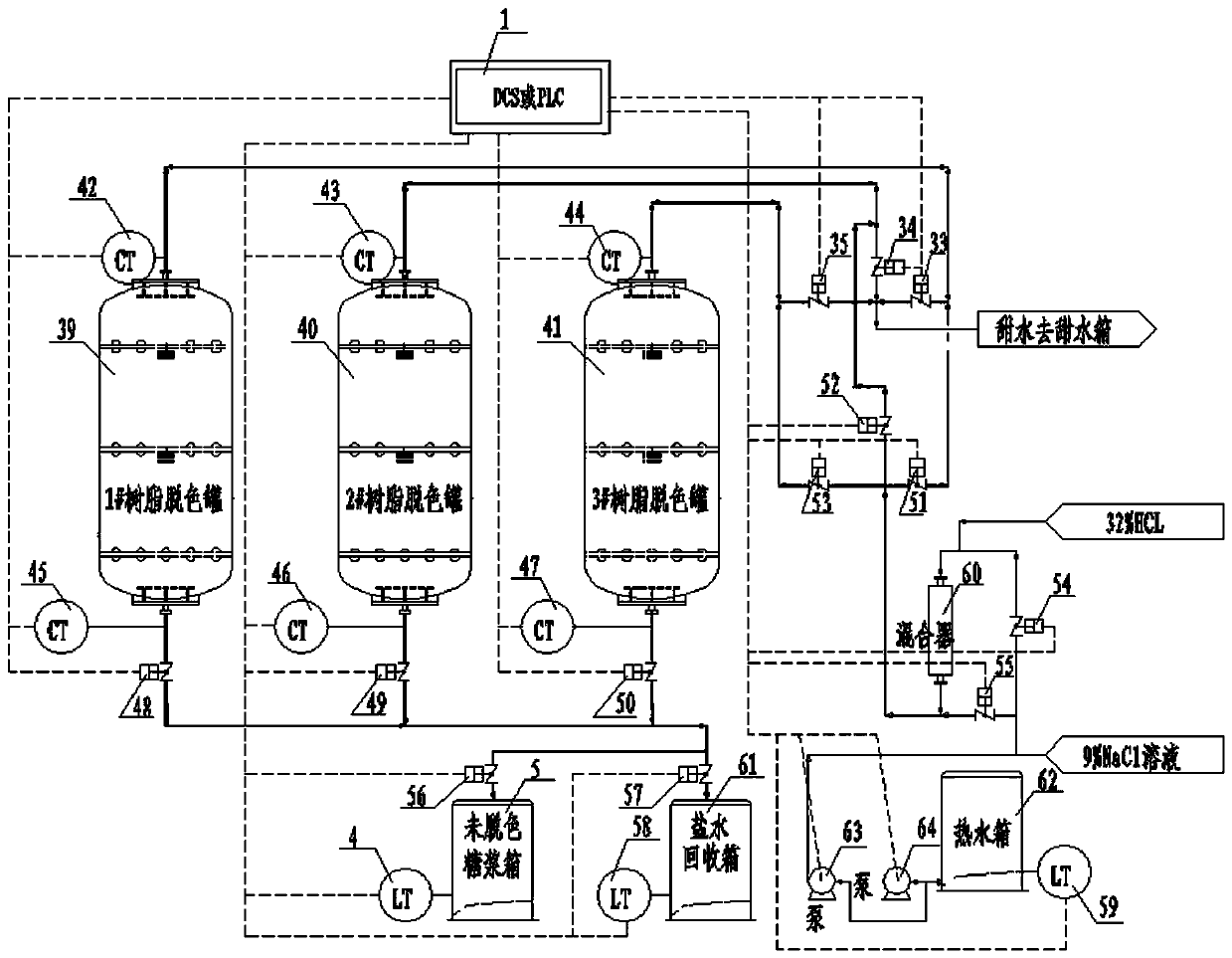

[0054] An intelligent control system for decolorization and regeneration of refined sugar resin, including a DCS or PLC control system, which outputs signals to related equipment through the DCS or PLC control system to control the temperature and flow rate of syrup entering the resin decolorization tank, so as to realize decolorization and decolorization of refined sugar resin. Intelligent control of sugar and regeneration process, related equipment includes resin decolorization tank, hot water tank, undecolorized syrup tank, brine recovery tank, pump, mixer and connecting pipes; The water tank is connected to the heater, and the pipes at the top of each resin decolorization tank are combined to connect the hot water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com