Catalyst for removing mercaptan in natural gas, and preparation method thereof

A catalyst and natural gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as low sulfur removal rate, and achieve the effects of low reaction temperature, good regeneration performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

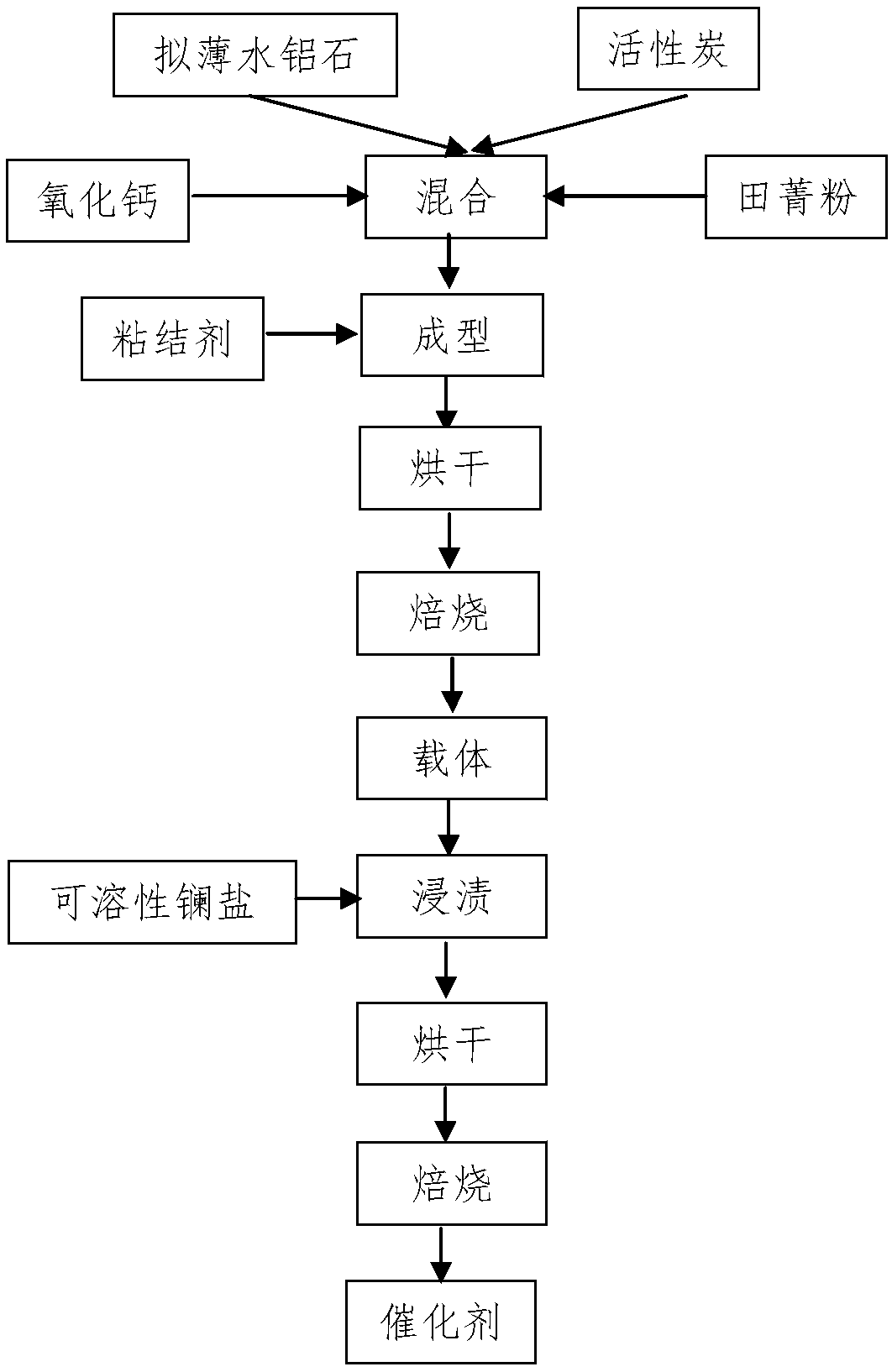

Method used

Image

Examples

Embodiment 1

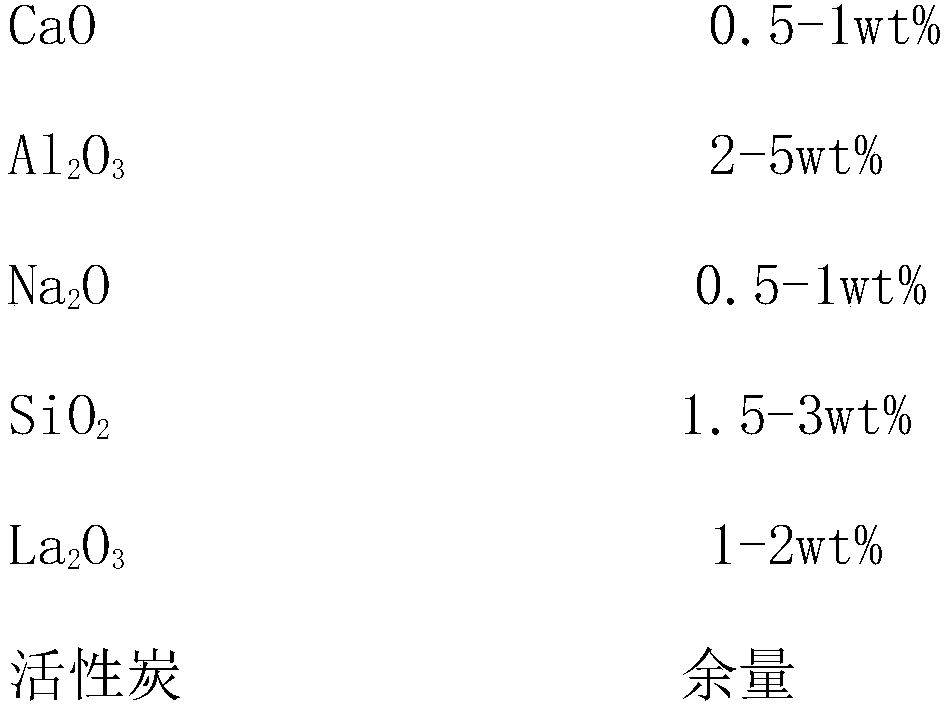

[0042] Weigh 923.47 grams of specific surface area to 982m 2 / g coconut shell activated carbon, 42.86g specific surface area 411m 2 / g, pore volume 0.96ml / g pseudo-boehmite, 10.10 grams of calcium oxide with a purity of 99%, 30.30 grams of sesame powder with a purity of 99%, the four are evenly mixed to form material A. Measure 122ml water glass solution (SiO 2 250g / L, Na 2 O is 82g / L), dissolve the water glass in water, stir evenly, and configure it as a binder. The binder was added to material A, extruded on an extruder, dried at 120°C for 4 hours, and calcined at 600°C for 4 hours to prepare a catalyst carrier.

[0043] Catalyst active component La 2 O 3 Calculated by 1.5% of the weight of the catalyst, 40.85 grams of lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) Dissolve in deionized water, stir evenly to form a stable solution, obtain the active component impregnation solution according to the added amount of the carrier, and impregnate the catalyst according to the equ...

Embodiment 2-7

[0045] The activated carbon catalyst was prepared according to the steps and conditions of Example 1, except that the concentration, composition or preparation conditions of the impregnation solution were changed. The changed conditions are listed in Table 1.

[0046] Table 1 Example catalyst composition

[0047] Catalyst / wt% CaONa 2 O

Embodiment 8

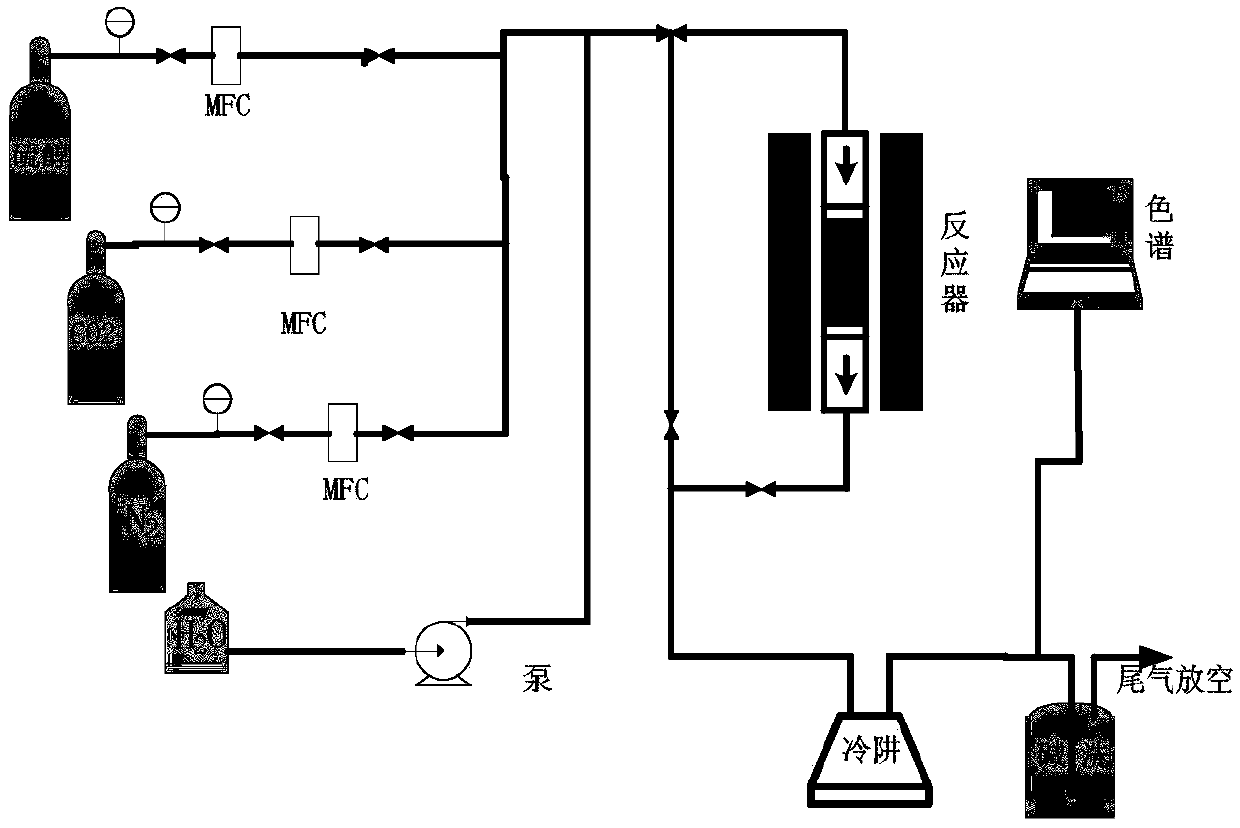

[0055] Catalyst evaluation method

[0056] The reactor of the micro reaction device is made of a stainless steel tube with an inner diameter of 20 mm, and the reactor is placed in a thermostat. The catalyst is filled with 10ml, and the upper part is filled with quartz sand of the same size for mixing and preheating. The content of methyl mercaptan in the inlet and outlet gas of the reactor was analyzed by the spectrosulfur chromatograph produced by AC Company.

[0057] Chromatographic operating conditions

[0058] Detector: SCD;

[0059] Chromatographic column: stainless steel column length 30m, inner diameter 0.32mm, liquid film thickness 4μm; liquid film specification PDMS-1

[0060] Column temperature: 250℃

[0061] Detector temperature: 950℃

[0062] Gasification chamber temperature: 275℃

[0063] Carrier gas (N 2 ) Flow rate: 90ml / min;

[0064] Injection volume: 1μL.

[0065] The inlet gas volume composition is CO 2 3%, CH 3 SH 0.01%, H 2 O 3%, the rest is N 2 , The gas volumetric sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com