Modified activated carbon and composite material as well as preparation methods and application thereof

A composite material and activated carbon technology, applied in the field of desulfurization, can solve problems such as difficult to balance desulfurization rate and penetration sulfur capacity, and achieve the effects of promoting development, good regeneration performance, and high penetration sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

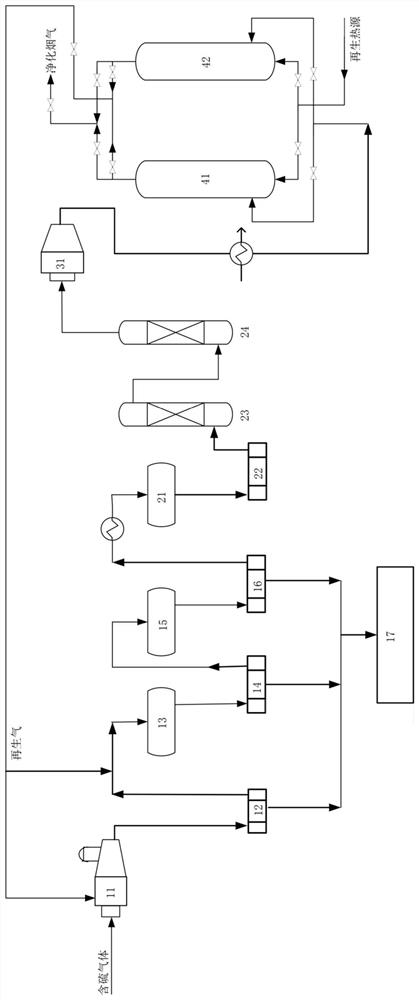

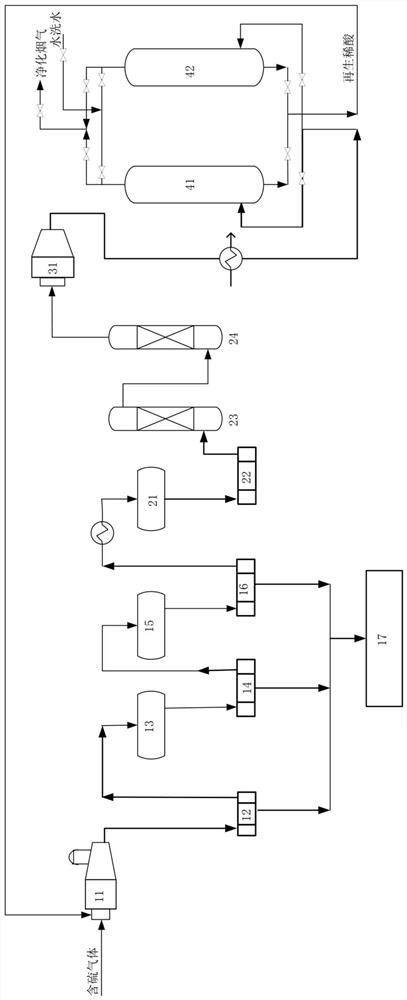

Image

Examples

preparation example Construction

[0053] According to the method for preparing modified activated carbon of the present invention, the amount of the precursor of the activated carbon and the alkali metal makes the weight ratio between the activated carbon and the alkali metal element in the obtained modified activated carbon preferably 100:(0.5-2).

[0054] According to the method for preparing modified activated carbon of the present invention, the amount of the activated carbon and the silicon-containing binder is such that the weight ratio between activated carbon and silicon in the obtained modified activated carbon is preferably 100:(1-2.8).

[0055] According to the method for preparing modified activated carbon of the present invention, the activated carbon can be various common activated carbons, preferably, the specific surface area of the activated carbon is ≥700m 2 / g, more preferably 700-1000m 2 / g.

[0056] According to the method for preparing modified activated carbon of the present invention...

Embodiment approach

[0078] According to another embodiment of the present invention, the present invention provides a kind of method for preparing composite material, it is characterized in that, this method comprises:

[0079] (1) In the presence of a solvent, knead, shape, dry and roast activated carbon, the precursor of an alkali metal, a silicon-containing binder and an optional pore-enlarging agent to obtain a modified activated carbon, wherein the activated carbon , the precursor of alkali metal and the consumption of silicon-containing binder make the weight ratio between activated carbon, alkali metal element and silicon element in the gained modified activated carbon be 100:(0.2-3):(0.8-5);

[0080] (2) The precursor of the active component is contacted with the modified activated carbon so that the modified activated carbon is loaded with the active component, wherein the precursor of the active component contains a precursor of iron and a rare earth element , the amount of the precurso...

Embodiment 1

[0155] This example is used to illustrate the composite material (or adsorbent) of the present invention and its preparation method.

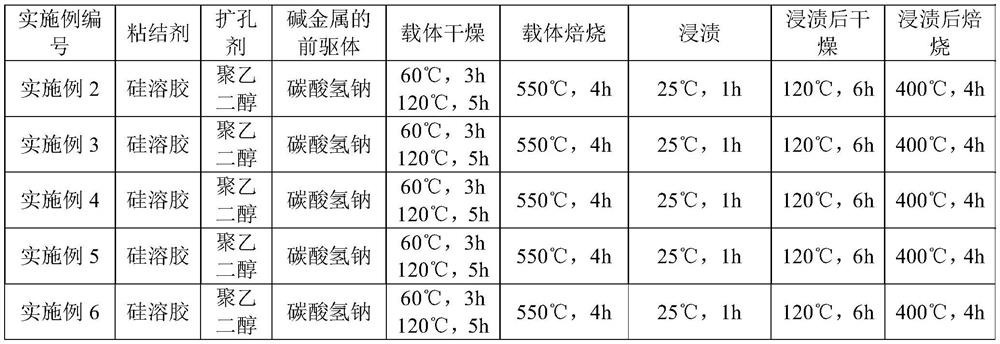

[0156] Weigh 925g specific surface area is 906m 2 The coconut shell activated carbon of / g, 32.67g purity are the sodium bicarbonate of 99% by weight, the polyethylene glycol that 28g purity is 99% by weight, the three are mixed uniformly to form material A.

[0157] Weigh 66.67g alkaline silica sol (SiO 2 content is 30% by weight), the silica sol was dissolved into 360g of deionized water, stirred evenly, and prepared as a binder.

[0158] The binder is added to the material A, and extruded on the extruder to obtain The strip-shaped material obtained is first dried at 60°C for 3 hours, then dried at 120°C for 5h, and then calcined at 550°C for 4 hours to obtain modified activated carbon (or adsorbent carrier), and its specific surface area and The pore volume was measured, and the results are shown in Table 4.

[0159] Take by weighing 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com