Low-temperature carbonyl sulfide hydrolysis activated carbon-supported catalyst and preparation method thereof

A carbon-based catalyst, carbonyl sulfide technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen sulfide, etc., can solve the problems of high equilibrium conversion rate, high operating cost, waste of energy, etc., and achieve good activity at room temperature and low temperature , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take 10g of LJ-40 activated carbon, grind it with a bowl, and sieve it to 40-60 mesh, wash it with tap water and distilled water for 3-4 times, then boil it with 1mol / L KOH solution for 1.5h, then wash it with distilled water Wash until the pH is constant, and dry in a constant temperature drying oven at 120°C for 3 hours;

[0024] (2), weigh 0.16g KMnO 4 Add 3ml of distilled water, and take 3g of activated carbon pretreated in step (1) for ultrasonic impregnation for 30min;

[0025] (3), dry the impregnated activated carbon in step (2) in a constant temperature drying oven at 120°C for 3h, then put it into a muffle furnace, and activate it at 300°C for 3h;

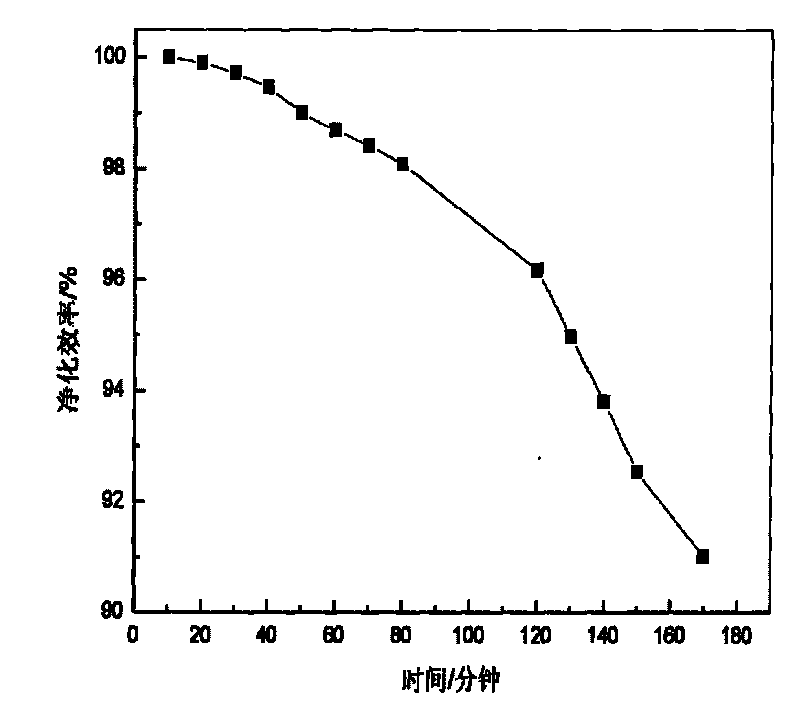

[0026] (4) Weigh 0.29g KOH and add it into 3ml distilled water, ultrasonically impregnate the activated carbon activated in step (3) for 30min, and then keep the temperature at 120°C for 3h to obtain the activated carbon-based catalyst. The reaction conditions for the activity test are: temperature 50°C , Air...

Embodiment 2

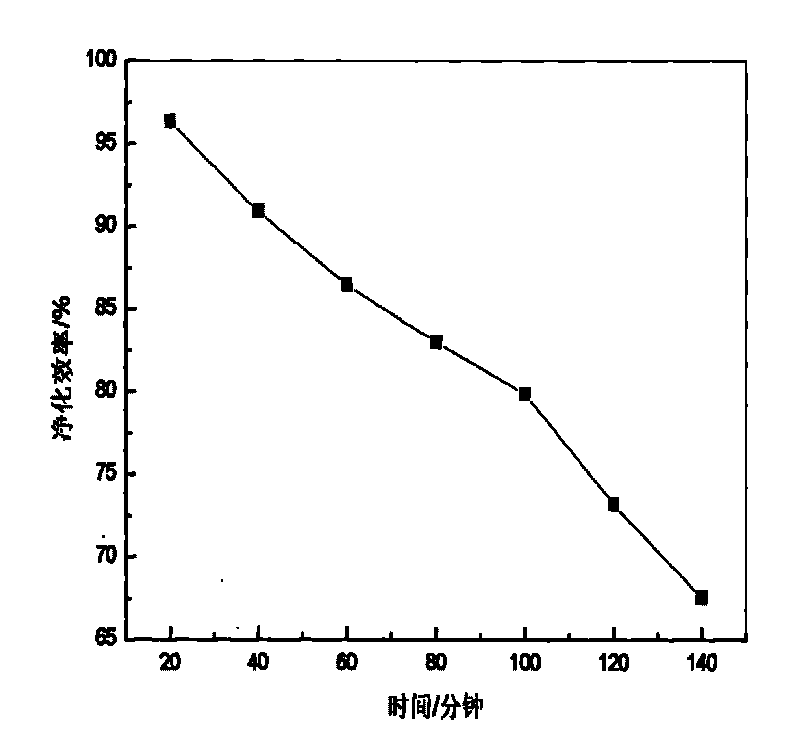

[0028] According to the method of embodiment 1, change and weigh KMnO 4 The amount of KOH was 0.49g, and 0.55g KOH was weighed to obtain the catalyst. Activity test reaction conditions are: temperature 50°C, space velocity 1000h -1 , COS concentration 1400mg / m 3 , no H was detected at the reaction outlet 2 S, whose activity see figure 2 .

Embodiment 3

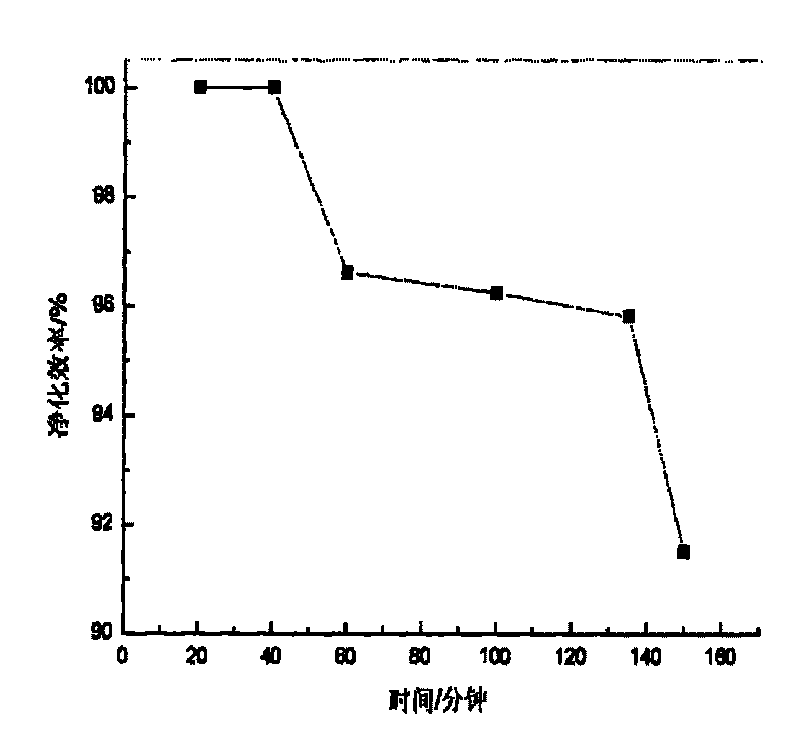

[0030] According to the method of embodiment 1, take by weighing 0.1g Na 2 CO 3 , changing the calcination temperature to 700°C to obtain the catalyst. Activity test reaction conditions are: temperature 50°C, space velocity 1000h -1 , COS concentration 1400mg / m 3 , no H was detected at the reaction outlet 2 S, whose activity see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com