Preparation method of three-dimensional ordered macroporous ferric oxide desulfurizer

An iron oxide desulfurizer, three-dimensional ordered technology, applied in the preparation and application field of three-dimensional ordered macroporous iron oxide desulfurizer, can solve the problems of low utilization rate of desulfurizer, low desulfurization efficiency, small space velocity, etc. To achieve the effect of detailed and accurate process parameter data, less equipment used and high desulfurization precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with accompanying drawing:

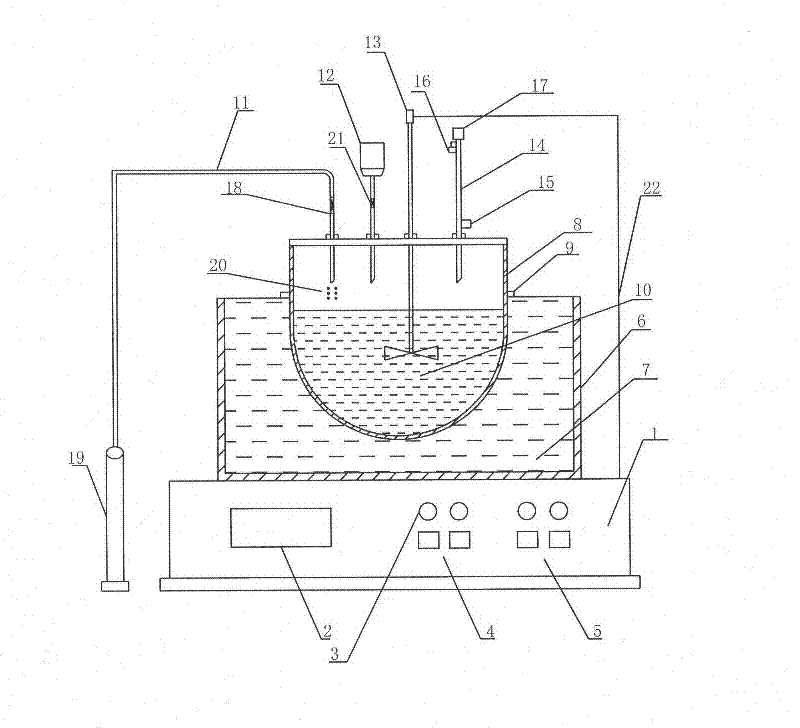

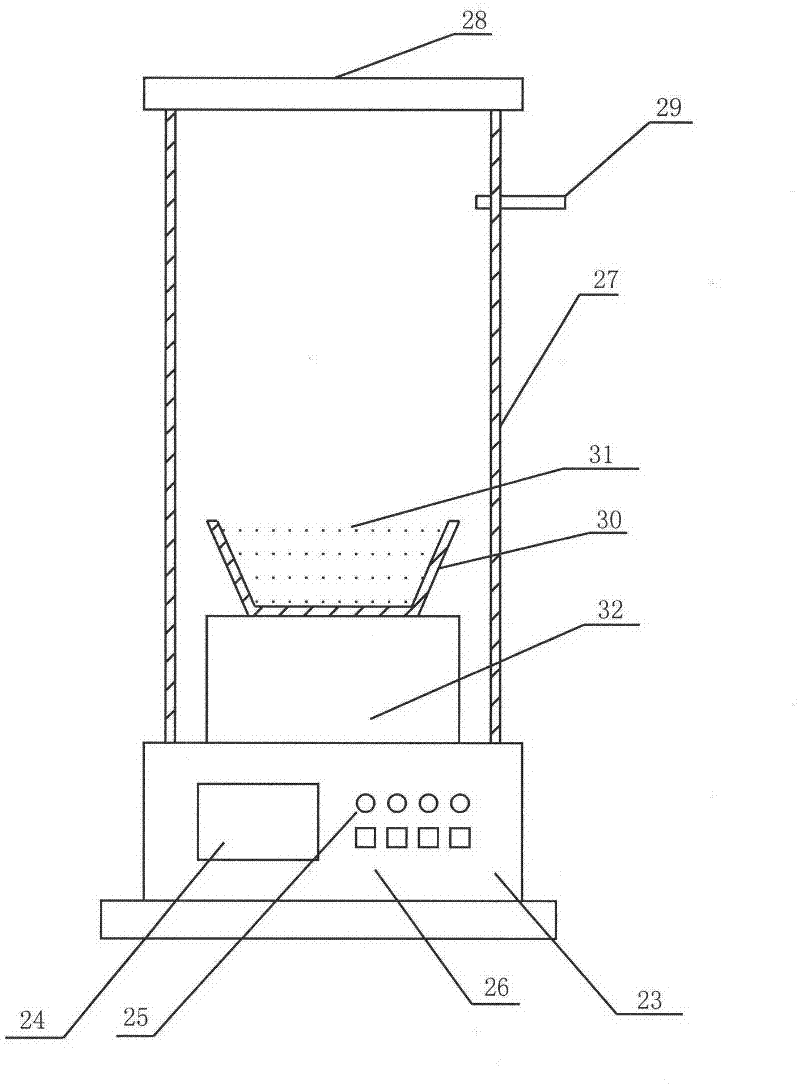

[0070] figure 1 As shown, it is a state diagram for preparing polystyrene microspheres. As shown in the diagram, the positions of each part must be correct, and the ratio should be adjusted according to the amount, and the operations should be performed in sequence.

[0071] The chemical substances used in the preparation are determined according to the pre-set range, in grams, milliliters, centimeters 3 is the unit of measurement.

[0072] The preparation of polystyrene microspheres is carried out in a four-necked flask, which is completed under heating, water bath, stirring, nitrogen protection, and water cycle condensation; the four-necked flask 8 is placed on the water bathtub 6, and the water bathtub 6 has a built-in water bath Water 7, water bath water 7 should submerge 4 / 5 of the volume of the four-necked flask 8; water bath 6 is placed on the electric controller 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com