Broken rice dehydration and recovery device for glucose syrup production and processing

A glucose syrup and recovery device technology, applied in the field of glucose production, can solve the problems of waste of water resources and sugar liquid, increase the burden of sewage treatment equipment, etc., achieve the effects of reducing the loss of sugar liquid, improving convenience, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further description will be given below in conjunction with the drawings in the embodiments of the present invention.

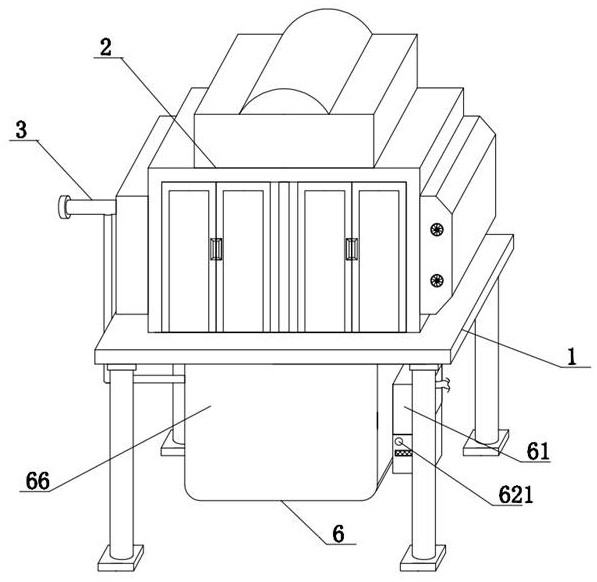

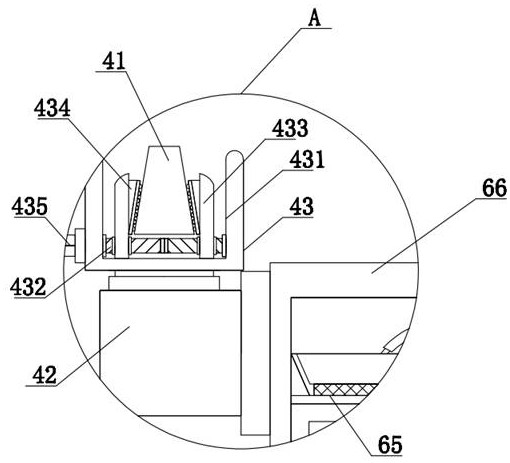

[0027] see figure 1 , a crushed rice dehydration recovery device for glucose syrup production and processing, comprising an operation console 1, a production equipment body 2 is fixedly installed on the top of the operation console 1, a rice grinding water supply pipe 3 is fixedly installed on the left side of the production equipment body 2, and the operation console 1 There are fixing mechanisms 4 at the four corners of the bottom, the bottom of the operating table 1 is fixedly installed with a recovery mechanism 6 through the fixing mechanism 4, and the middle of the bottom of the operating table 1 is fixedly installed with a leaking funnel 5, and the lower end of the leaking funnel 5 communicates with the recycling mechanism 6 ;

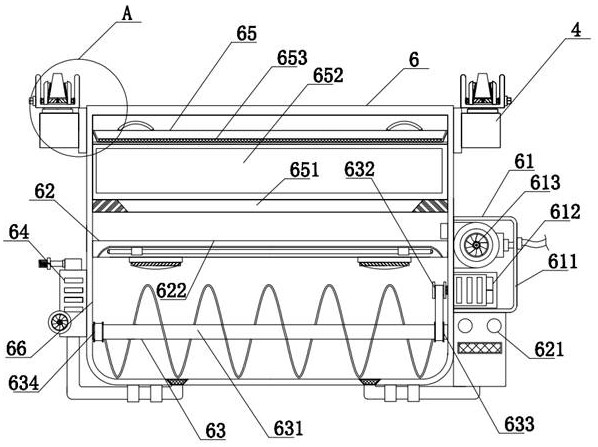

[0028] Recovery mechanism 6 comprises recovery box 66, and the inner upper end of recovery box 66 is provided with fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com